High-capacity deceleration clutch for full-automatic agitator washing machine

A deceleration clutch and stirring technology, which is applied to other washing machines, the combination and application of couplings and brakes, etc., can solve the problems that the clutch is not suitable for large-capacity stirring washing machines, the clutch is noisy, and the washing capacity is large. The effect of service life and working reliability, reducing impact, improving strength and bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific drawings and embodiments.

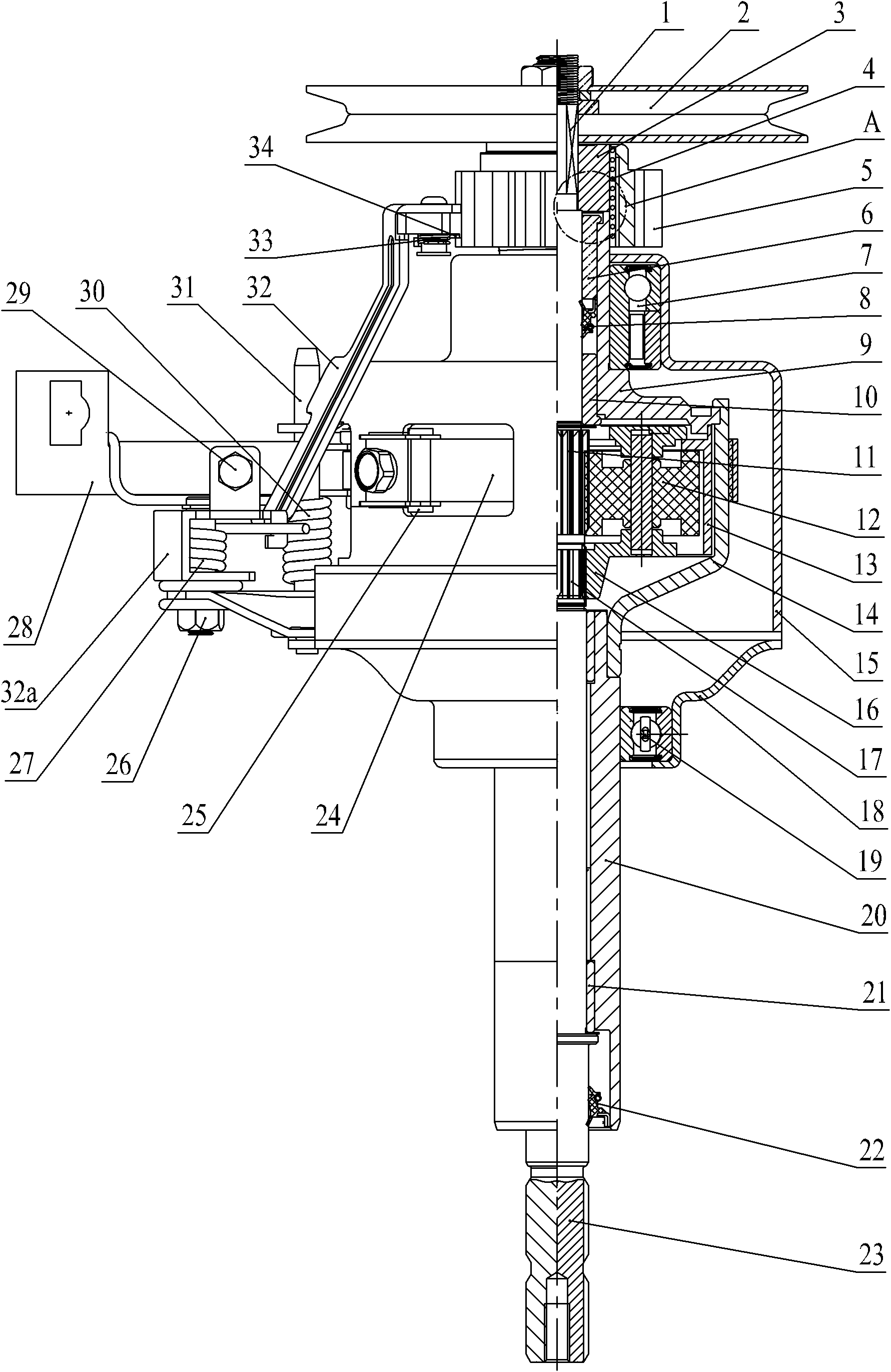

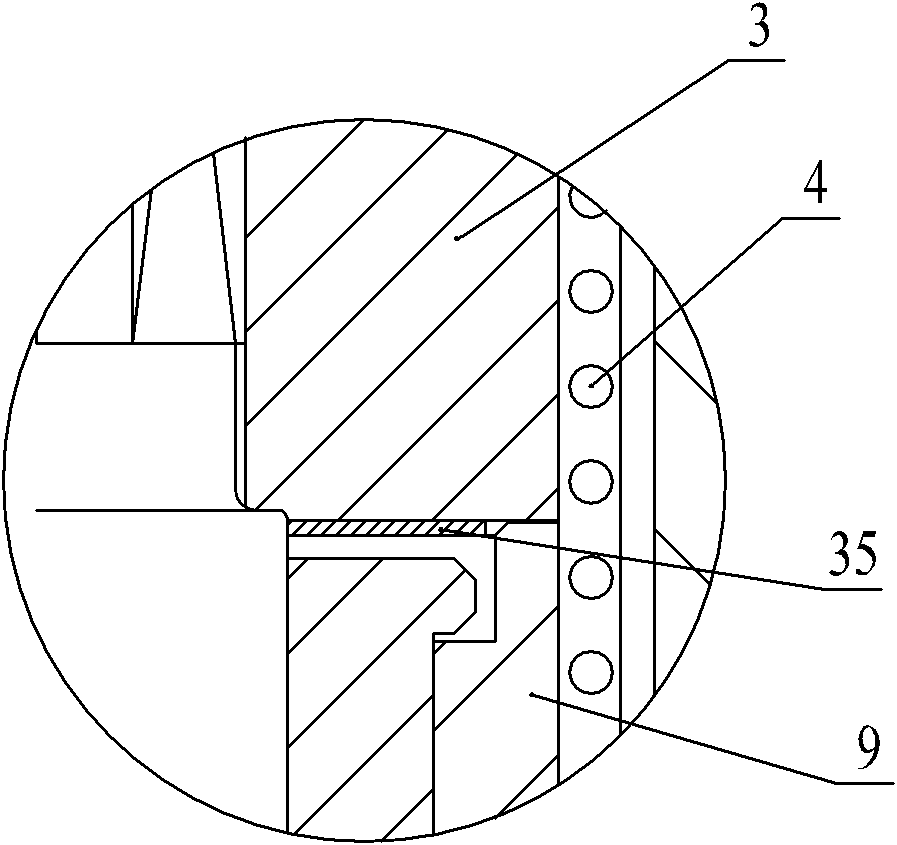

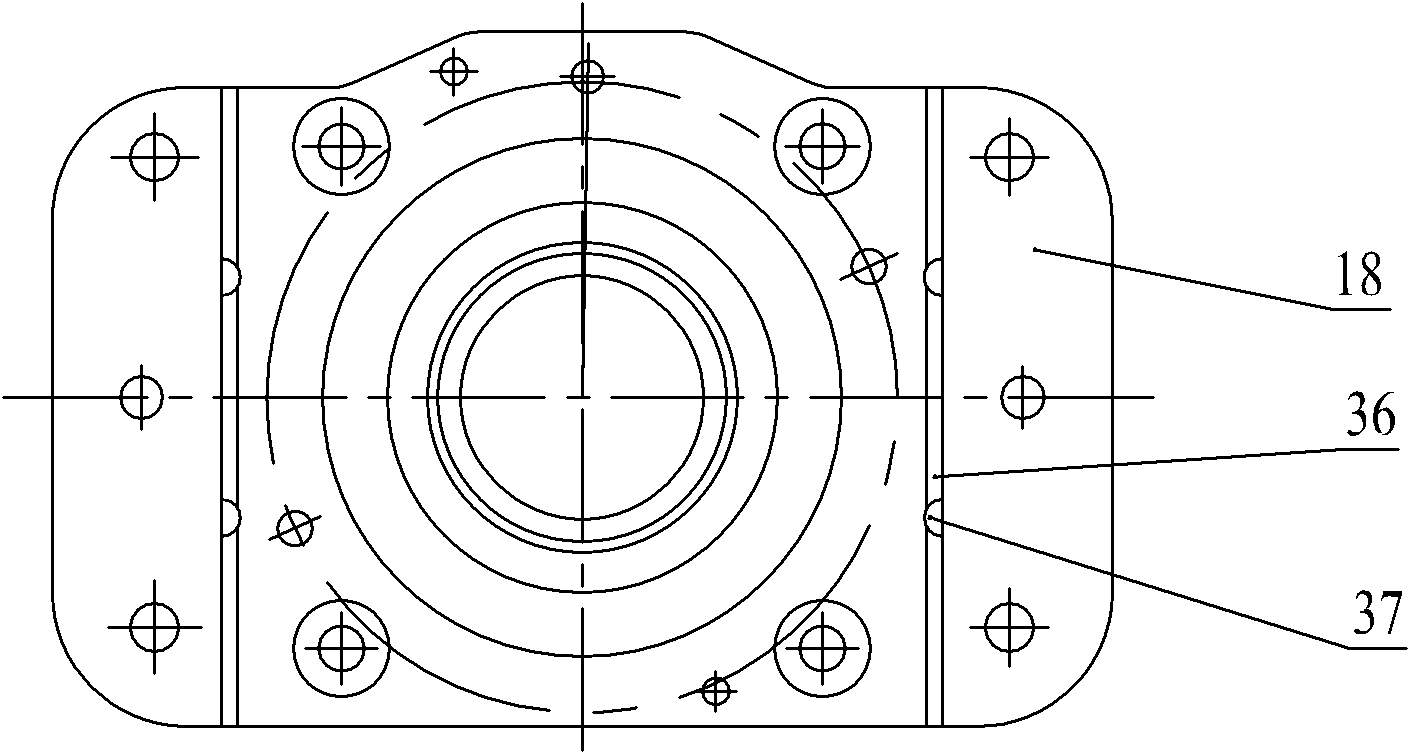

[0024] As shown in the figure: the large-capacity deceleration clutch in the embodiment is mainly composed of a transmission shaft 1, a pulley 2, a clutch sleeve 3, a torsion spring clutch spring 4, a ratchet wheel 5, an upper shaft sleeve 6, an upper bearing 7, an oil seal 8, and a clutch shaft 9. Lower shaft sleeve 10, planetary gear 12, ring gear 13, brake wheel 14, housing 15, cover plate 18, lower bearing 19, dehydration shaft 20, shaft sleeve 21, lower oil seal 22, washing shaft 23, brake steel Belt 24, short pin 25, bolt 26, fork torsion spring 27, lever 28, adjustment screw 29, lever torsion spring 30, long pin 31, shift fork 32, pawl torsion spring 33, pawl 34 and plastic pad Parts such as sheet 35 are formed.

[0025] Such as figure 1 As shown, the transmission shaft 1 is used to receive the rotational power of the washing machine motor. The transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com