Pluggable sliding contact line system

A sliding contact line and plug-in technology, which is applied in the direction of connection, clamping/spring connection, collector, etc., can solve the problems of insufficient tightness and smoothness of meshing, troublesome installation, low impedance of copper conductors, etc., to save installation time, Effects of increased ampacity and low impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

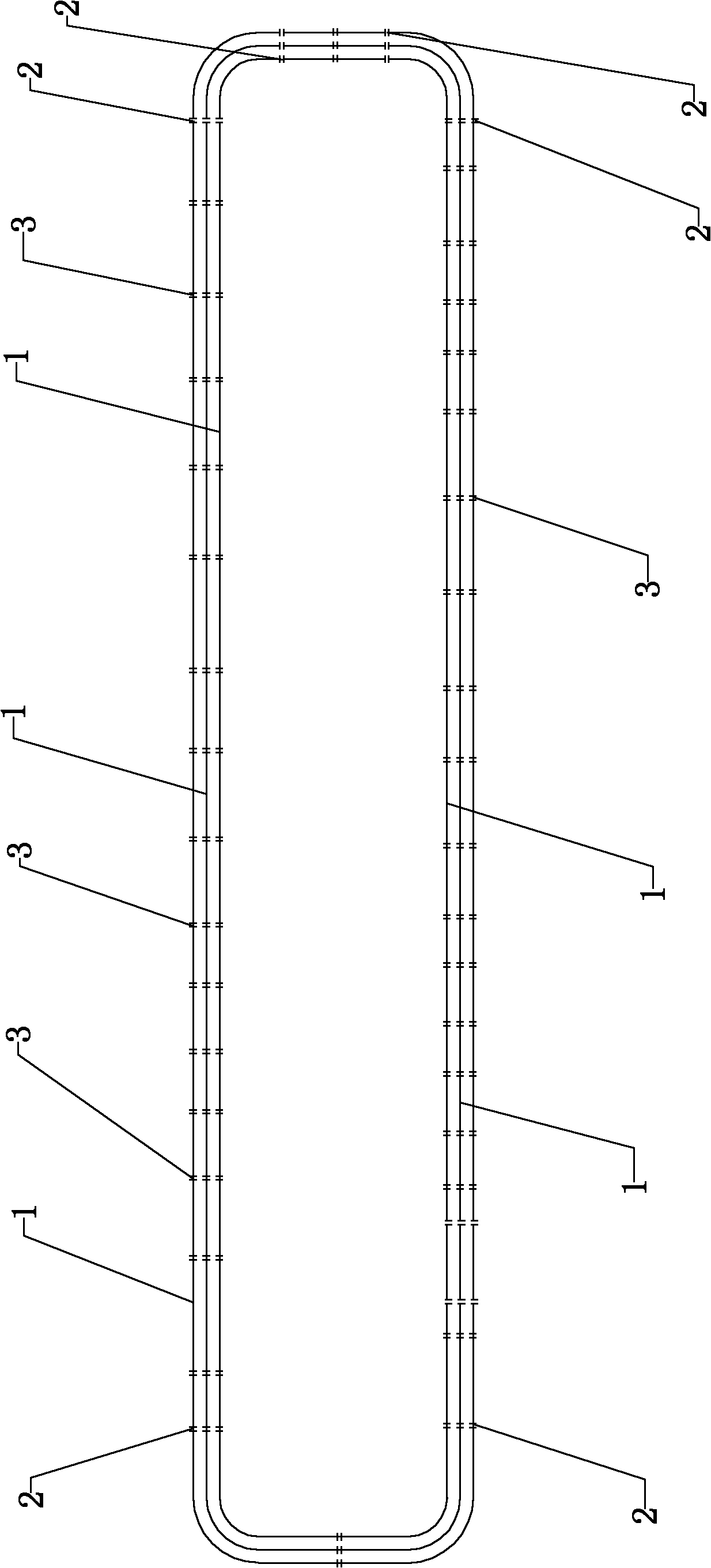

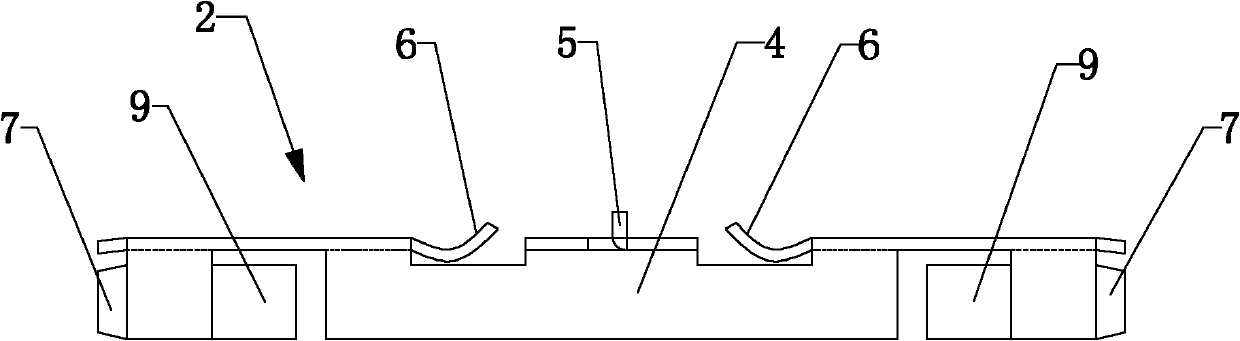

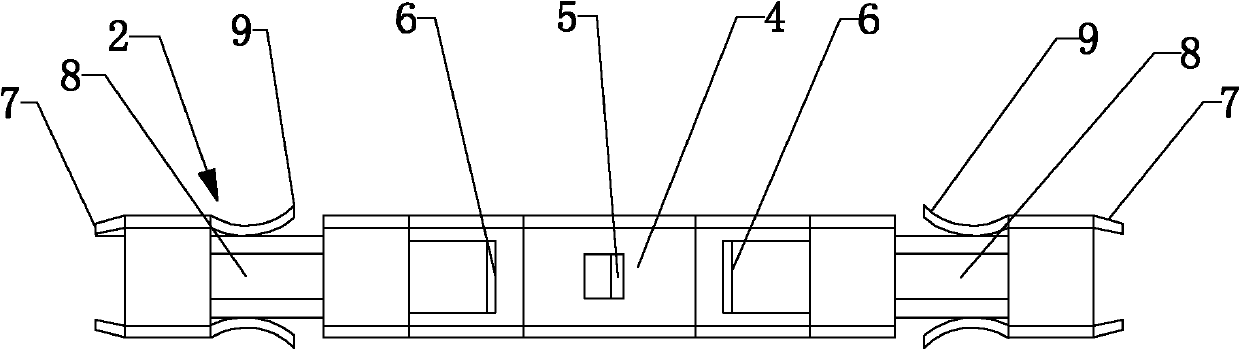

[0018] Such as Figure 1-7 As shown, a plug-in trolley line system according to the embodiment of the present invention includes several trolley lines 1 connected in sequence to form a track, wherein the segment trolley line 1 located in a straight line and its adjacent trolley line 1 are connected by an external snap-in joint 3, and the trolley line 1 at the turning and its adjacent trolley line 1 are connected by a built-in joint 2; the built-in joint 2 includes a U-shaped joint body 4, U The middle part of the top surface of the U-shaped joint main body 4 is provided with a center limit card 5, and both sides of the center limit card 5 are respectively provided with an adjustment and fixing card 6, and the two ends of the U-shaped joint main body 4 are provided with a starting card 7, and the U-shaped The top surface of the joint main body 4 and the two sides close to the entry card 7 are respectively provided with an adjustment groove 8 and a limit fixing card 9, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com