Dry method coating device

A kind of coating and equipment technology, applied in the field of dry coating equipment based on electrostatic fluidized bed, can solve the problems of small coating thickness, particle rebound, affecting coating efficiency, etc., and achieve the effect of safe use and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

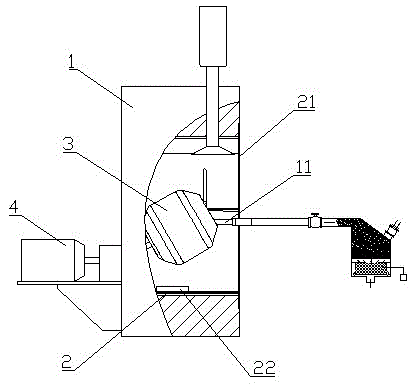

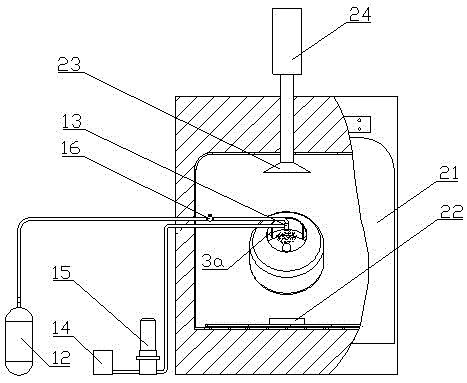

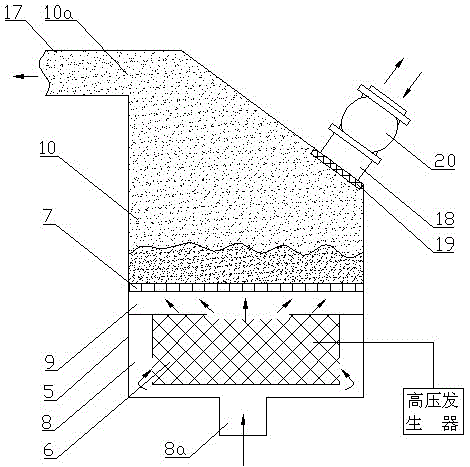

[0022] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 The right side view of the electrostatic fluidized bed is removed from the image 3 It is a structural schematic diagram of an electrostatic fluidized bed, as shown in the figure: the dry coating equipment of this embodiment includes a box body 1, a coating device, an electrostatic fluidized bed and an auxiliary material supply device; the box body 1 is provided with Heat source 2; the coating device includes a cylindrical coating pan 3 with an open end and a coating pan driving assembly 4 for driving the coating pan 3 to rotate around its own axis. In this embodiment, the coating pan driving assembly is The motor and the speed changer are easy to realize, and both are arranged outside the casing, which can avoid dust pollution and damage the motor and the speed changer. The coating pan 3 is arranged in the casing 1, and a rotating shaft is arranged at the bottom thereof, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com