Two-side exposure device

An exposure device and surface exposure technology are applied in photolithography exposure devices, microlithography exposure equipment, optics, etc., which can solve the problems of reduced production capacity, time-consuming mask replacement, and difficulty in exposing multiple masks, so as to prevent Reduced productivity and reduced processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

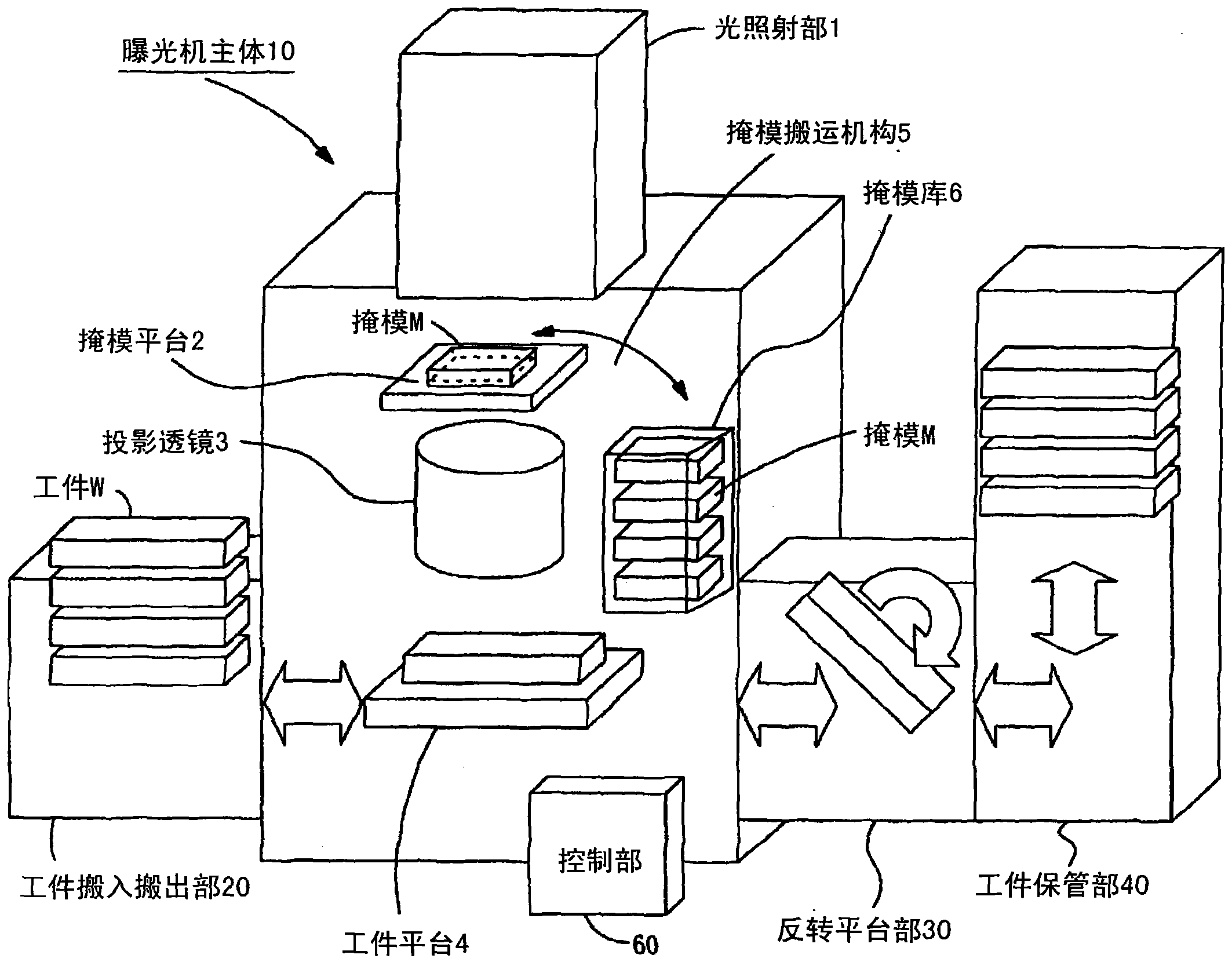

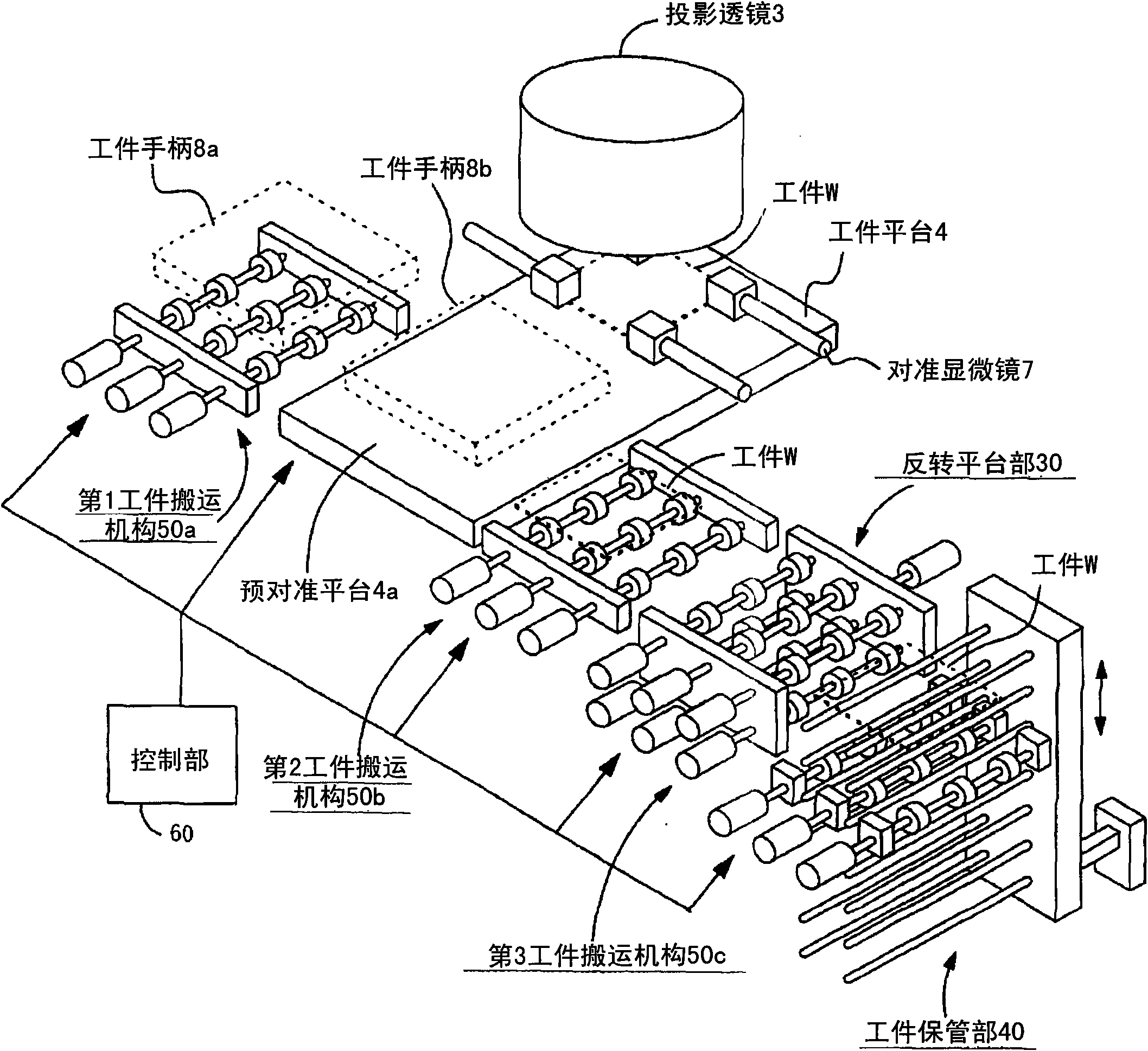

[0080] figure 1 It is a figure which shows the schematic structure of the double-sided exposure apparatus of the Example of this invention.

[0081] The double-side exposure apparatus of this embodiment is roughly divided into an exposure machine main body 10 , a workpiece loading and unloading unit 20 , an inversion table unit 30 , and a workpiece storage unit 40 .

[0082] In addition, the exposure machine main body 10 includes: a light irradiation unit 1 that emits exposure light; a mask stage 2 on which a mask M on which a pattern (mask pattern) such as a circuit formed on a workpiece is formed; A workpiece stage 4 for exposing the workpiece W; a projection lens 3 for projecting a mask pattern on the workpiece W on the workpiece stage 4; a mask library 6 for storing a plurality of masks; and the like.

[0083] In addition, the exposure machine main body 10 includes: a moving mechanism for the mask stage 2; a moving mechanism for the workpiece stage 4; an alignment micros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com