Fabric printing and dyeing device with electron accelerator mechanism

A technology of electron accelerator and dyeing device, applied in printing device, local fabric treatment, printing, etc., can solve the problems of large fiber damage, large energy consumption, long dyeing time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

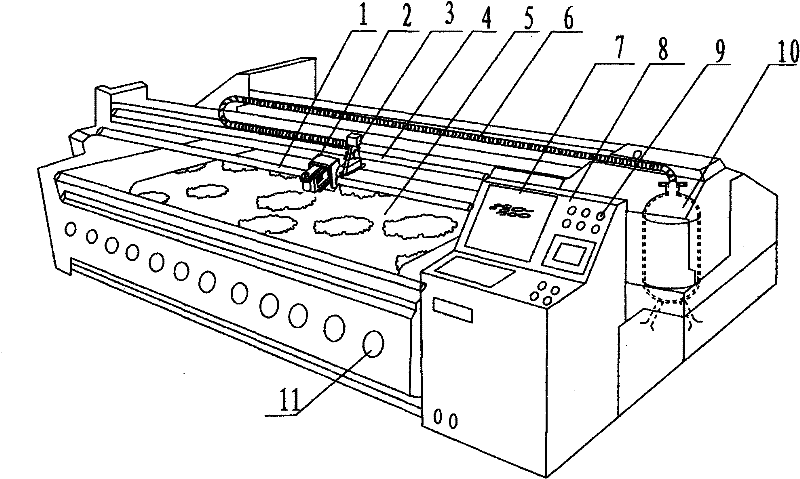

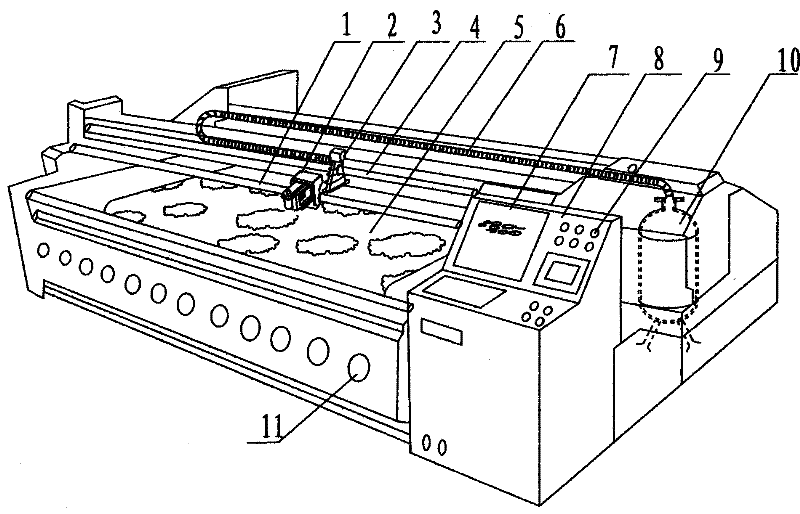

[0011] Such as figure 1 As shown, a fabric printing and dyeing device with an electron accelerator mechanism has an inkjet color print head 2 installed on the print head guide rail 1, and the inkjet color print head 2 is controlled by the control cabinet 8 to execute related dyeing procedures Can slide printing dyeing along print head guide rail 1 when. The printing head guide rail 1 is installed perpendicular to the forward direction of the fabric when it is printed and dyed, and the printing and dyeing device also includes an electron accelerator mechanism, so that the fabric is firstly modified by high-speed electron beam radiation, and then printed and dyed.

[0012] Described electron accelerator mechanism comprises electron accelerator launch gun 3, launch gun guide rail 4, ray delivery channel 6 and electron acceleration device 10, wherein, launch gun guide rail 4 is installed in parallel with printing head guide rail 1, and electron accelerator launch gun 3 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com