CA (cement and asphalt) mortar for CRTS II slab ballastless tracks

A slab ballastless track and mortar technology, applied in the field of CA mortar, can solve the problems of short application time of CRTS Ⅱ slab ballastless track, insufficient research on formula and influencing factors, etc., to improve compressive strength and flexural strength, The effect of small loss of expansion and fluidity and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

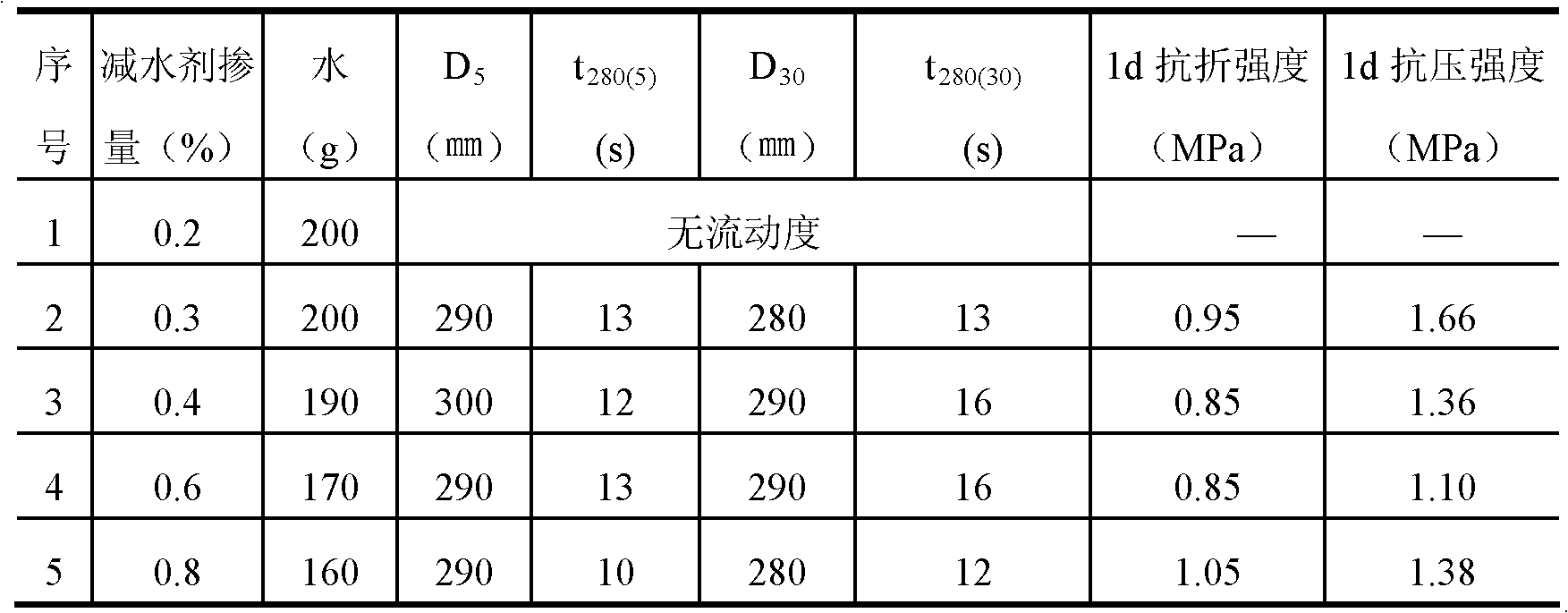

Embodiment 1

[0021] Preparation of emulsified asphalt: prepare materials by weight, add 1.8 parts of emulsifier, 0.3 part of suspending agent, 0.3 part of stabilizer, 0.6 part of polycarboxylate water reducer to 39 parts of water at 65 °C, and 58.0 parts of 70 parts heated to 125 °C No. base asphalt is added to the emulsifier together, and the emulsified asphalt is obtained through shear emulsification. The polycarboxylate superplasticizer in the emulsified asphalt has a reduced solid content of 0.29%. Its performance indicators are shown in Table 3:

[0022] Table 3 Performance indicators of emulsified asphalt

[0023]

[0024] Preparation of cement asphalt mortar: by weight, add 8.72 parts of water, 1.28 parts of P emulsion, 11.54 parts of emulsified asphalt, 0.77 parts of melamine water reducer, and 0.2 parts of defoamer into the mixer at a speed of 30 rpm Stir for 30 seconds, increase the speed to 120 rpm, then add 25.65 parts of cement, 51.33 parts of sand, 0.51 parts of expansio...

