Hybrid power unit control system

A hybrid power and control system technology, applied in the direction of power devices, hybrid vehicles, pneumatic power devices, etc., can solve the problems of increased weight and increased manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

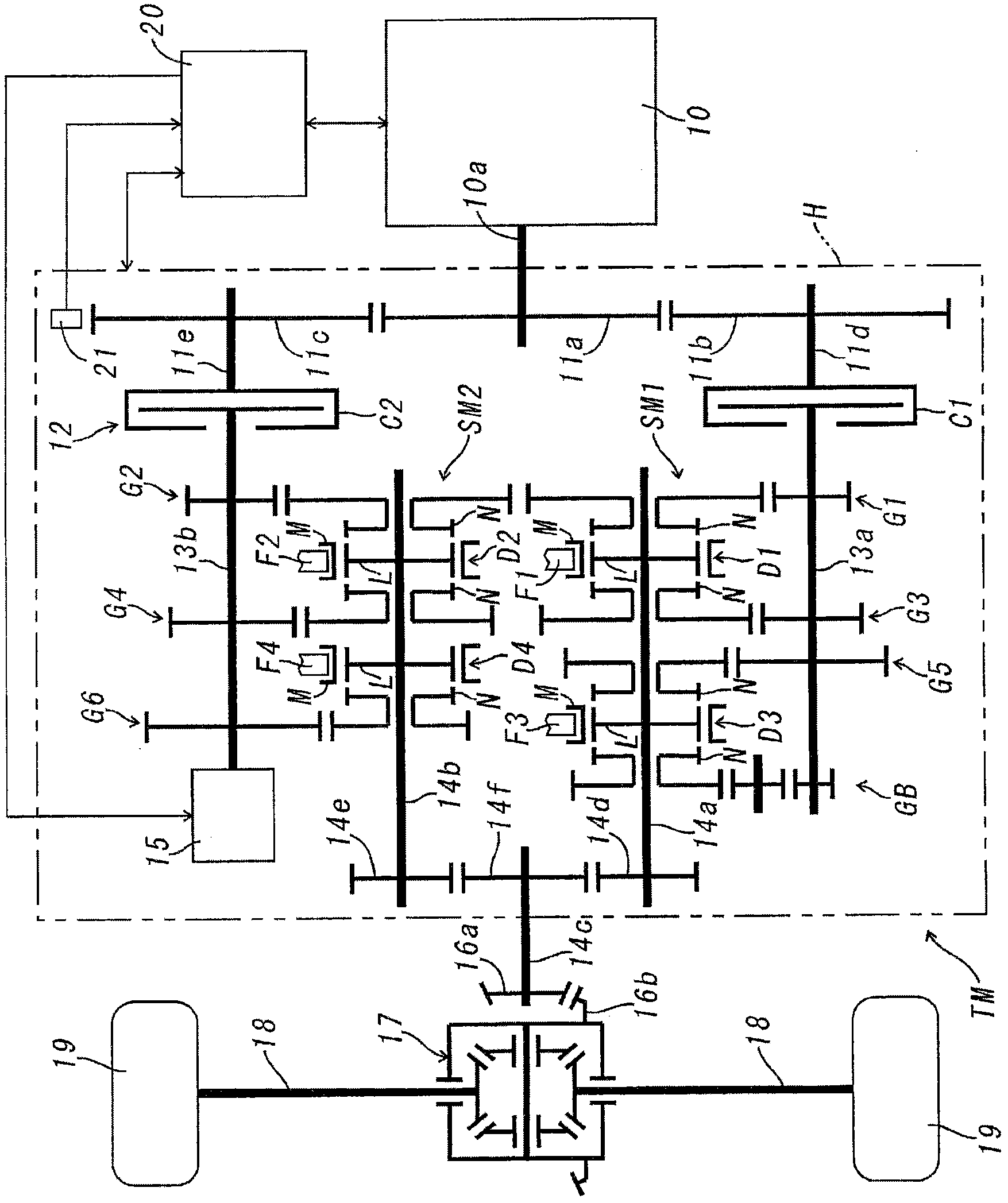

[0018] Below, refer to Figure 1-Figure 4 , the first embodiment of the control system of the hybrid power device of the present invention will be described. In this first embodiment, the hybrid power plant having the control system of the present invention is applied to figure 1 Shown is an automatic transmission TM with 6 forward speeds and 1 reverse speed.

[0019] This automatic transmission TM is a dual-clutch type. In the transmission case H, the first input shaft 13a and the second input shaft 13b, which are arranged in parallel to each other, are supported and can rotate freely, via the first friction clutch C1 and the second friction clutch C2, It is connected to the output shaft 10 a of the engine 10 . The input member of the first friction clutch C1 is coupled to the support shaft 11d of the driven gear 11b, and the drive gear 11a that rotates integrally with the output shaft 10a of the engine 10 meshes with the driven gear 11b. Similarly, the input member of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com