Starting valve control type lead acid storage battery with pure water chambers

A technology of lead-acid batteries and pure water chambers, which is applied in the direction of lead-acid batteries, lead-acid battery construction, battery pack components, etc. It can solve the problems of poor impact resistance, reduced production efficiency, long running time, etc., and achieves hot melting Good performance and impact resistance, ensuring deep cycle service life and long deep cycle service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

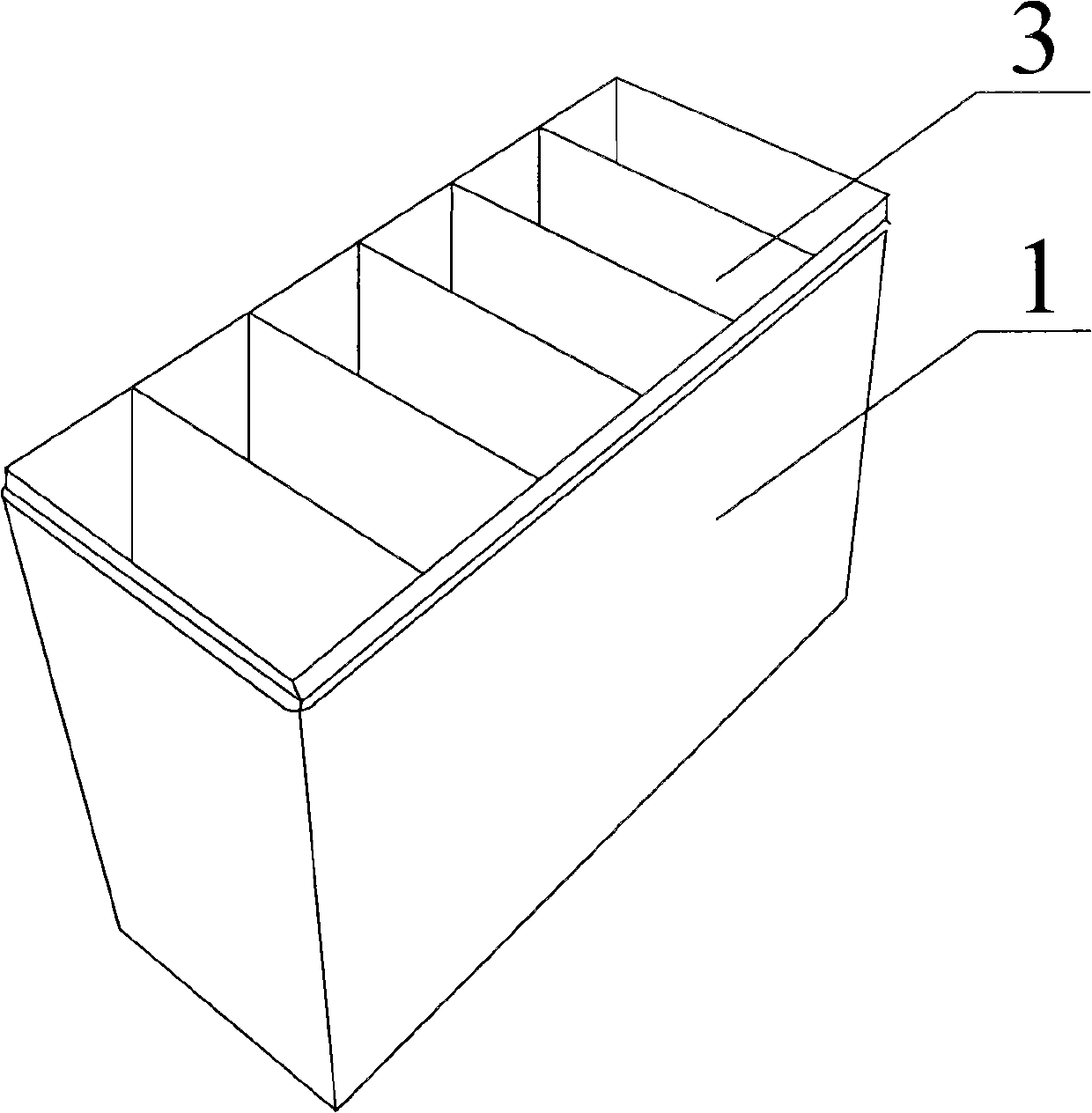

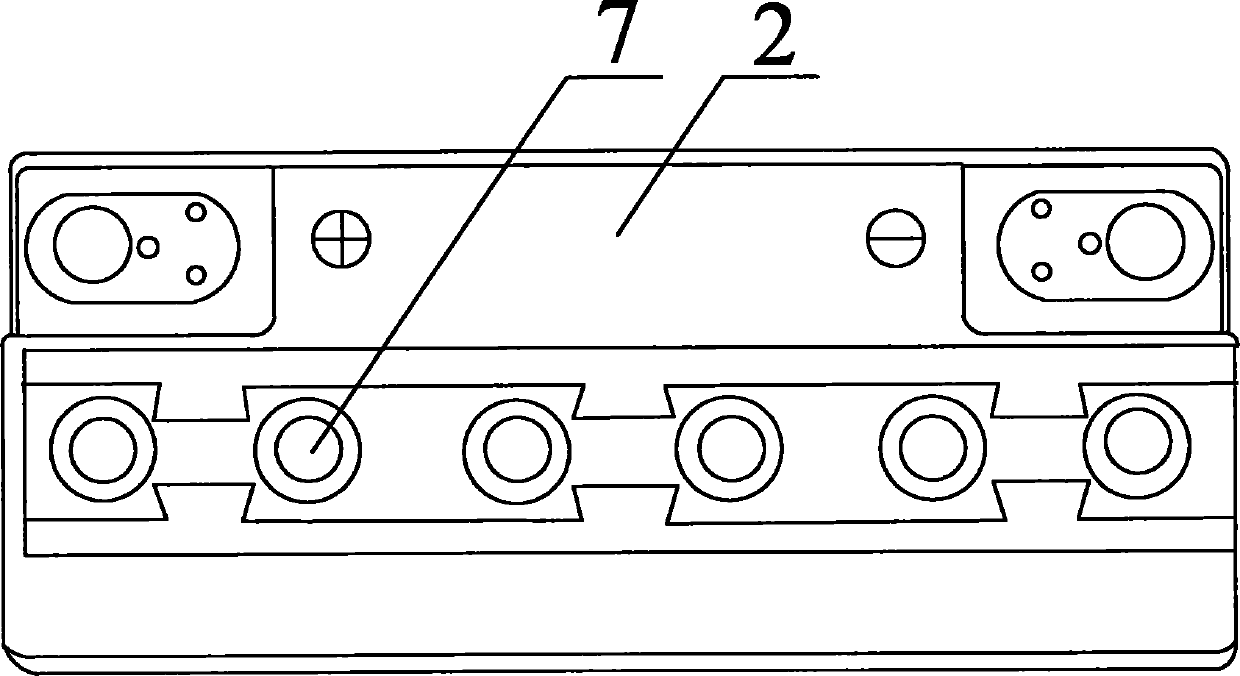

[0038] Such as Figure 1-8 As shown, the valve-regulated lead-acid battery with the pure water chamber 5 is mainly composed of a battery tank 1 divided into twelve cells by an intermediate wall 3, and a battery cover 2 matching the battery tank 1. The battery tank 1, the middle wall 3 and the battery cover 2 are all made of PP plastic material.

