Double-impeller serial pump with cone-shaped hubs

A conical wheel and double impeller technology, which is applied to components, pumps, pump elements, etc. of pumping devices used for elastic fluids, can solve the problem of not meeting the requirements for the use of water jet propulsion systems and the difficulty of space layout of two-stage axial flow pumps , axial dimension extension and other issues, to achieve the effect of compact structure, improved cavitation performance, reduced size and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings.

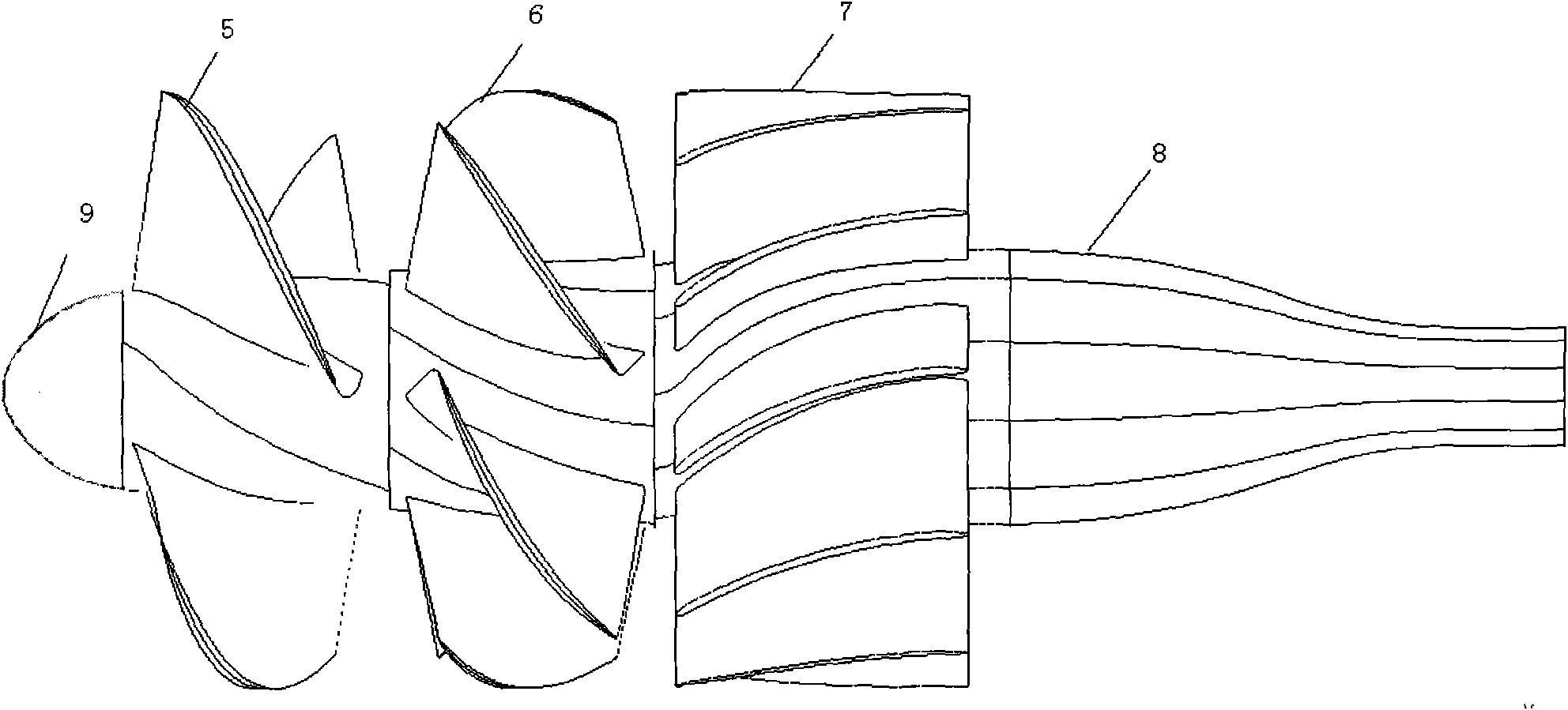

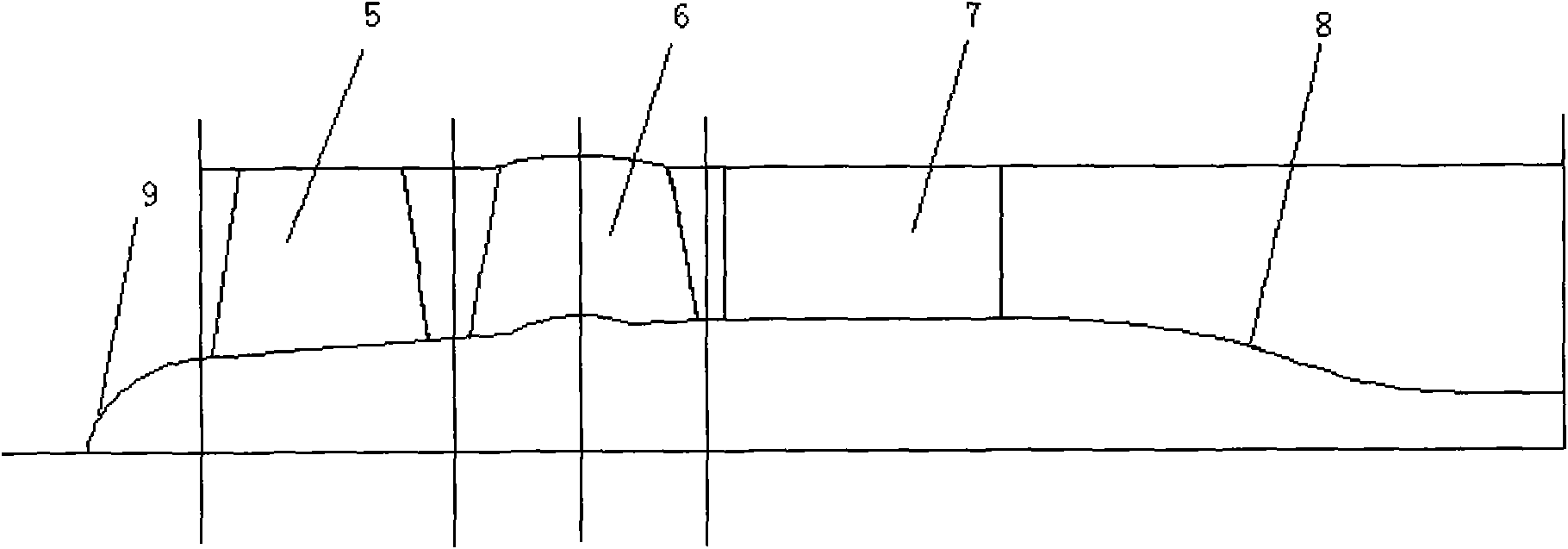

[0022] figure 2 It is the overall structure diagram of the double-impeller tandem pump with conical hub realized according to the present