Method and device for controlling the condensator coolant water of a vapour stream vacuum pump

A technology of jet vacuum pump and condenser, which is applied in the direction of pump device, jet pump, pump control, etc., can solve problems such as cavitation, unsatisfactory, and increase in pump failure, so as to avoid water shortage and avoid cavitation The effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

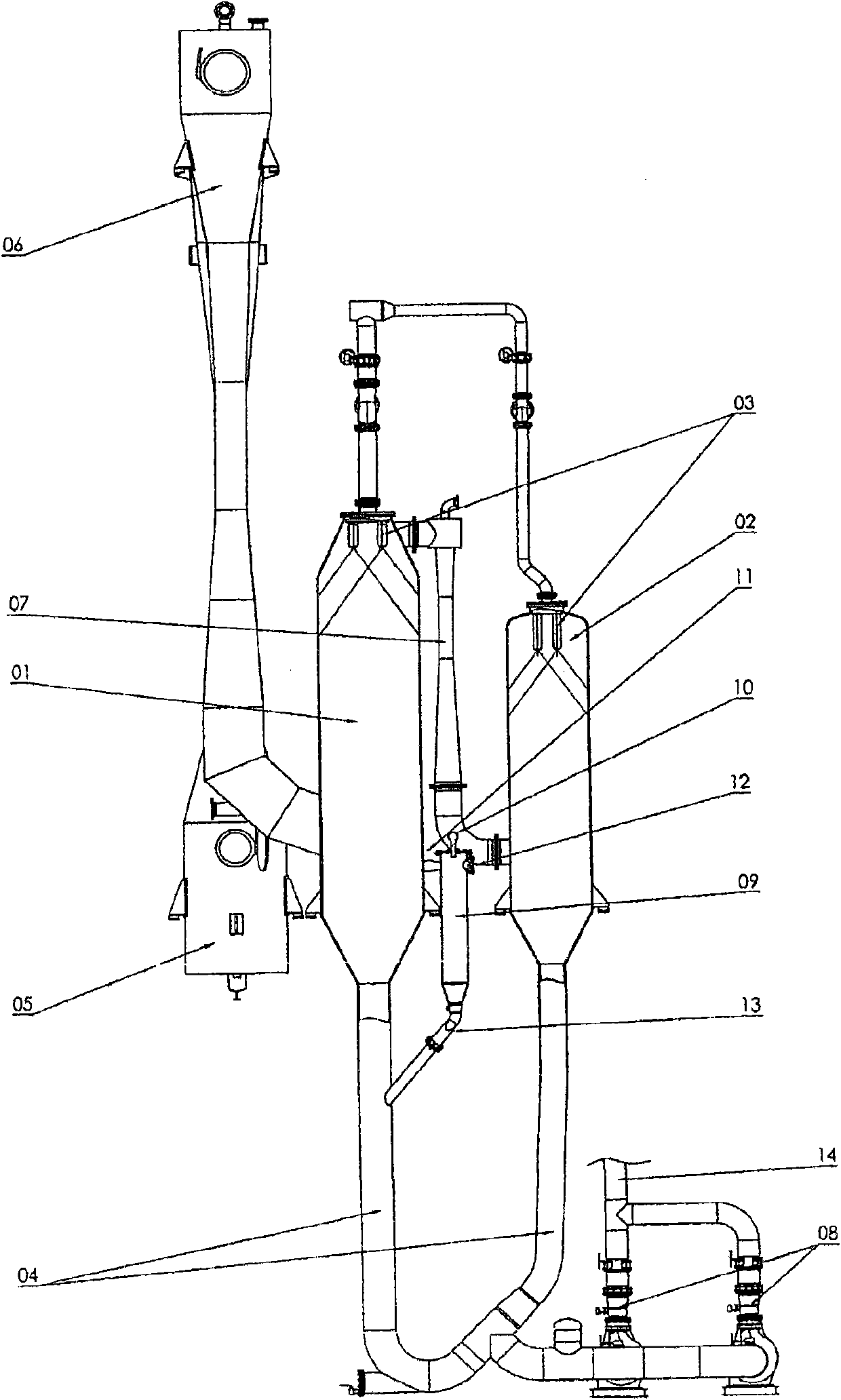

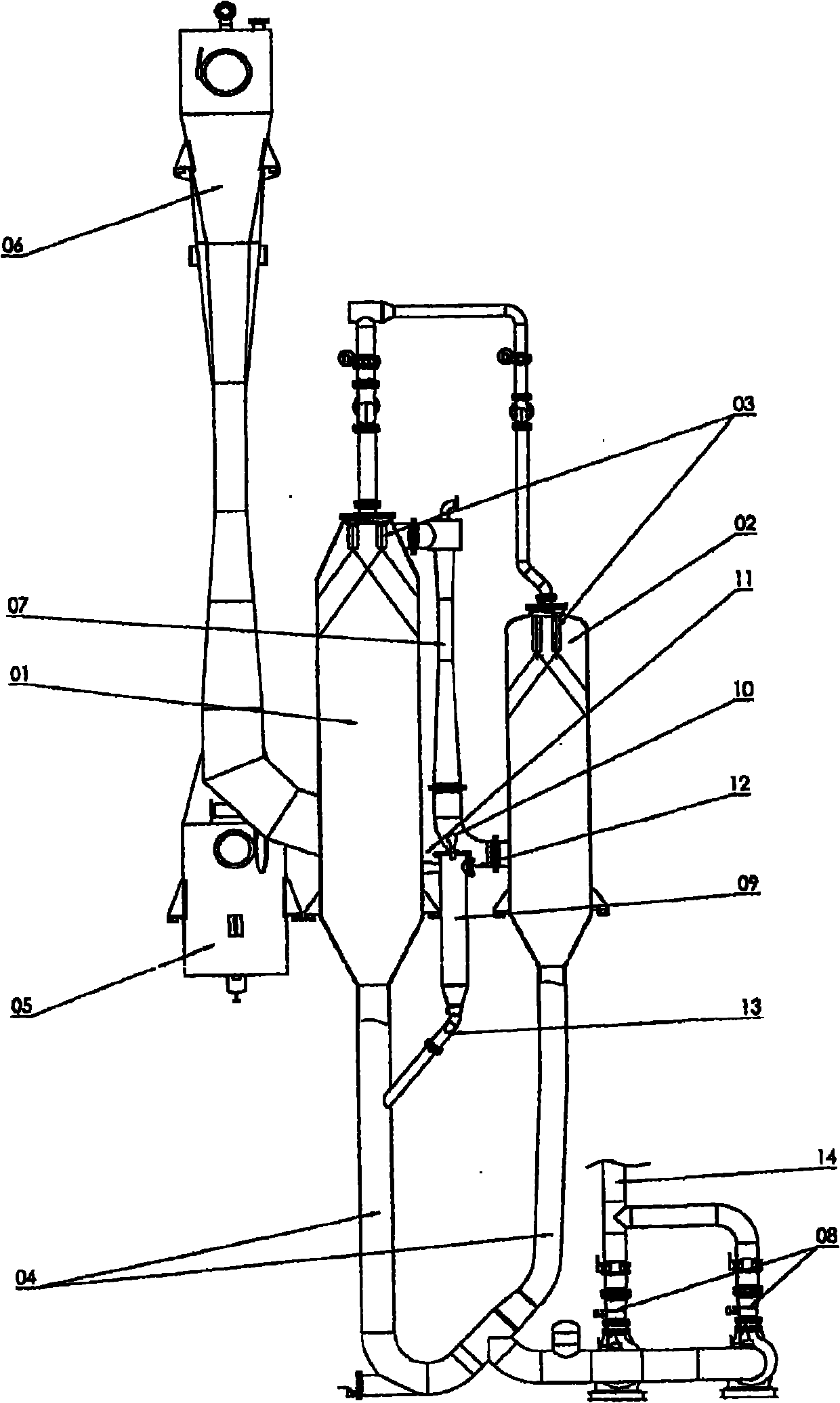

[0022] figure 1 The shown vacuum pump station includes: condensers 1, 2 with cooling water nozzles 3; steam ejectors 5, 6, 7; external liquid level measuring bottle 9, measuring probe 10 and extension Condenser cooling water pump 8 to pressure equalizing pipe 11 of condenser 1 ; and inclined discharge pipe 13 extending into condensate downflow pipe 4 of condenser 1 . The condenser cooling water pump 8 delivers the cooling water through a return line 14 for further treatment of the cooling water, such as a carbon monoxide scrubber (CO washer), a settling tank, etc. not shown here.

[0023] According to the invention, the condensers (1, 2) are measured in a measuring bottle (9) configured to communicate with the vessel and arranged outside the condenser by means of a measuring method suitable for vacuum operation, such as a radar or laser probe (10). level of the cooling water and use the measured value as the controlled variable and signal for the speed-controlled cooling wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com