Dropped initiation device

A detonating device and drop-in technology, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling and mining, etc., can solve the problems of lowering safety, misfiring of the detonator, throwing rods and hanging rods, etc., to reduce construction costs, Achieve safe operation and eliminate potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

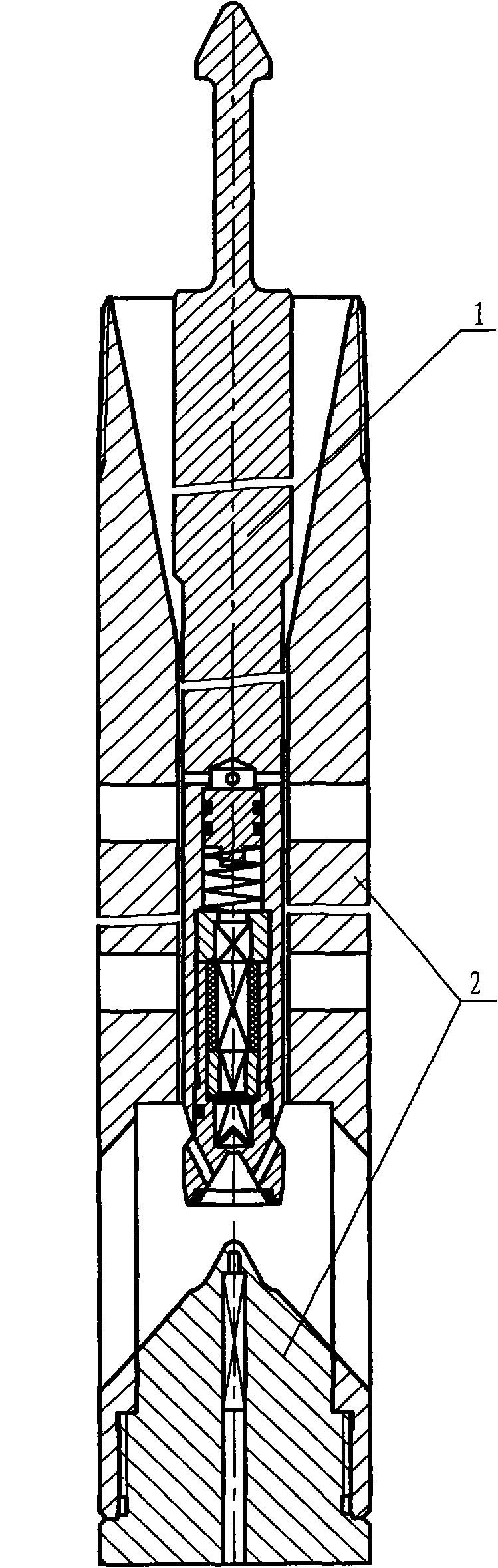

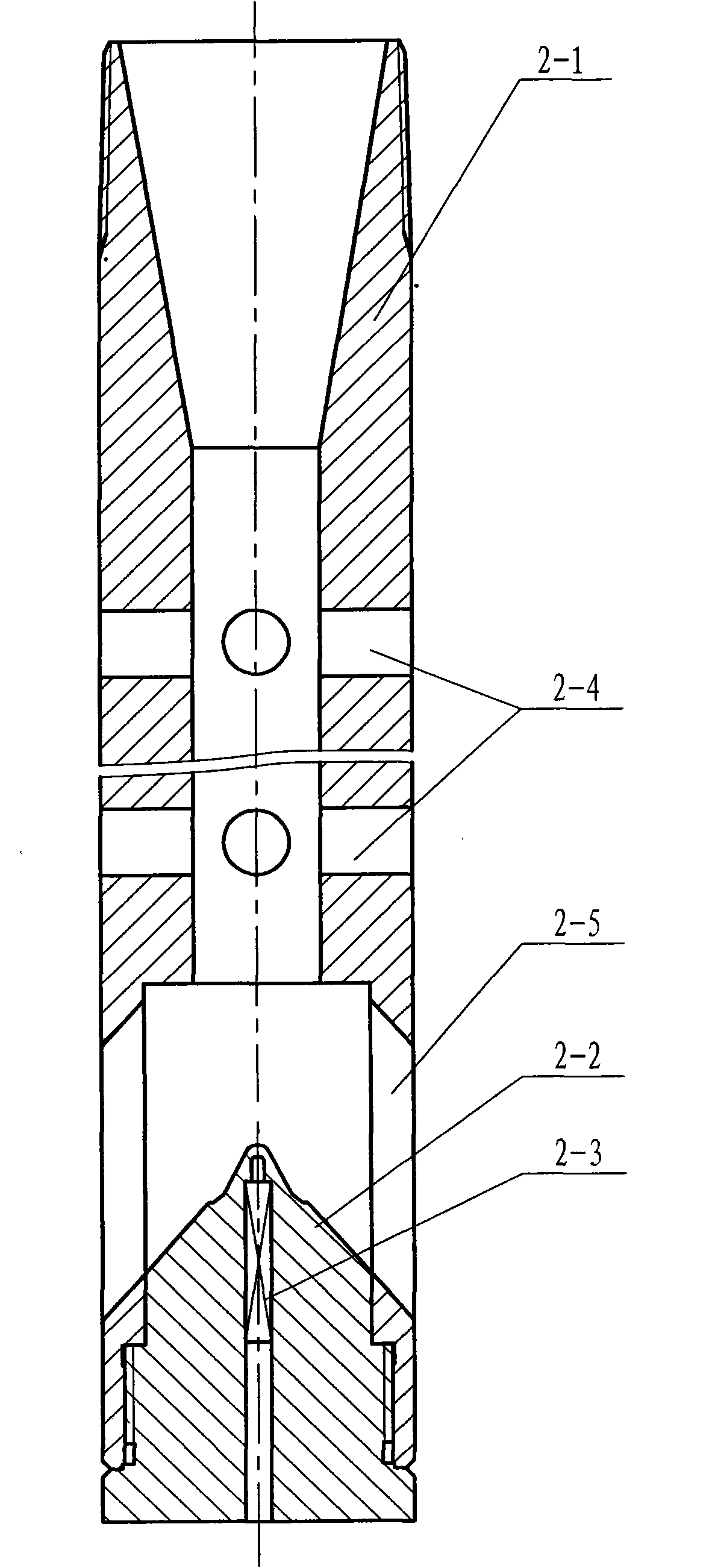

[0020] as figure 1 As shown, the first preferred embodiment of the drop-in detonator of the present invention is composed of a drop-in detonator 1 and an explosion-transfer joint 2. In the non-use state, the drop-in detonator 1 and the explosion-transfer joint 2 are independent.

