Preparation method of traditional Chinese medicine composition for preventing and treating irregular menstruation

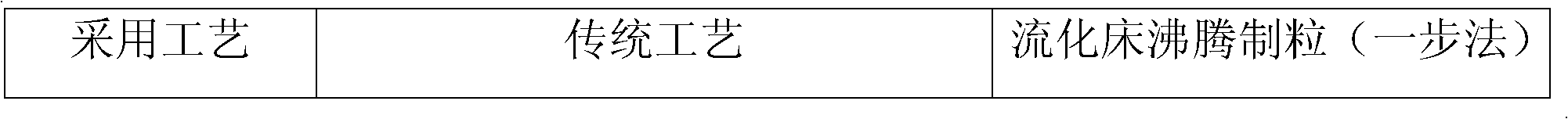

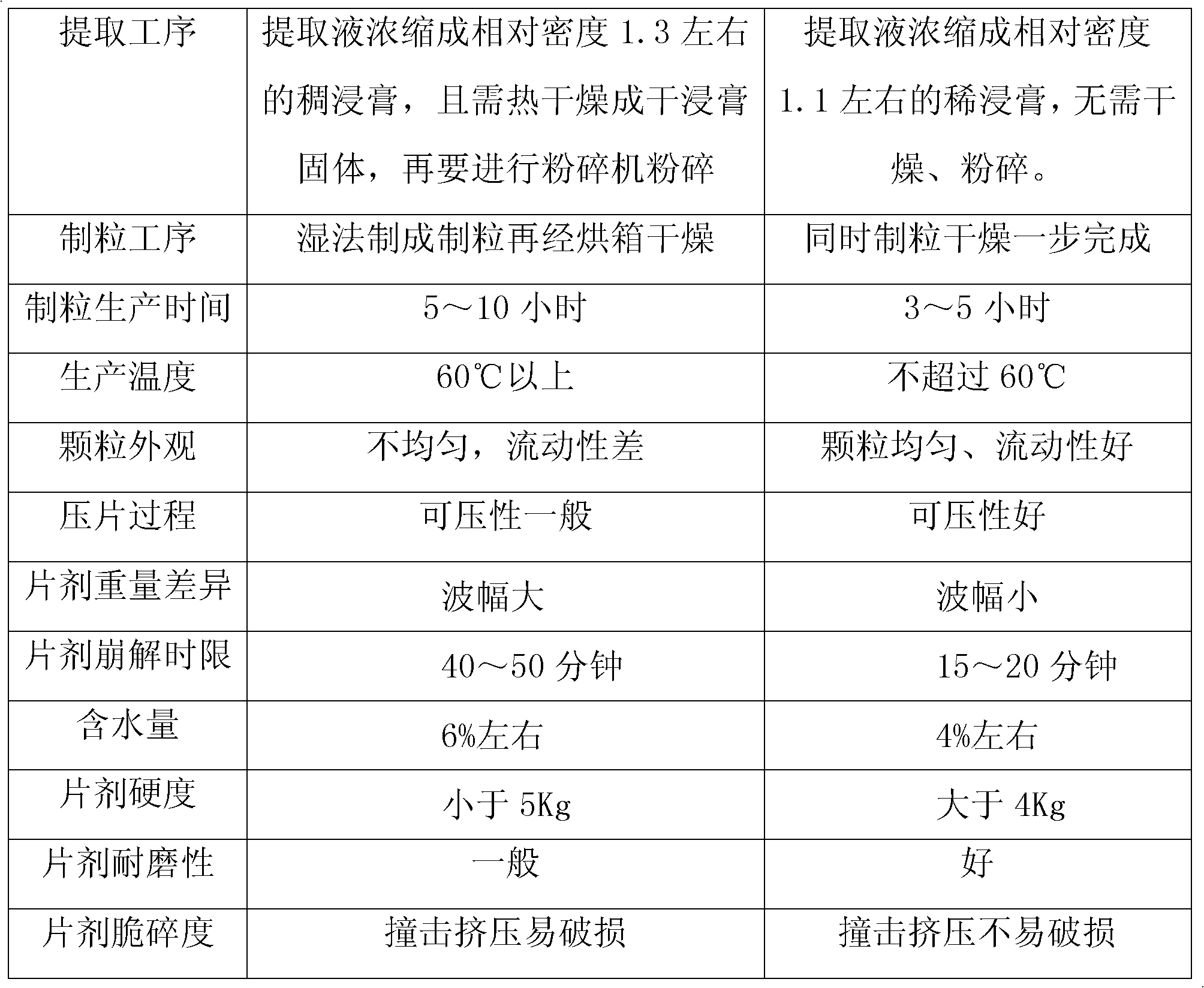

A technology of irregular menstruation and composition, which is applied in the direction of drug combination, pharmaceutical formula, medical preparations containing active ingredients, etc. It can solve the problem of difficulty in uniform particle density and size, difficulty in making tablets with low auxiliary materials, long heating time, etc. problems, to achieve the effect of shortening the concentrated heating time, significant disintegration time, and improved particle size uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Boil 24g of Motherwort, 12g of Rhizoma Cyperi, 12g of Passepartout, 12g of Rhizoma Chuanxiong, 12g of Wangbuliuxing, and 12g of Caulis Spatholobus with water for 2 extractions. The amount of water added for the first extraction is 10 times the amount of medicine, and the extraction time is 2 hours. The amount of water added for the second time is 7 times the amount of medicine, and the extraction time is 2 hours; filter, combine the filtrate, and concentrate into a water-extracted dilute extract with a relative density of 1.05; put dextrin or starch, etc. in a one-step granulator As a substrate, spray the above water-extracted extract as a binder into a one-step granulator, open the air inlet and outlet, control the negative pressure of -0.02MPa to make the powder boil evenly in the granulator tank, and then heat to control the material The temperature is 30°C, one-step granulation is carried out, and the granulation time is 5 hours; the granules produced by the one-step...

Embodiment 2

