Deashing method of rotary tube bundle heat exchanger

A heat exchanger and rotary technology, applied in the field of heat exchange, can solve the problems of heavy maintenance workload, complex soot blowing system, incomplete soot cleaning, etc., so as to reduce the cost of soot cleaning, avoid stuck phenomenon, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

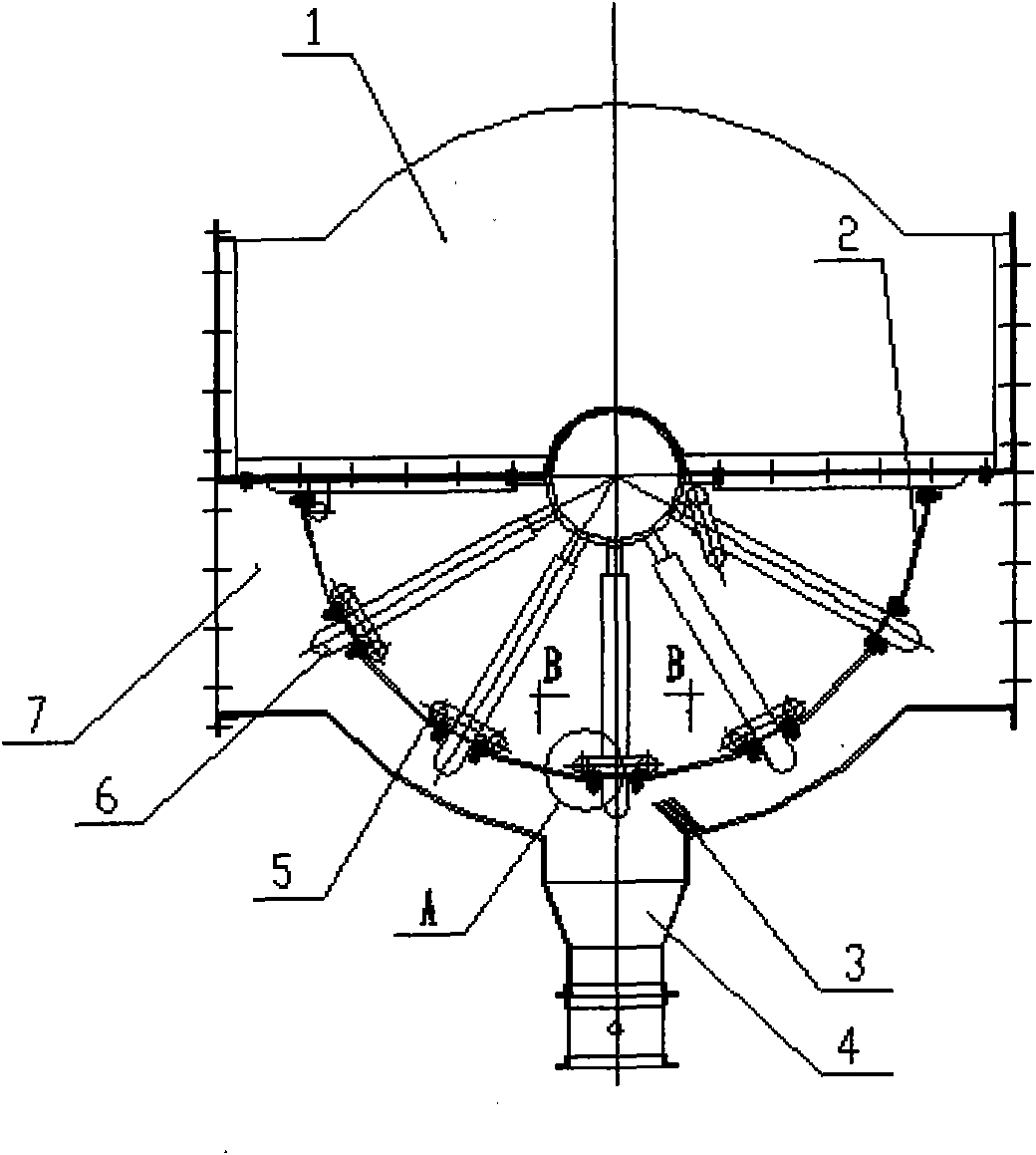

[0015] In conjunction with accompanying drawing, provide embodiment of the present invention as follows:

[0016] Such as figure 1 As shown: the upper outer cover 1 and the lower outer cover 7 of a rotary tube bundle heat exchanger are bounded by the rotation axis of the heat exchanger, and are divided into upper and lower detachable parts, which can be connected to the outside by flange or welding. Each set of ∪-type heat exchange tube bundles 6 of the heat exchanger is covered with a dust cleaner that can slide up and down along it. The bottom of the lower cover 7 is provided with a dust hopper 4 communicating with it for regular removal of dust. A bottom steel wire brush 3 is installed on the edge of the connection between the bottom of the lower outer cover and the dust hopper to remove the dust accumulated in the horizontal direction of the outermost heat exchange tube bundle.