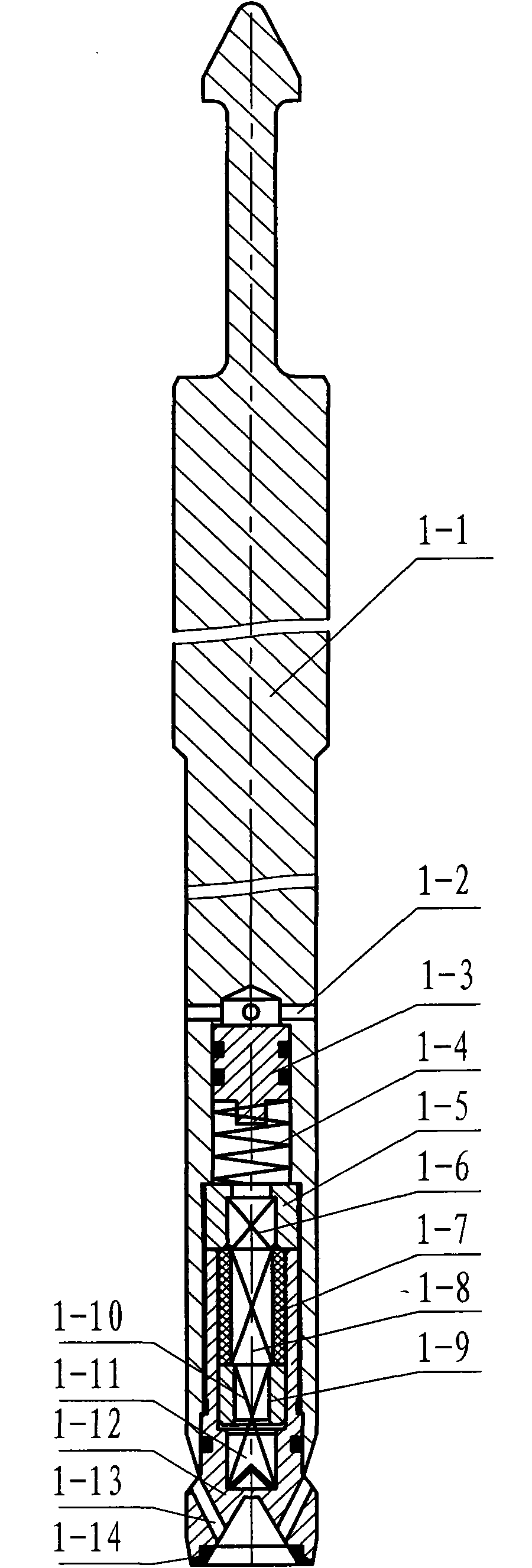

[0021] according to figure 2 As shown, the delivery detonator 1 includes a rod body 1-1, a delayed firing mechanism, pyrotechnic components, a rod tip 1-11 and a rubber pad 1-12. The upper end of the rod body 1-1 is provided with a fishing head, and the lower end is provided with a first blind hole along the axis. The first blind hole is a two-step stepped hole. The outermost hole of the first blind hole is provided with a female thread. The first blind hole The minimum hole at the bottom of the bottom is provided with a plurality of inlet pressure passa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com