Automatic blending control method of oil field fracturing fluid

A technology for oil field fracturing and control methods, which is applied in earth-moving drilling, production fluids, wellbore/well components, etc., can solve the problems of uneven viscosity, long natural swelling time, poor mixing quality, etc., and achieves uniform viscosity, The effect of saving labor intensity and facilitating data analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

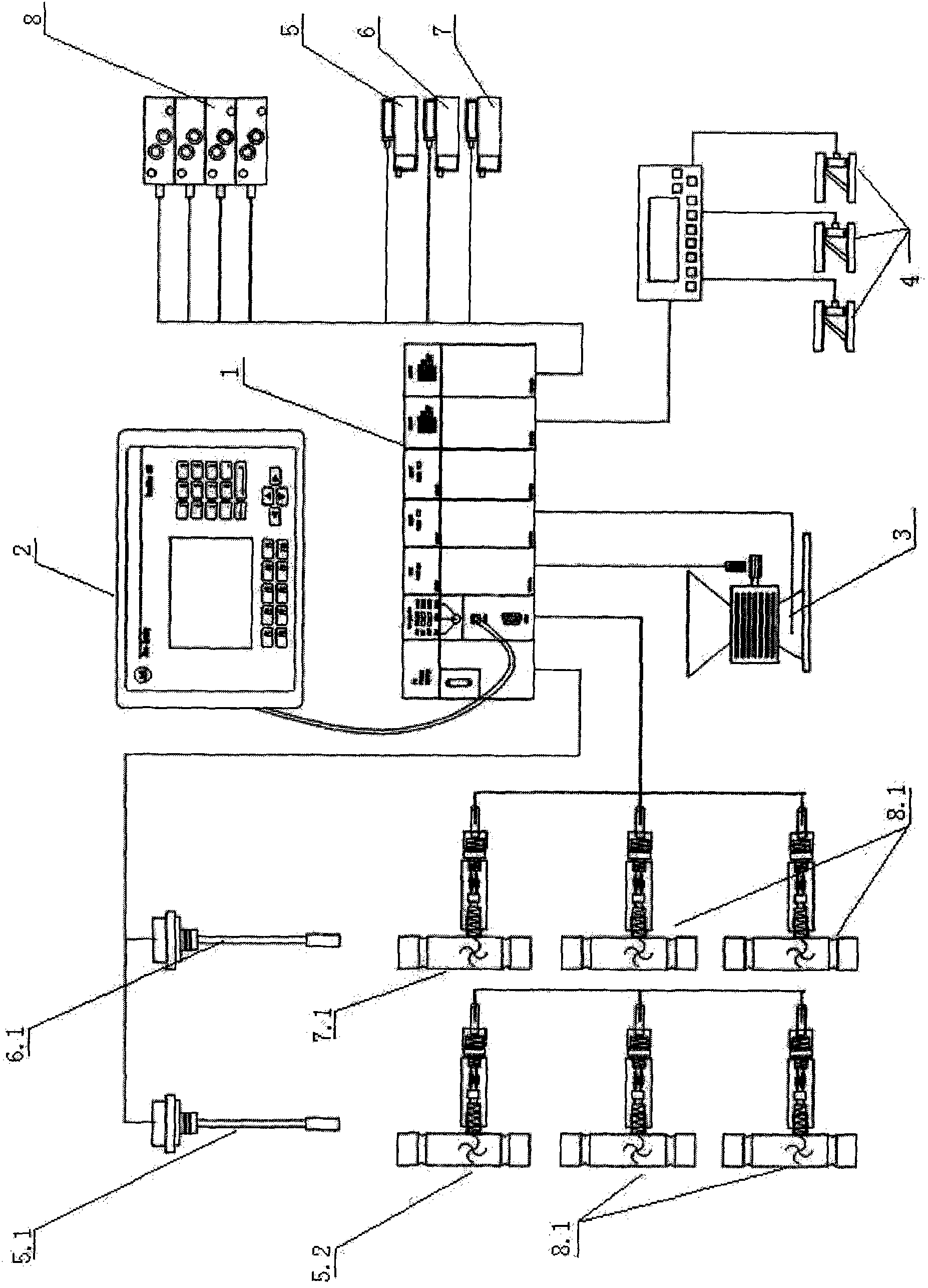

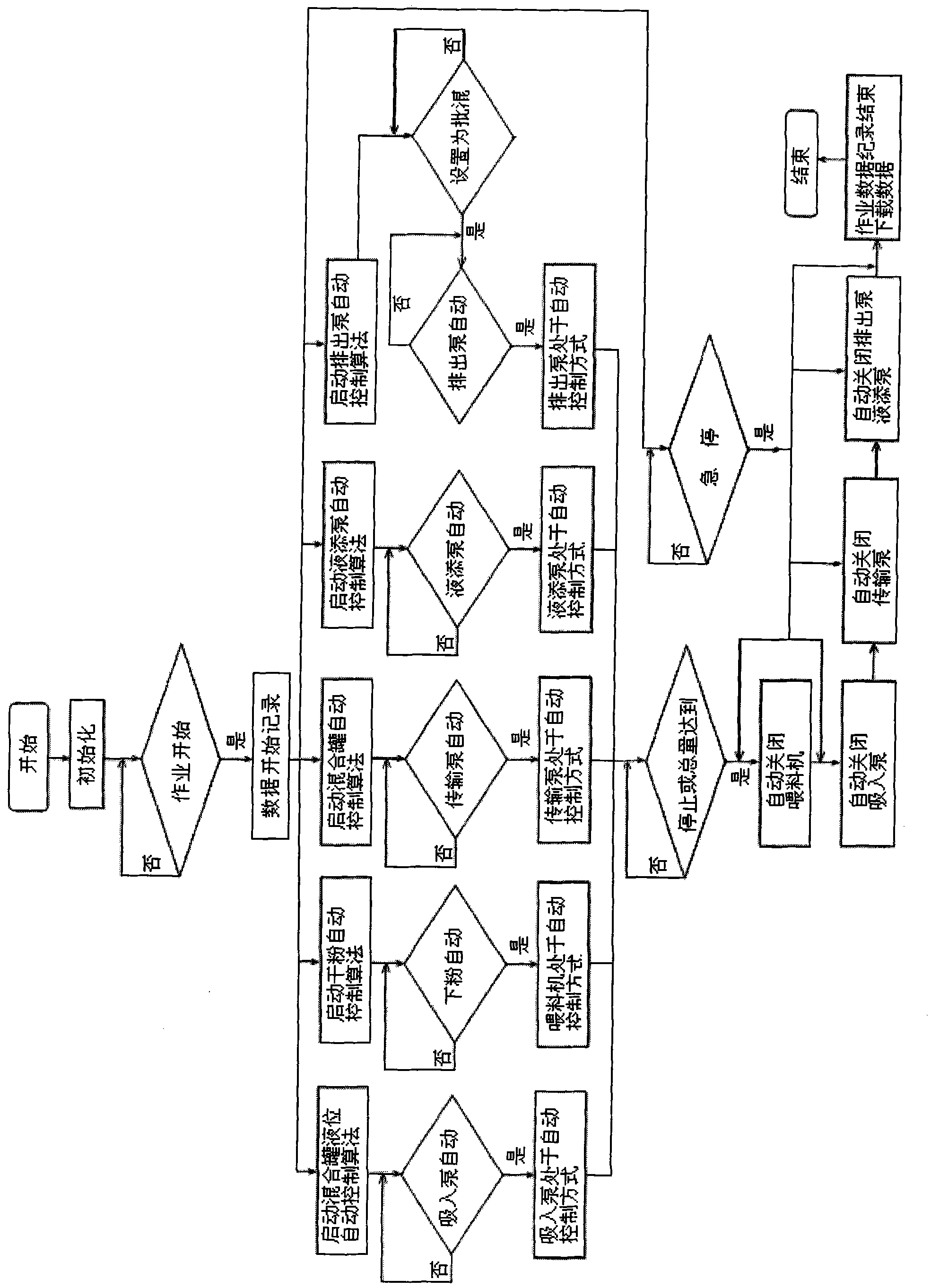