invention, which consists of the following five parts, 5 is the primary impeller, 6 is the secondary impeller, 7 is the guide vane, and 8 is the conical diffuser pipe , 9 is the water guiding cone. It can be seen from the figure that the number of blades of the primary impeller is 3, the number of blades of the secondary impeller is 6, the number of blades of the guide vane is 11, and the hub ratio of the primary impeller and secondary impeller is variable.

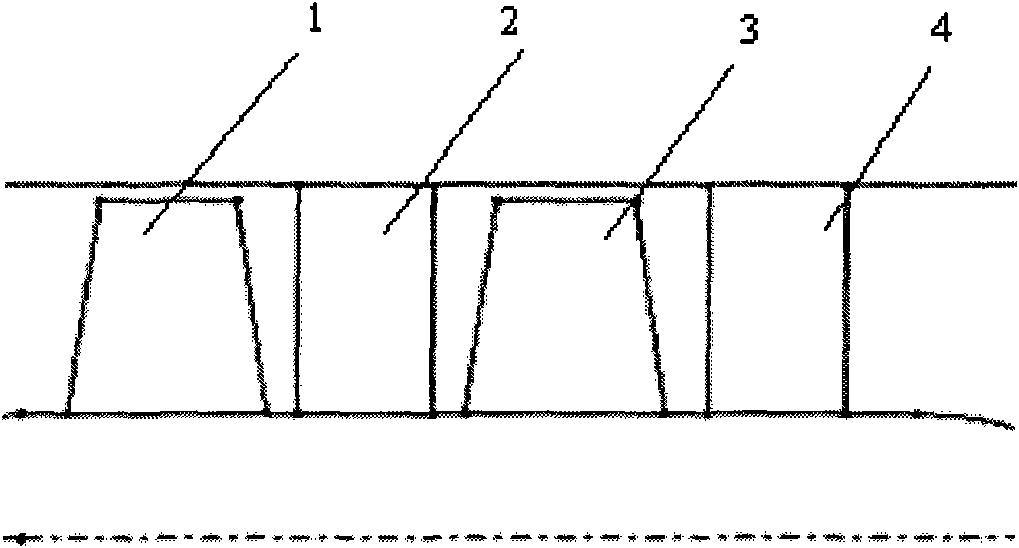

[0023] image 3 It is the hub diagram of the double impeller tandem pump. It can be seen from the figure that the impeller hub is a conical variable hub ratio design. The placement angle of the primary impeller is not adjustable, and the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com