Vertical piano pre-positioned sound board

An upright piano and soundboard technology, applied in the field of musical instruments, can solve the problem that the sound source of an upright piano cannot be directly received by the player, and achieve the effects of easy molding, improved timbre, and improved structure and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 An upright piano front soundboard, which includes a soundboard frame, the soundboard frame has a soundboard frame hole, and a resonance soundboard is embedded in the soundboard frame hole, and the resonance soundboard is carbon fiber Board or carbon fiber and glass fiber composite board; the thickness of the resonance sound board is 1-2mm.

[0023] The invention provides a method for manufacturing the front soundboard of an upright piano: (1) Carbon fiber or glass fiber is impregnated with epoxy resin to make carbon fiber prepreg or glass fiber prepreg; (2) Carbon fiber is prepreg The cloth is superimposed layer by layer to form a multilayer cloth, or carbon fiber prepreg cloth and glass fiber prepreg cloth are staggered layer by layer to form a multilayer cloth; (3) At a temperature of 130°C, it is cured by a 500-ton press Hot press molding to obtain a carbon fiber board or a carbon fiber and glass fiber composite board, which is used as the front sound board...

Embodiment 2

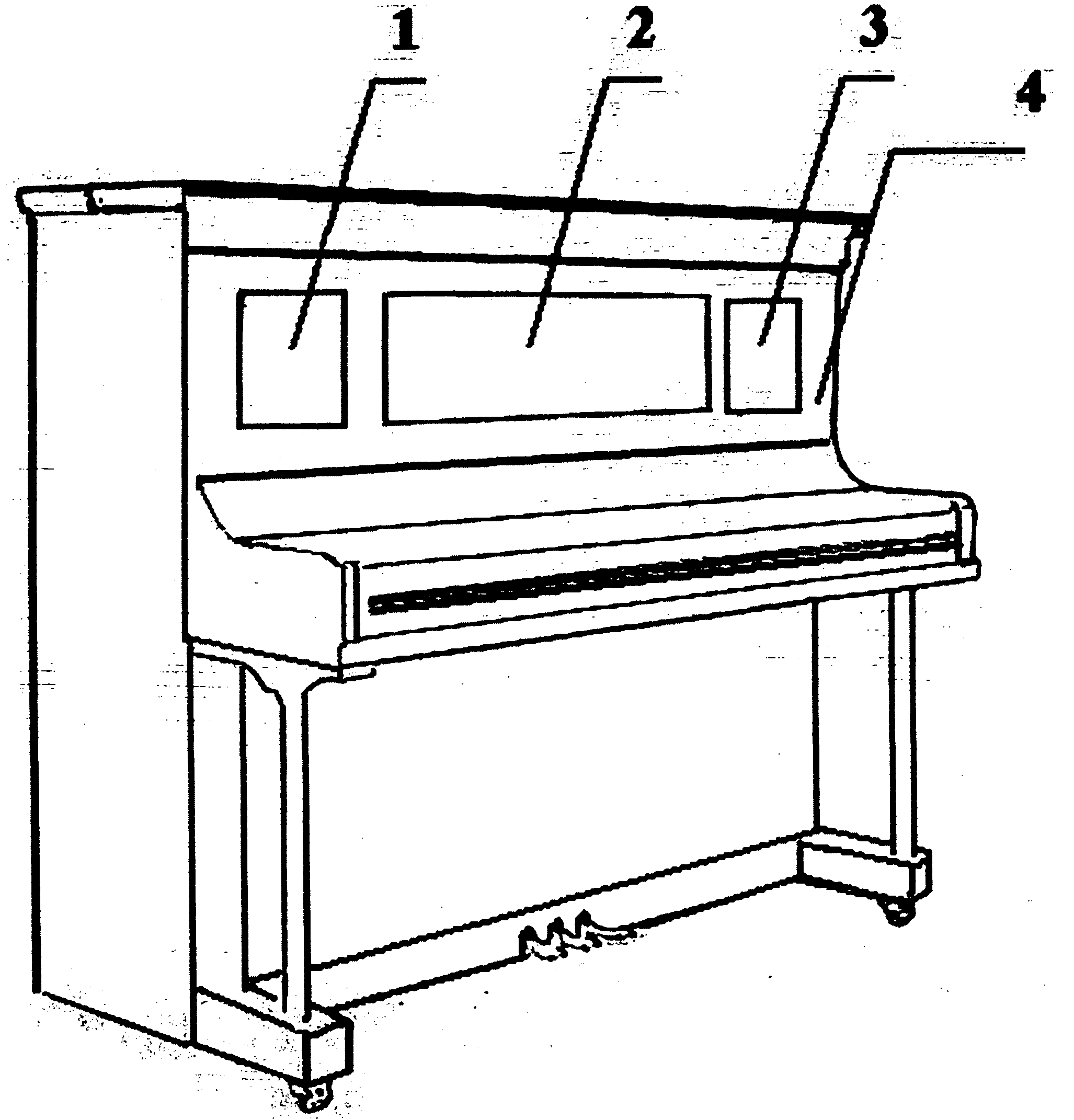

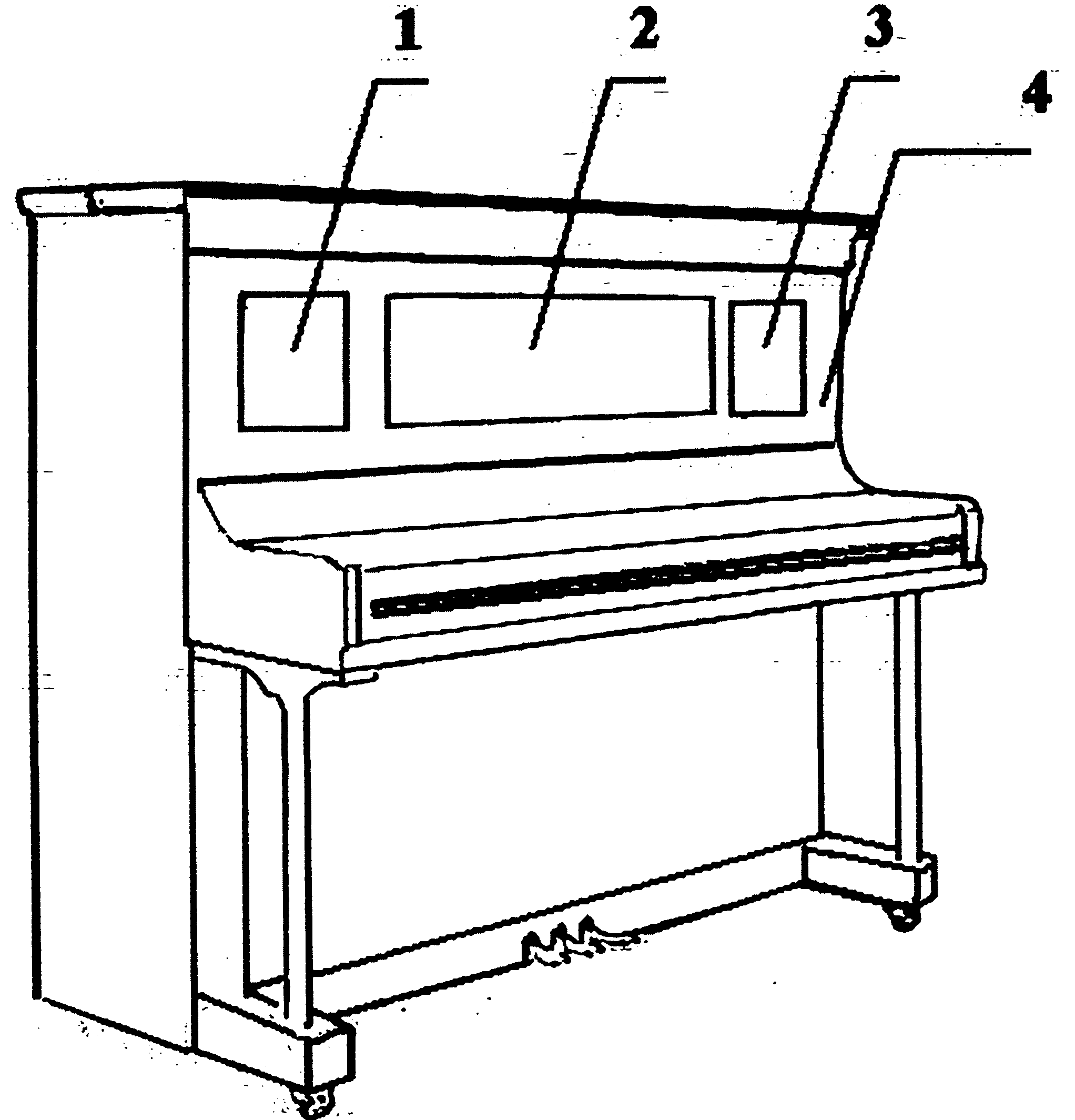

[0028] Example 2 such as figure 1 As shown, a front soundboard of an upright piano, the soundboard frame 4 has 3 soundboard frame holes arranged in sequence, and the treble resonance soundboard 1, the midrange resonance soundboard 2 and the bass resonance sound are embedded in sequence Board 3; The tweeter resonance sound board 1 is a carbon fiber and glass fiber composite board, the thickness of the composite board is 1.5mm, and the area is 290mm X 270mm; the midrange resonance sound board 2 is a carbon fiber board with an area of 690mm X 270mm; The bass sound board 3 is a carbon fiber board, the thickness of the carbon fiber board is 1.1mm, and the area is 290mm X 270mm.

[0029] The manufacturing method of the upright piano front soundboard is the same as in Example 1.

[0030] 1) Technical data of treble sounding board:

[0031] a. Material: 100% carbon fiber, 100% glass fiber composite;

[0032] b. Weaving: warp and weft crossed plain weaving. Carbon fiber cloth and glass fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com