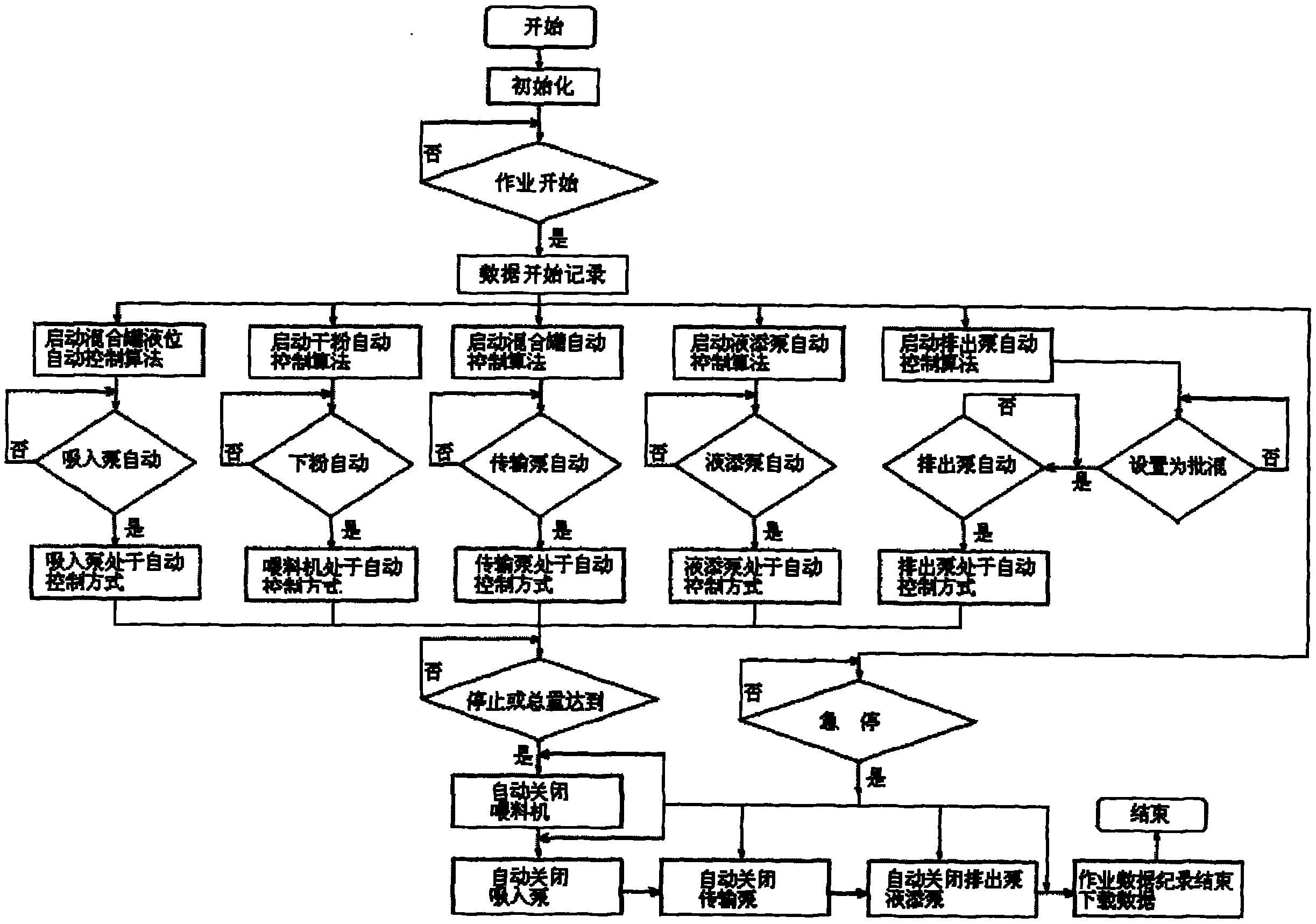

[0034] The working principle of the automatic mixing control system for oil field fracturing fluid is as follows: the dry powder in the dry powder tank is lowered into the dry powder funnel through the screw feeder, and the injector generates negative pressure to pump the dry powder into the high-energy constant pressure mixer and the high-speed injection water for mixing. The flow of clean water and the amount of dry powder can be adjusted by the clean water suction pump (referred to as the suction pump) and the screw feeder (referred to as the feeder), and the flow rate of the liquid addition is controlled by the liquid addition pump. In the mixing tank, the clear water and dry powder are initially swollen and hydrated, and the mixed liquid in the mixing tank is pumped into the hydration tank through the transfer pump at the bottom of the mixing tank. After final swelling and hydration in the hydration tank, the mixed mixture and liquid additives are discharged to the discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com