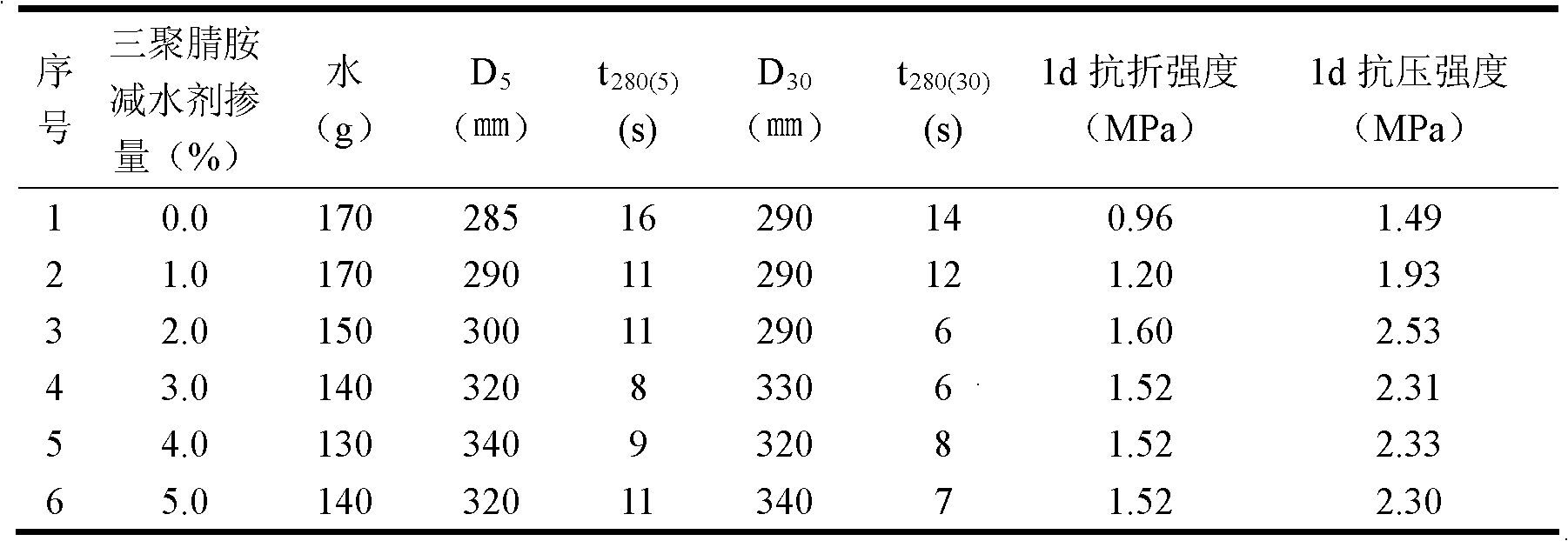

Embodiment 2

[0030] Preparation of emulsified asphalt: prepare materials by weight, add 1.8 parts of emulsifier, 0.3 part of suspending agent, 0.3 part of stabilizer and 0.8 part of polycarboxylate water reducer to 39 parts of water at 65 ° C, and 57.8 parts of 70 parts heated to 125 ° C No. base asphalt is added to the emulsifier together, and the emulsified asphalt is obtained through shear emulsification. The polycarboxylate superplasticizer in the emulsified asphalt has a solid content of 0.38%, and its performance indicators are shown in Table 5:

[0031] Table 5 Performance indicators of emulsified asphalt

[0032]

[0033]

[0034] Preparation of cement asphalt mortar: by weight, add 7.78 parts of water, 1.30 parts of P emulsion, 11.66 parts of emulsified asphalt, 0.78 parts of melamine water reducer, and 0.21 parts of defoamer into the mixer at a speed of 30 rpm Stir for 30 seconds, increase the speed to 120 rpm, then add 25.92 parts of cement, 51.83 parts of sand, 0.52 part...