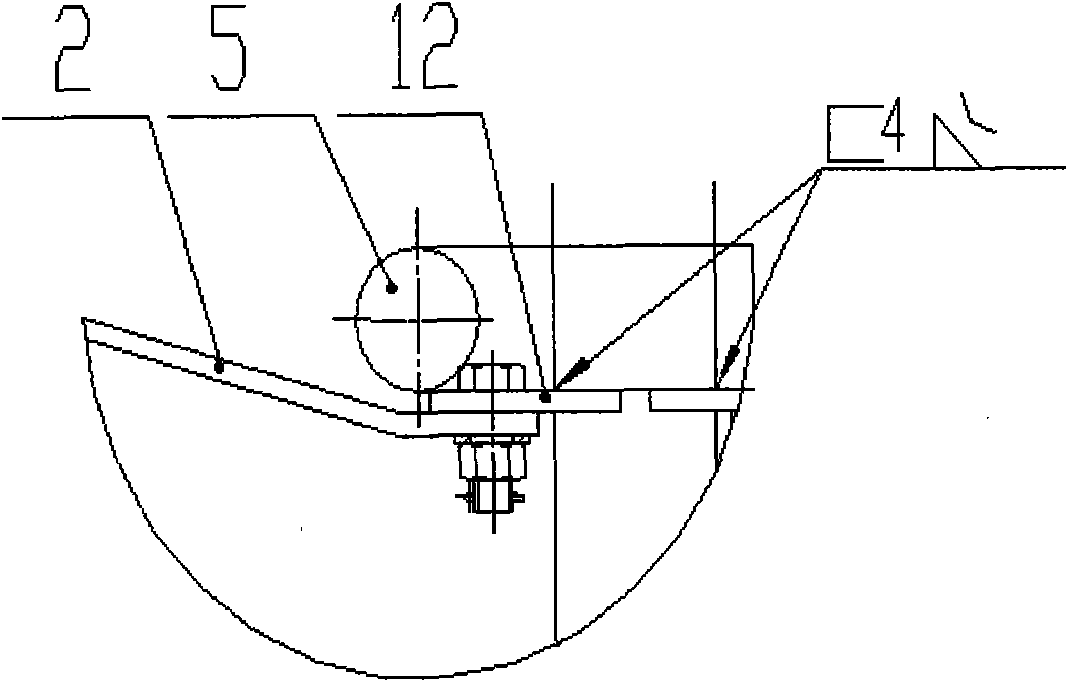

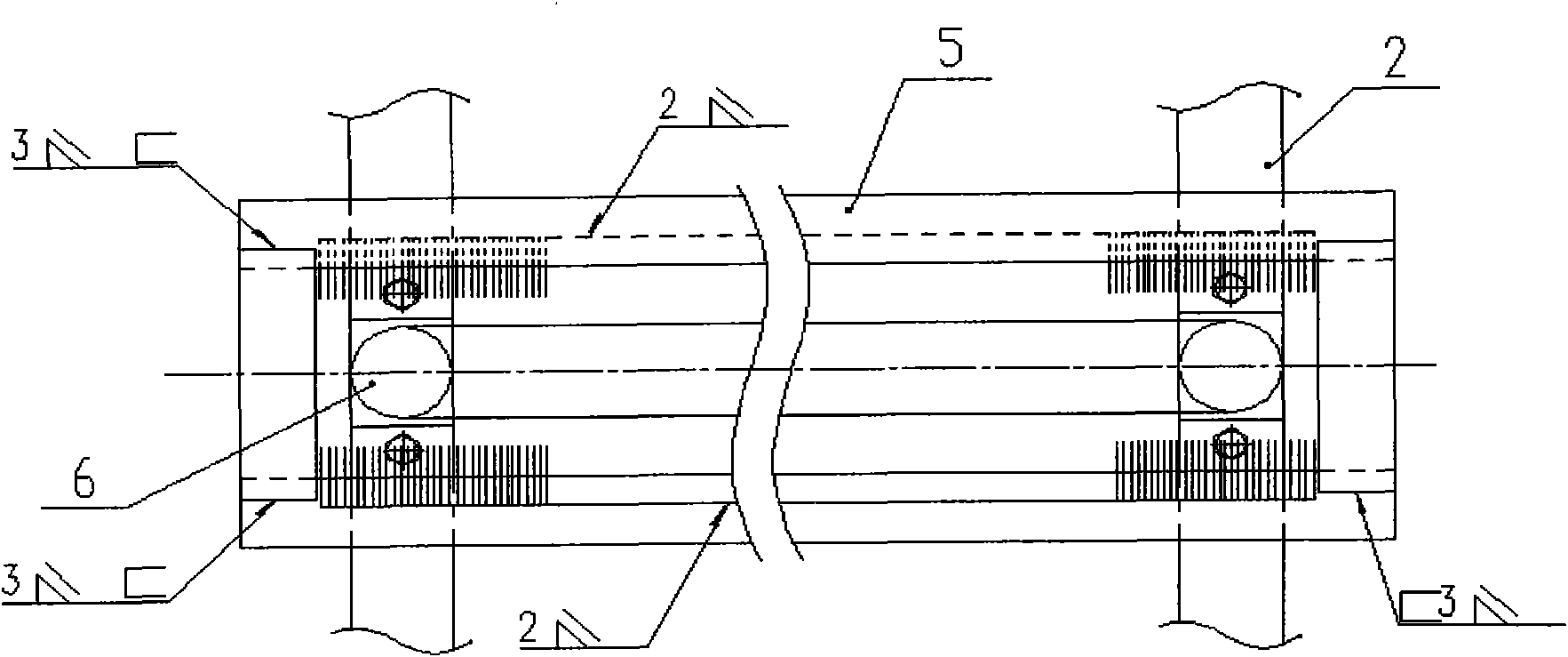

[0017] Such as figure 2 , 3 As shown: a soot cleaner 5 is set on each group of ∪-type hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com