Mixture for preparing nylon nano composite material and preparation method of composite material

A technology of nanocomposite materials and mixtures, which is applied in the field of preparation of nylon nanocomposite mixtures, which can solve the problems that other properties have not been improved, and achieve the effect of balancing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

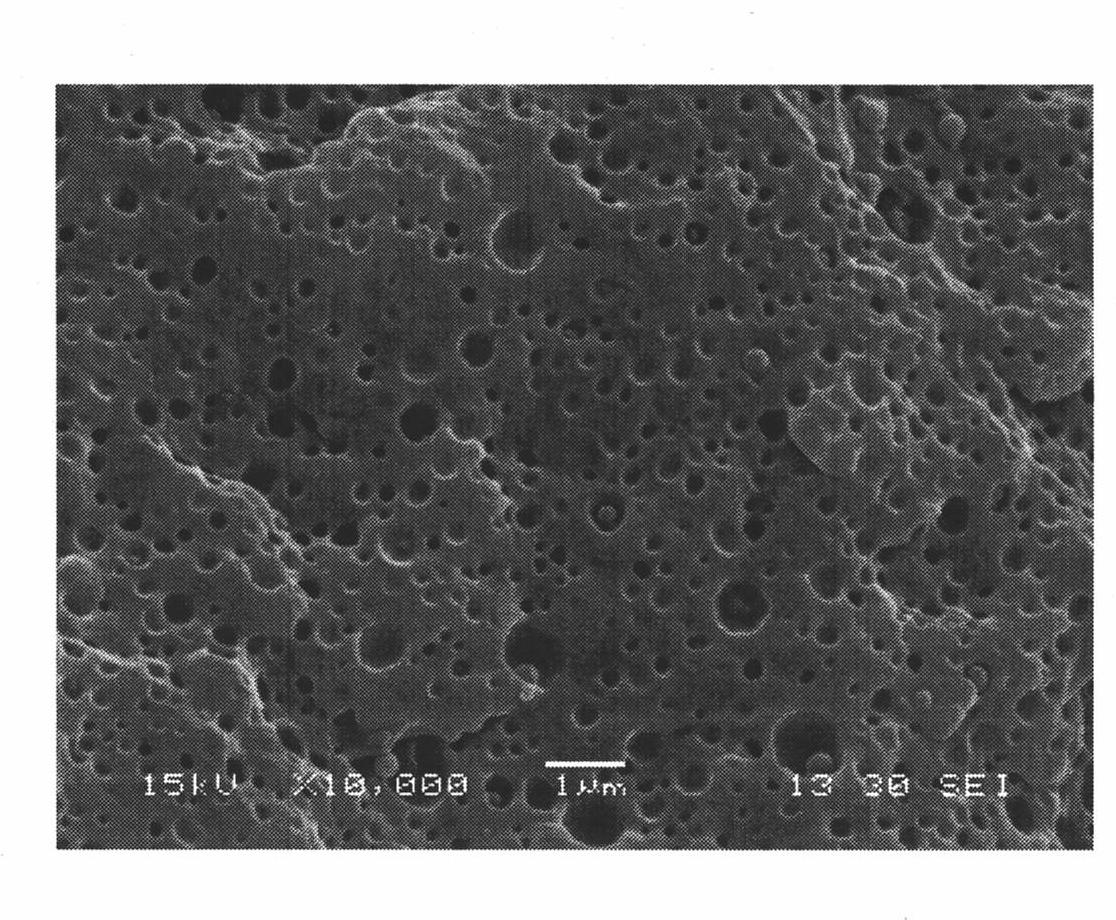

