Protective film and manufacturing method for same

A manufacturing method and technology of protective film, which are applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of migration of antistatic agents, poor products, and dirt, and achieve good antistatic properties, The effect of preventing whitening and good smoothness

Active Publication Date: 2011-04-06

YOULCHON CHEM

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] First, during transportation, scratches are generated on the surface due to the lack of smoothness between the protective film and the object to be protected, that is, the adhesive material, that is, the so-called pol-dirty phenomenon occurs, resulting in product failure

[0006] In addition, wrinkling occurs when additives such as slip agents are inserted, and migration of the antistatic agent occurs when the humidity rises when the antistatic agent is added, resulting in poor sliding and scratches

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

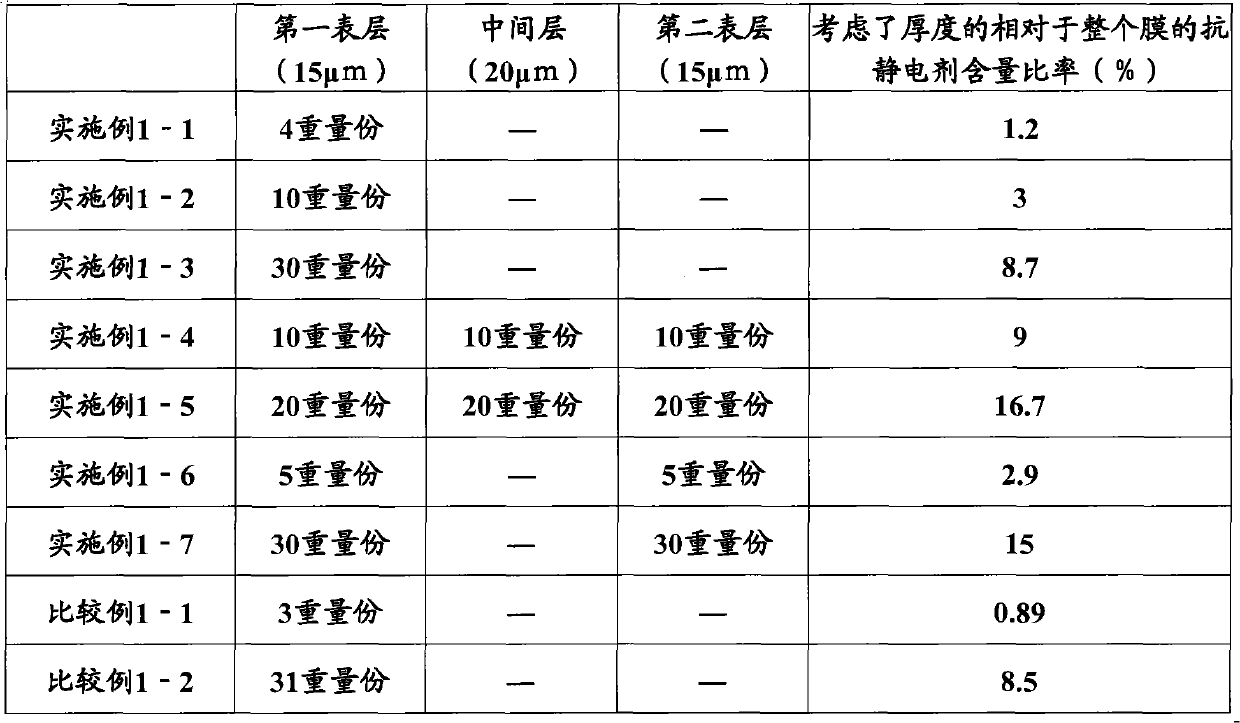

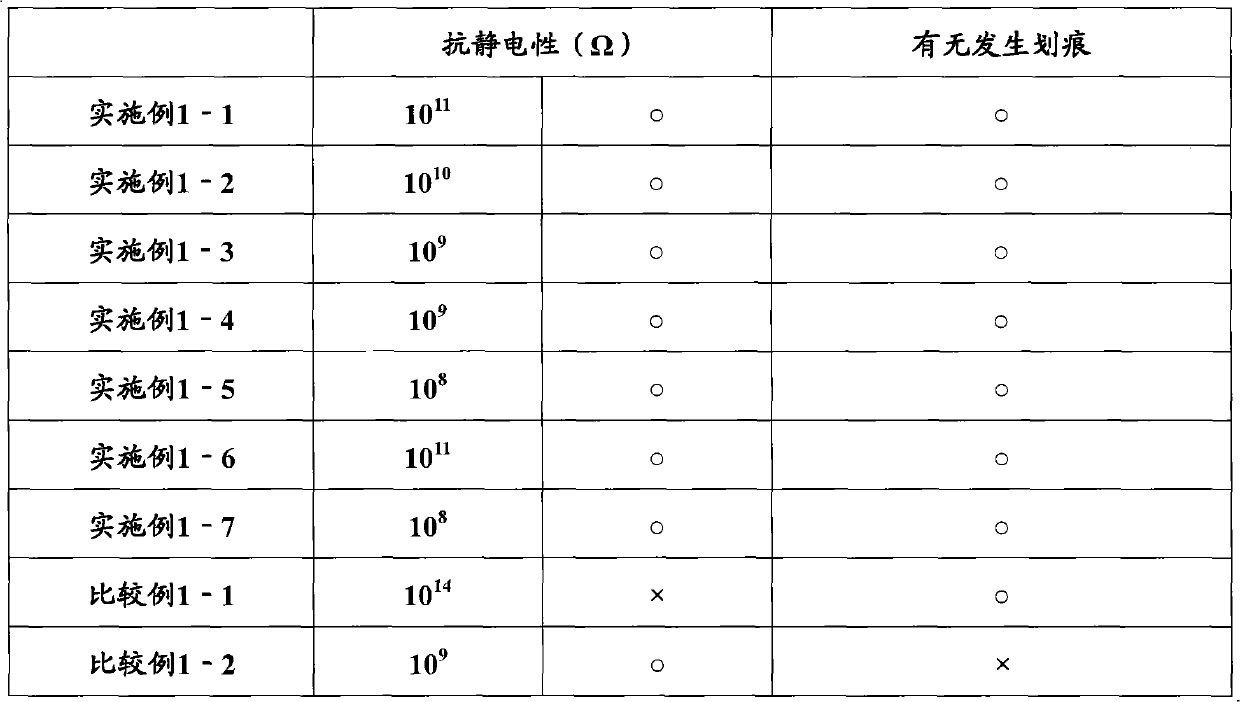

Embodiment 1

[0070] Example 1: Consisting of the first membrane only

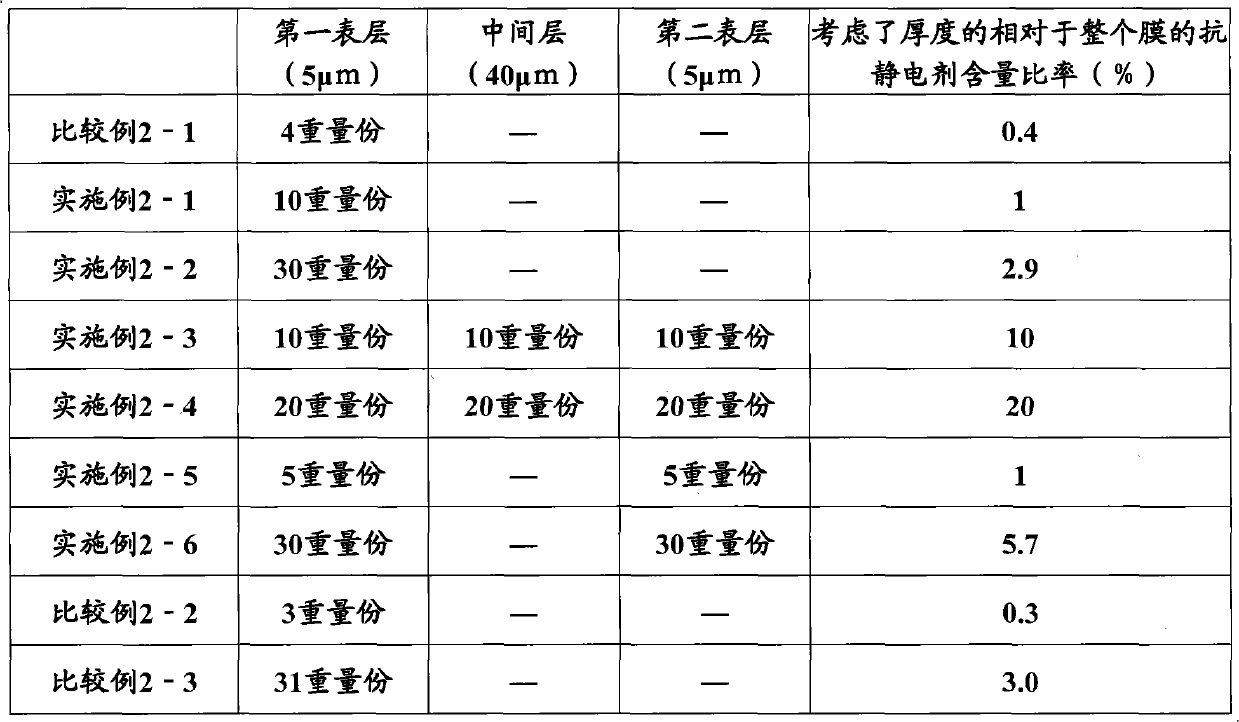

Embodiment 2

[0071] Example 2: Second Film / Adhesive / Third Film

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

Provided are a protective film and a manufacturing method thereof, in which the protective film includes a co-extruded film composed of an intermediate layer, and a first skin layer and a second skin layer present at both sides with the intermediate layer being disposed therebetween, wherein one or more layers of the first skin layer or the second skin layer contain polymer-based antistatic agents consisting of ethylene-based unsaturated carboxylic acids.

Description

technical field [0001] The present invention relates to a protective film and a manufacturing method thereof. Background technique [0002] In various display devices such as liquid crystal display (LCD), cathode ray tube (CRT), plasma display (PDP), etc., or products such as architectural glass materials, it is easy to occur due to product assembly, manufacturing, transportation, Dust and foreign matter caused by static electricity generated during storage, etc., or damage caused by scratches, so a protective film is used to prevent such damage. [0003] As the above-mentioned protective film, there are, for example, a protective film in which an adhesive is applied to a polymer film, a protective film in which a hard coat layer is applied to a polyethylene terephthalate (PET) film, and In these films, additives such as slip agents and antistatic agents are used as protective films. [0004] However, according to the research results of the inventors of the present invent...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B32B27/32

CPCB32B27/00B32B27/18B32B2307/21B32B27/32

Inventor 金永熙姜汉俊韩喜植李相珉

Owner YOULCHON CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com