Method for preparing high-concentration nano aluminum hydroxide aqueous dispersion and prepared product

A nano-aluminum hydroxide and water-based dispersion technology, applied in chemical instruments and methods, dyed organic silicon compound treatment, dyed low-molecular organic compound treatment, etc., can solve the problems of low efficiency and limit the application of nano-aluminum hydroxide, Achieve the effects of fast ink absorption, bright colors and guaranteed dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A beaker (500 mL) containing 200 g of deionized water was placed under a toothed stirring paddle with a diameter of 5 cm, and the speed of the stirrer was 200 rpm. During stirring, 3.3 g of nitric acid (30 wt.%) was added and dispersed for 5 min.

[0055] The stirring speed was raised to 1000 rpm, and 111 g of nanometer aluminum hydroxide was gradually added into the acid-containing water with a spoon. After dispersing at a speed of 1000rpm for 20min, then gradually increase the speed to 2000rpm, and disperse at this speed for 30min.

[0056] Add 2.2g of glycidoxypropyltrimethoxysilane, adjust the speed to 3000rpm, and disperse for another 120min.

[0057] The concentration of the nano aluminum hydroxide aqueous dispersion is 35wt.%.

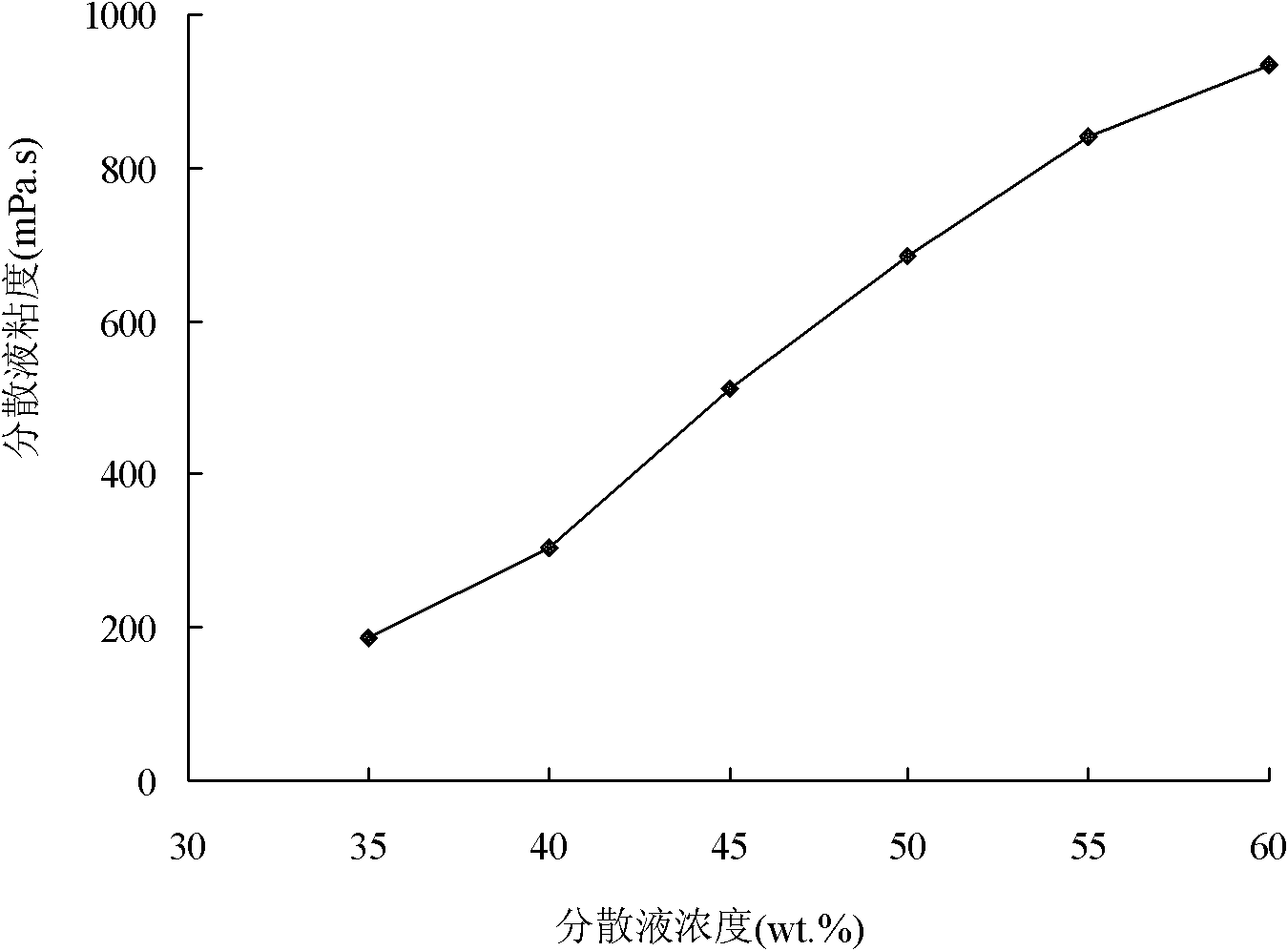

[0058] Test the viscosity of this concentration nano-aluminum hydroxide aqueous dispersion liquid, obtain the relationship figure of dispersion liquid concentration and viscosity together with the viscosity of other concentration disper...

Embodiment 2

[0062] Substantially prepare nano-aluminum hydroxide aqueous dispersion liquid by the same method described in embodiment 1, but be different from embodiment 1: the amount of adding nitric acid (30wt.%) is 4.1g, and the amount of nano-aluminum hydroxide is 138g, The amount of glycidoxypropyltrimethoxysilane was 2.8 g.

[0063] The concentration of the nano aluminum hydroxide aqueous dispersion is 40wt.%.

[0064] Also test the viscosity of the nano-aluminum hydroxide aqueous dispersion, and investigate the application effect.

Embodiment 3

[0066] Substantially prepare nano-aluminum hydroxide aqueous dispersion liquid by the same method described in embodiment 1, but be different from embodiment 1: the amount of adding nitric acid (30wt.%) is 5.1g, and the amount of nano-aluminum hydroxide is 171g, The amount of glycidoxypropyltrimethoxysilane was 3.4 g.

[0067] The concentration of the nano aluminum hydroxide aqueous dispersion is 45wt.%.

[0068] Also test the viscosity of the nano-aluminum hydroxide aqueous dispersion, and investigate the application effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com