[0028]Boil motherwort 5g, Cyperus cyperi 5g, Passepartout 5g, Ligusticum chuanxiong 2g, blancia regia 3g, and Caulis Spatholobus 5g with water for 2 extractions. The amount of water added for the first extraction is 6 times the amount of medicine, and the extraction time is 0.5 hour; the second extraction water addition is 4 times of the dose, and the extraction time is 0.5 hour; filter, merge the filtrate, and concentrate into a water-extracted extract with a relative density of 1.18; put dextrin in a one-step granulator or starch as a substrate, spray the above water-extracted extract as a binder into the one-step granulator, open the air inlet and outlet, control the negative pressure of -0.05MPa to make the powder boil evenly in the granulator tank, and then Heat to control the temperature of the material at 50°C, and carry out one-step granulation, and the granulation time is 3 hours; carry out granulation on the granules made by one-step granulation, add appropriate amoun...

Embodiment 3

[0030] Boil 35g of Motherwort, 20g of Rhizoma Cyperi, 20g of Passepartout, 20g of Rhizoma Chuanxiong, 20g of Wangbuliuxing, and 20g of Miltonia Spatholobus with water, and extract twice. hour; the amount of water added for the second extraction is 10 times the amount of the drug, and the extraction time is 3 hours; add ethanol alcohol precipitation, adjust the alcohol degree to 30%, filter, and concentrate the alcohol precipitation solution to become a water extraction alcohol precipitation solution with a relative density of 1.05 Dilute extract; put dextrin or starch in the one-step granulator as a substrate, spray the above-mentioned water-extracted alcohol-sinking dilute extract as a binder into the one-step granulator, open the air inlet and outlet, and control it at -0.03MPa The negative pressure makes the powder boil evenly in the tank of the granulator, and then heats the material to control the temperature at 40°C for one-step granulation. The granulation time is 4 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com