Construction process of concrete form water-stopping occlusion pile

A technology of concrete formwork and construction technology, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of difficult to guarantee the construction quality of rotary jet pile, complicated construction process and high construction cost, and achieve easy control of construction quality and application The effect of wide coverage and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

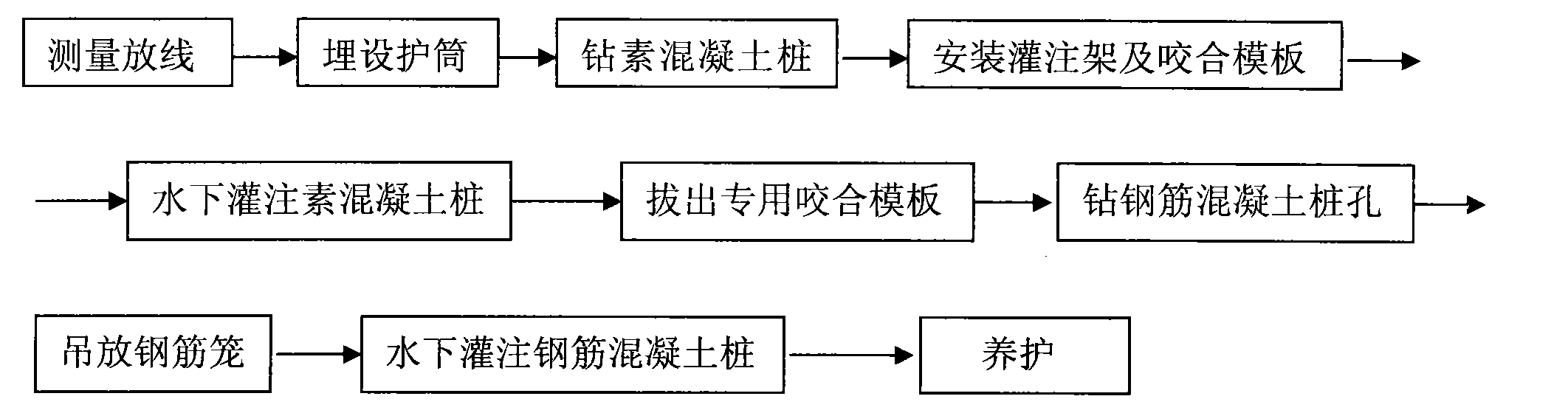

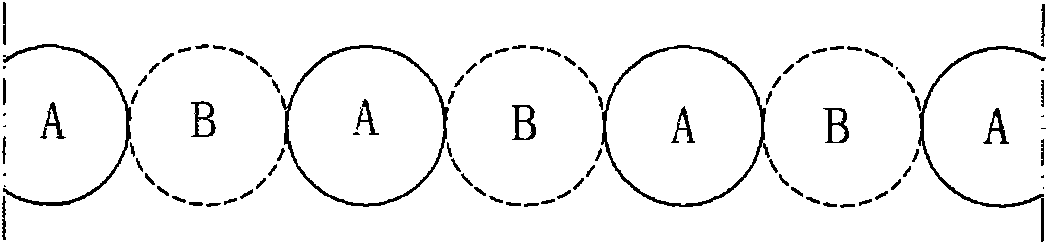

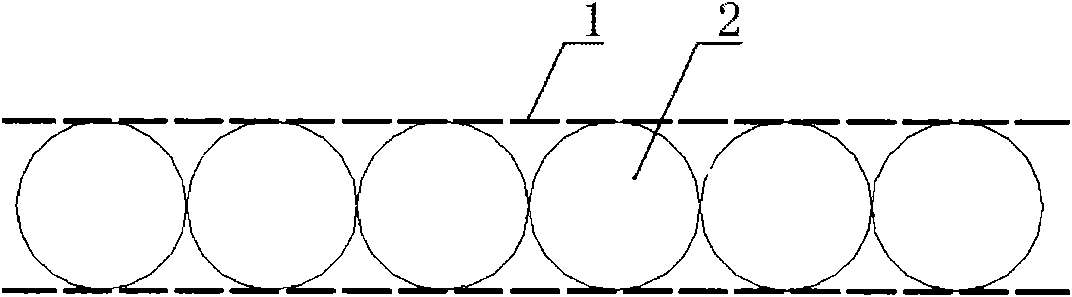

[0057] see Figure 1 to Figure 11 , the overall construction process of the occlusal pile of the present invention is: firstly carry out the construction of the plain concrete pile A, and form an arc-shaped groove A1 through a special occlusal template; In the shaped groove A1, the plain concrete pile A and the reinforced concrete pile B are occluded to form a curtain to achieve the purpose of water stop and water retention.

[0058] The specific construction process is: measuring and setting out → laying casing → drilling plain concrete pile holes → installing pouring frame and occlusal formwork → pouring plain concrete piles underwater → pulling out special occlusal formwork → drilling reinforced concrete pile holes → hoisting steel bars Cage → underwater pouring of reinforced concrete piles → maintenance.

[0059] The construction process is described in detail below:

[0060] 1. Measurement and setting out:

[0061] a. Plane control: measure and release the plane positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com