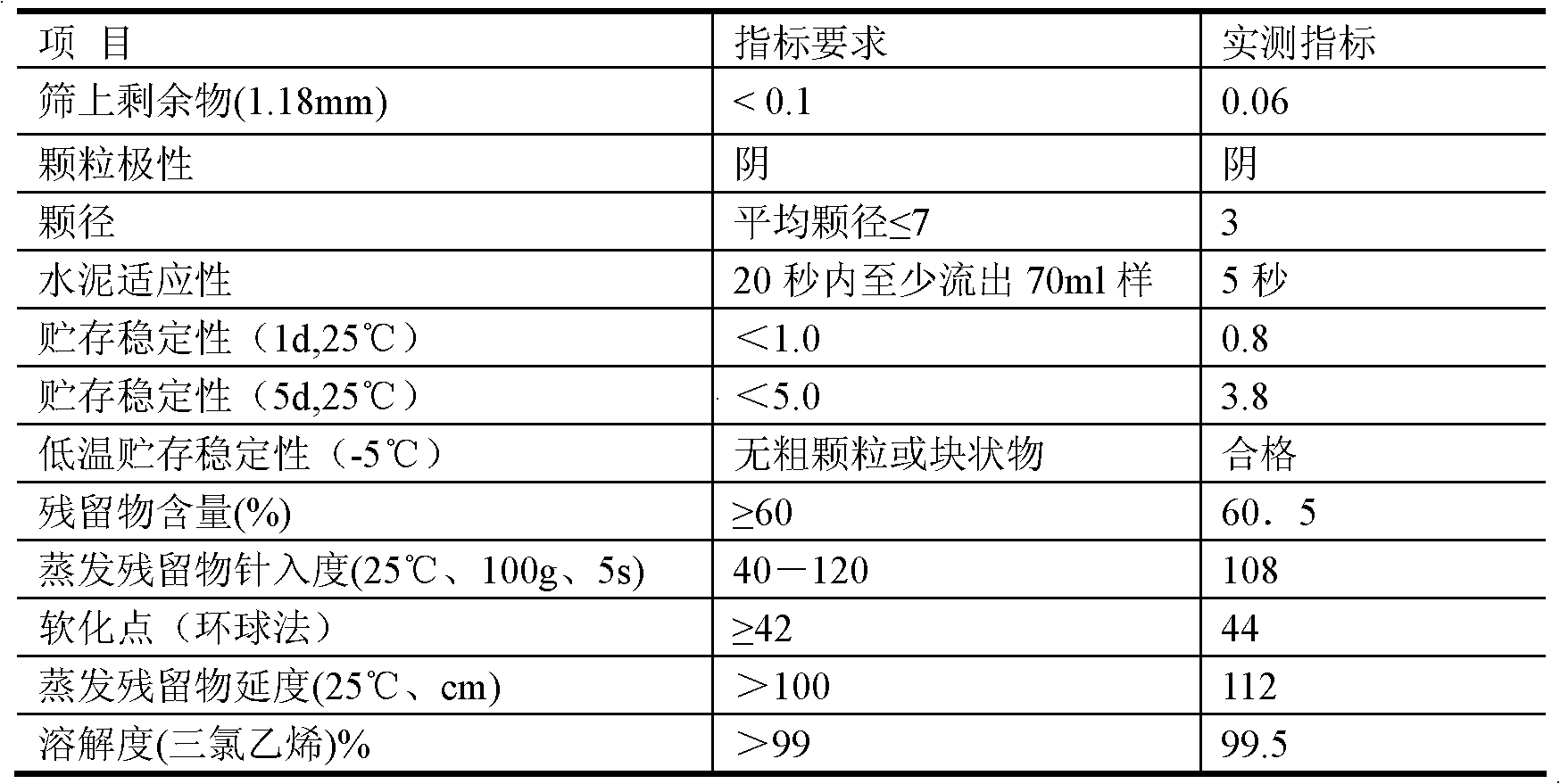

Embodiment 3

[0039] Preparation of emulsified asphalt: prepare materials by weight, add 1.8 parts of emulsifier, 0.3 part of suspending agent, 0.3 part of stabilizer, and 1.0 part of polycarboxylate water reducer to 39 parts of water at 65 ° C, and 57.6 parts of 70 parts heated to 125 ° C No. base asphalt is added to the emulsifier together, and the emulsified asphalt is obtained through shear emulsification. The polycarboxylate superplasticizer in the emulsified asphalt has a reduced solid content of 0.48%. Its performance indicators are shown in Table 7:

[0040] Table 7 Performance indicators of emulsified asphalt

[0041]

[0042]Preparation of cement asphalt mortar: by weight, add 7.54 parts of water, 1.30 parts of P emulsion, 11.69 parts of emulsified asphalt, 0.78 parts of melamine water reducer, and 0.21 parts of defoamer into the mixer at a speed of 30 rpm Stir for 30 seconds, increase the speed to 120 rpm, then add 25.99 parts of cement, 51.97 parts of sand, 0.52 parts of ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com