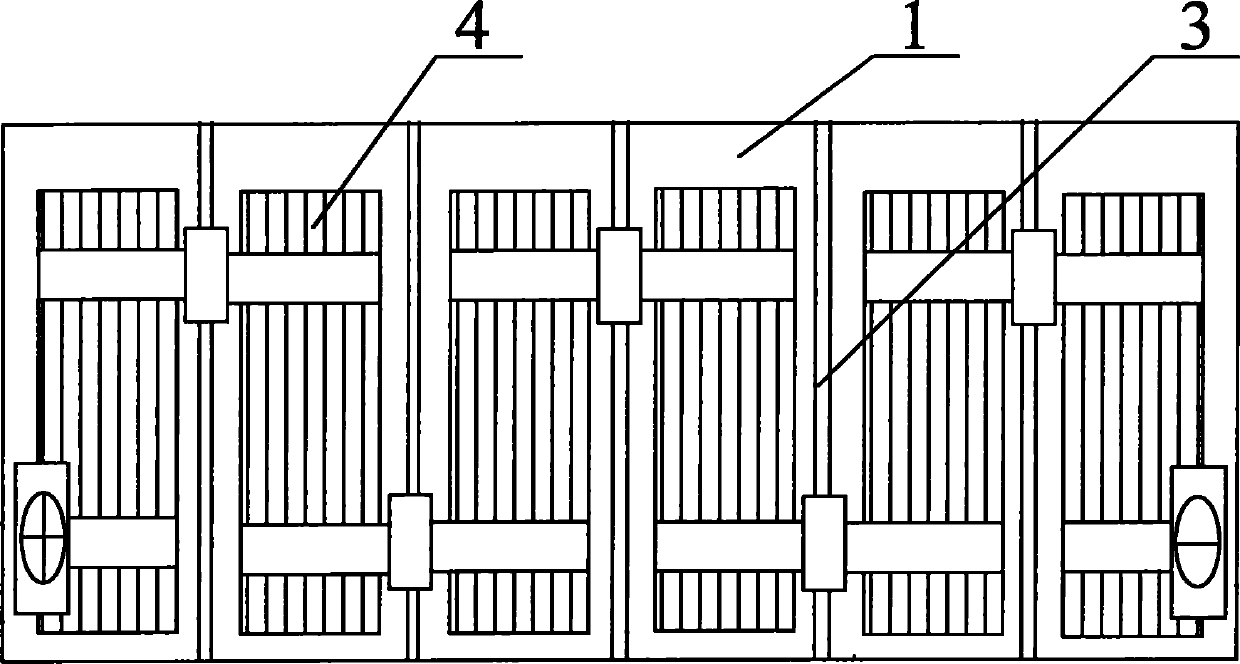

[0039] Such as Figure 4 As shown, the single-cell battery tank 1 is distributed in two rows, one of which is the electrode group chamber 12, and the electrode group 4 is placed in the electrode group chamber 12 and filled with electrolyte, and the other row is the pure water chamber 5 Each pole group 4 corresponds to a pure water chamber 5, and a communication conduit 6 is provided between the pole group 4 and the corresponding pure water chamber 5, and the communication conduit 6 extends to the bottom of the pure water chamber 5. Such as Figure 8 As shown, in the lower section of the intermediate wall 3 between the pole group ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com