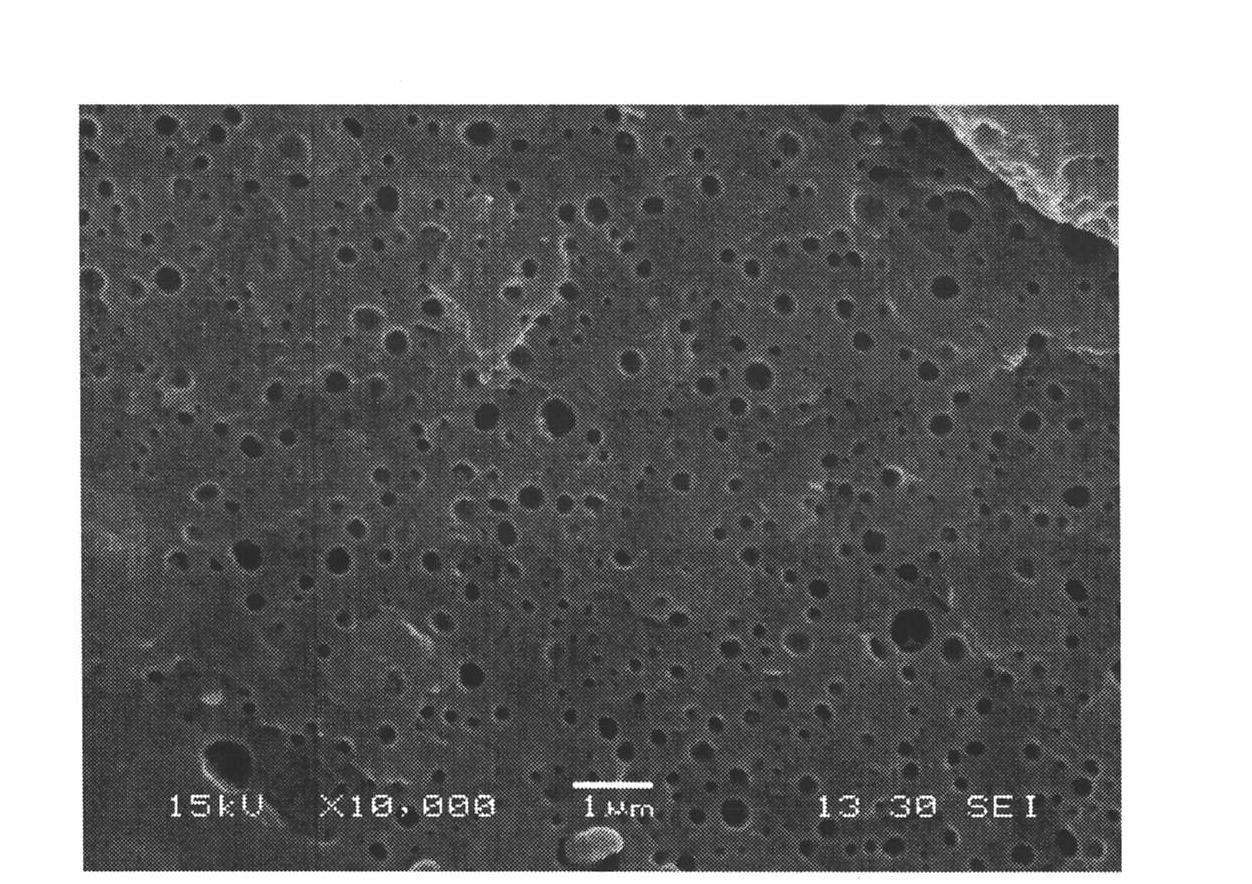

Image

Examples

Embodiment Construction

[0020] The present invention is described further below by embodiment, and its purpose is for better understanding content of the present invention. Therefore, the examples given do not limit the protection scope of the present invention:

[0021] The process conditions that following embodiment 1-8 and comparative example 1-5 adopt are:

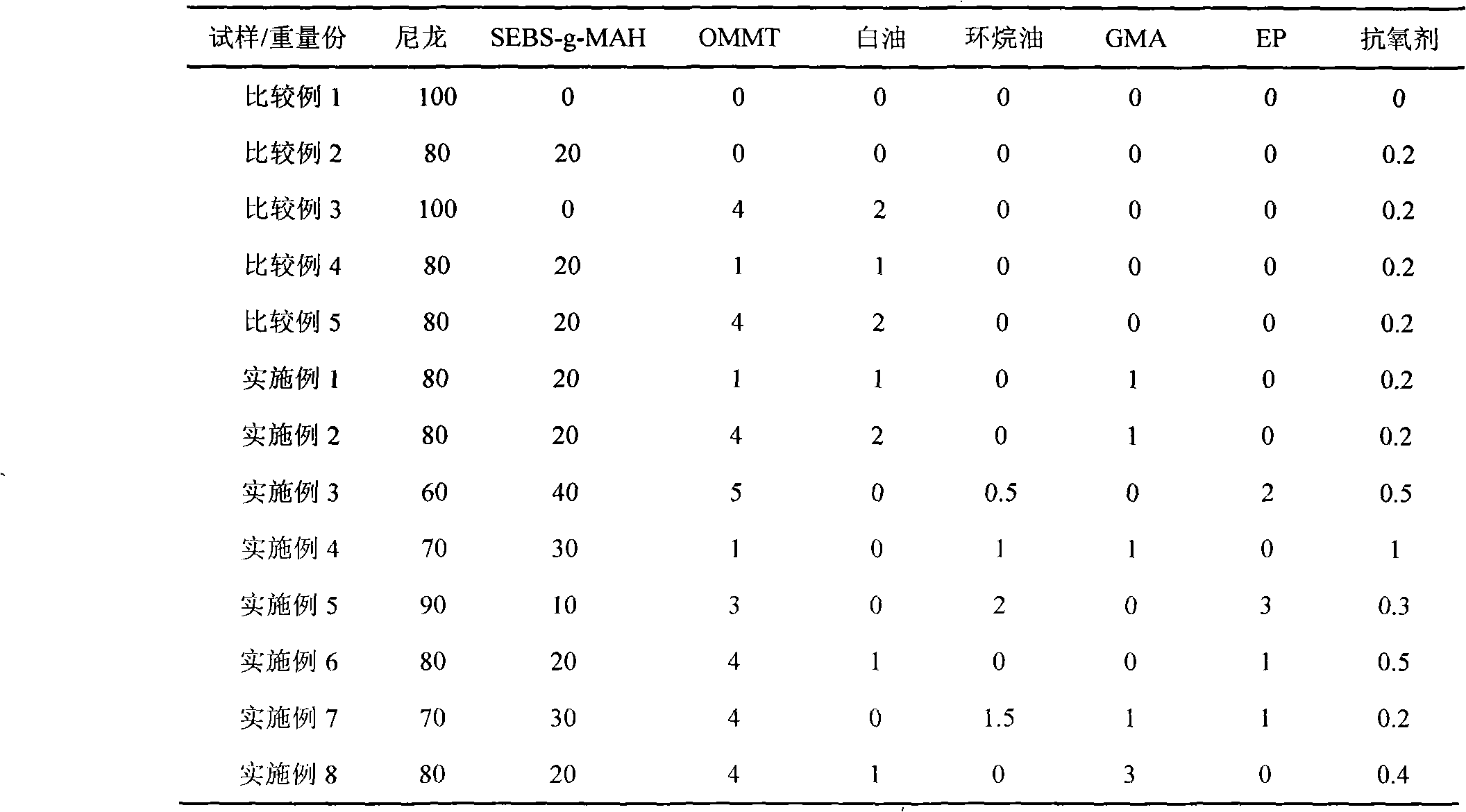

[0022] After vacuum drying nylon, SEBS-g-MAH and OMMT at 80°C, mix them with dispersant, compatibilizer and antioxidant according to the composition ratio shown in Table 1, and then use a twin-screw extrusion machine melt extrusion. Control the temperature of each section of the screw: 200°C, 230°C, 240°C, 240°C, 240°C, and 235°C from the feeding port to the outlet of the machine head, of which the temperature of the feeding section is 200 °C, the temperature of the machine head is 235 °C, and others is the temperature of the plasticizing shear section, the twin-screw speed is 100 revolutions per minute, and the residence time of the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com