Test jack horse and test method of electric vehicle electromagnetic and frictional brake integrated system

A technology of friction braking and electric vehicles, which is applied in the direction of vehicle testing, automobile tire testing, machine/structural component testing, etc. It can solve problems that do not involve the test bench of the integrated system of automobile electromagnetic braking and friction braking, etc. To achieve the effect of improving the coefficient of friction that cannot be adjusted or adjusted inaccurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

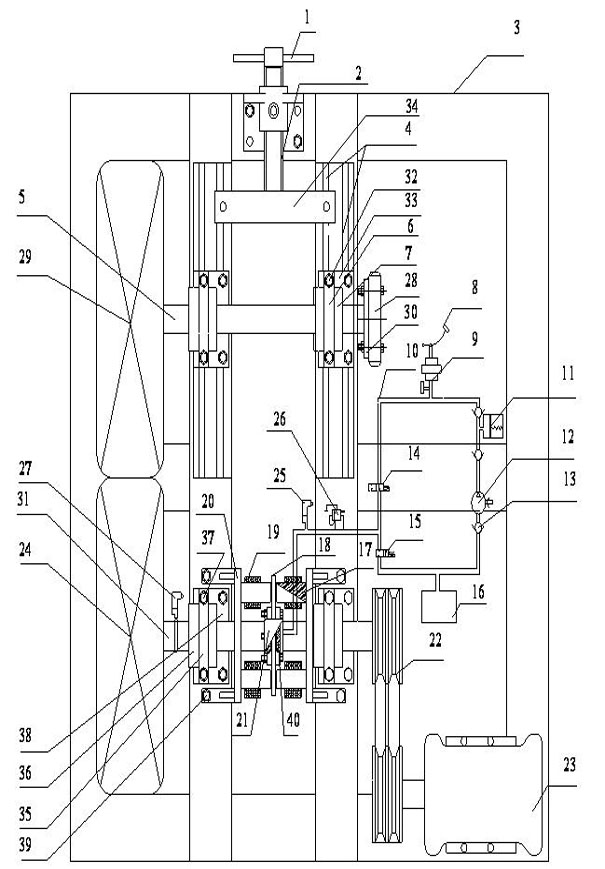

[0019] Such as figure 1 As shown, the test tire 24 is tightly connected with one end of the test tire transmission shaft 31, the other end of the test tire transmission shaft 31 is firmly connected with one end of the pulley device 22, and the other end of the pulley device 22 is connected with the drive motor 23. After the drive motor 23 starts, the power will be transmitted according to: drive motor 23→belt pulley device 22→test tire transmission shaft 31→test tire 24, so that the test tire 24 is rotated, and the drive motor 23 rotating speed can be adjusted by the motor speed regulating circuit to This simulates the wheel speed of the car while it is moving.

[0020] The test tire 24 is in contact with the load tire 29, the load tire 29 is tightly connected to one end of the load wheel drive shaft 5, and the other end of the load wheel drive shaft 5 is connected to the flange 30, and the flange 30 is connected to the rotating flywheel 28 through fastening bolts. connect. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com