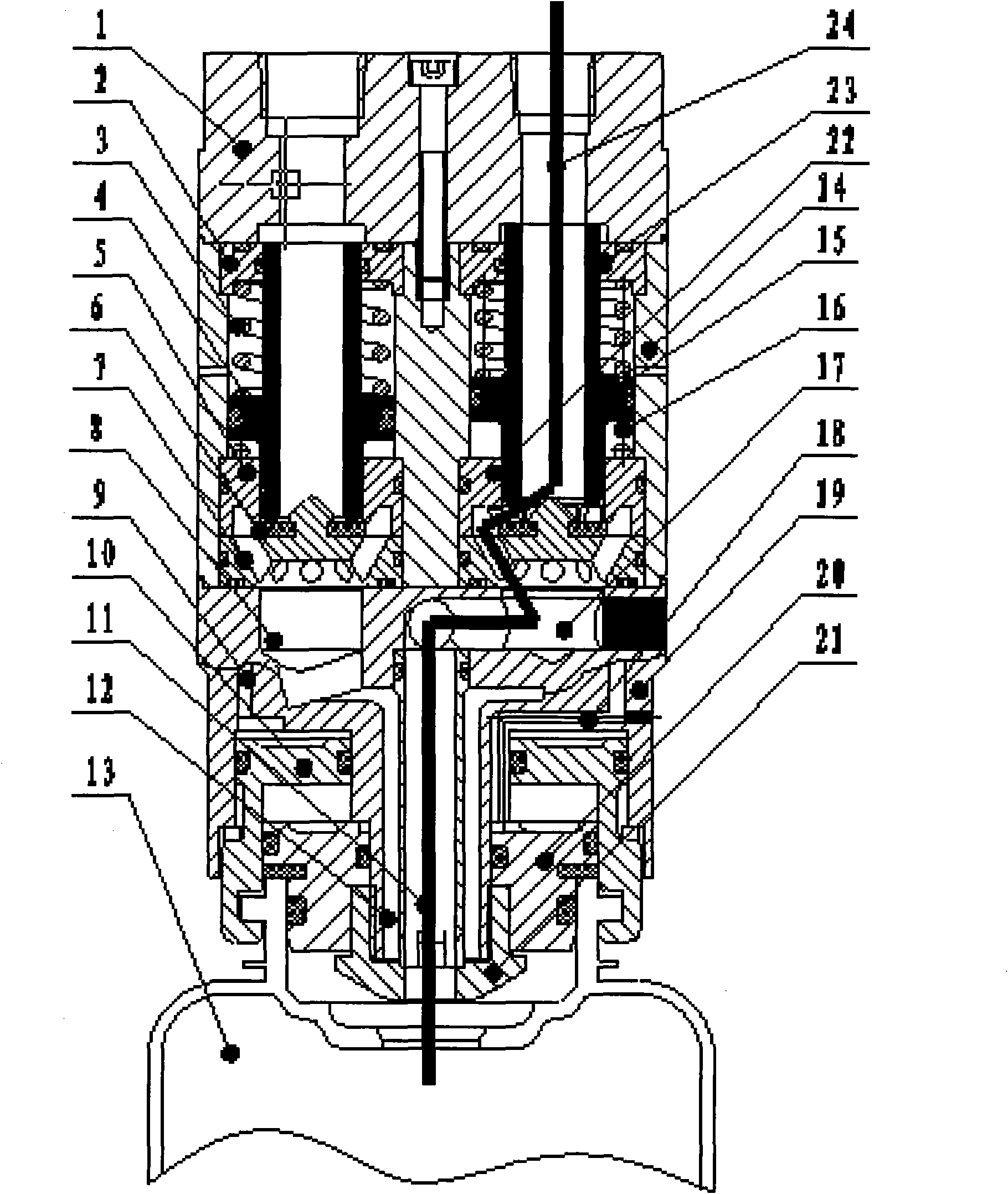

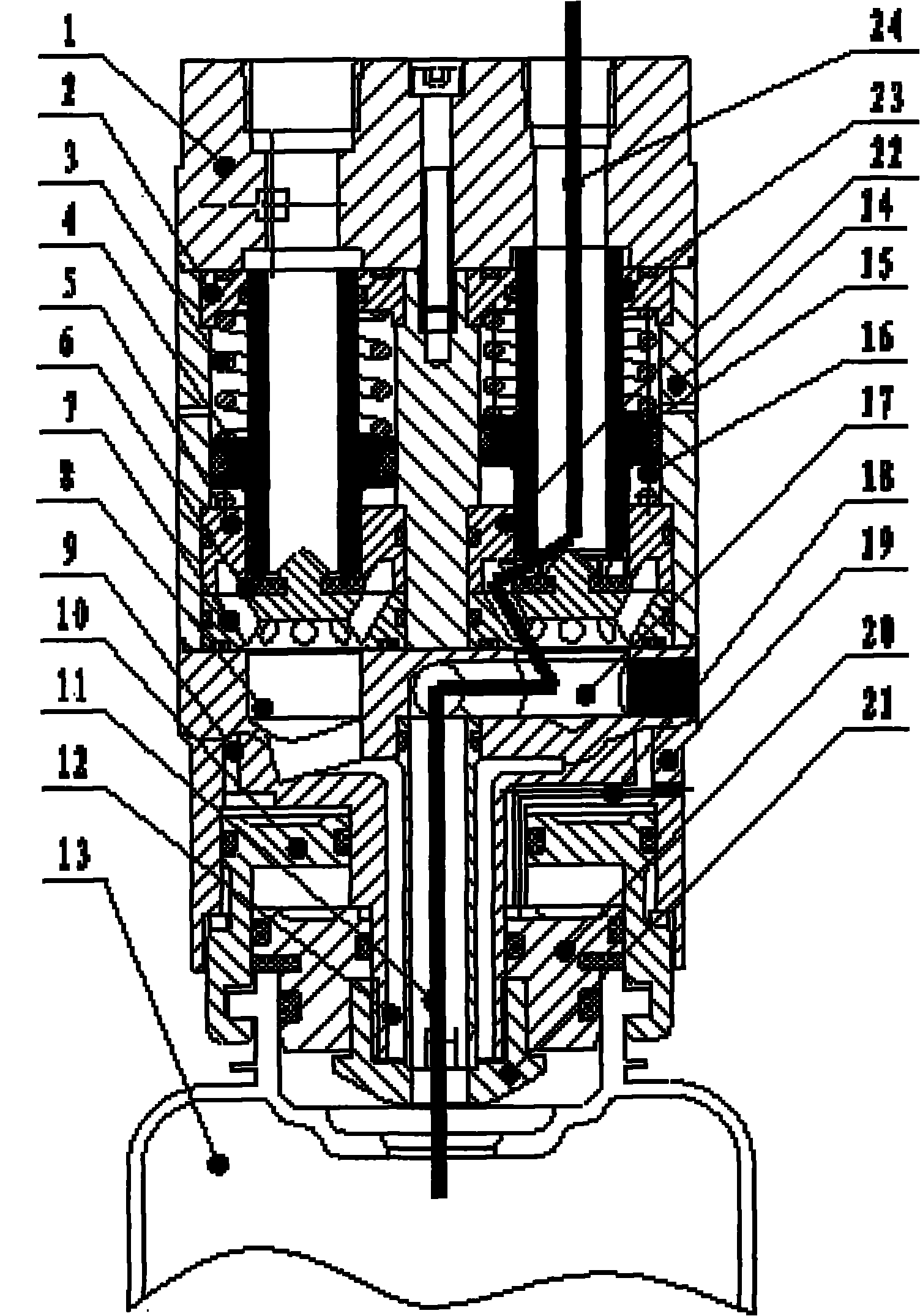

Filling gun with three in-built hollow valve rods

The technology of filling gun and valve stem is applied in the field of filling gun, which can solve the problems of heavy weight, large volume of filling gun, difficult operation, etc., and achieve the effect of good sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Such as figure 1 As shown, there are three passages of vacuum, filling and withdrawal in the filling gun, which are respectively connected with the pipeline of the equipment through the pipe thread on the three-hole valve cover (1). No matter the hollow valve stem (4) is in the closed position or the hollow valve stem (15) is in the open position, the hollow parts are respectively used as a part of the three passages of vacuum, filling and withdrawal. The lower end of the hollow valve stem (4) in the closed position is tightly pressed against the gasket (6) under the action of the spring (3) to act as a seal, so that the hollow part of the hollow valve stem (4) in the closed position and the filling , The withdrawal path (8) is completely separated. After the hollow valve stem opens the air intake hole (16) to pass in the compressed air, push the valve stem to the position of the hollow valve stem (15) in the open position. At this time, the lower end of the hollow val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com