Compositions comprising galactomannan and a process thereof

A composition and compound technology, applied in the field of new plant-derived compounds, can solve the problem of no data on the curative effect of galactomannan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

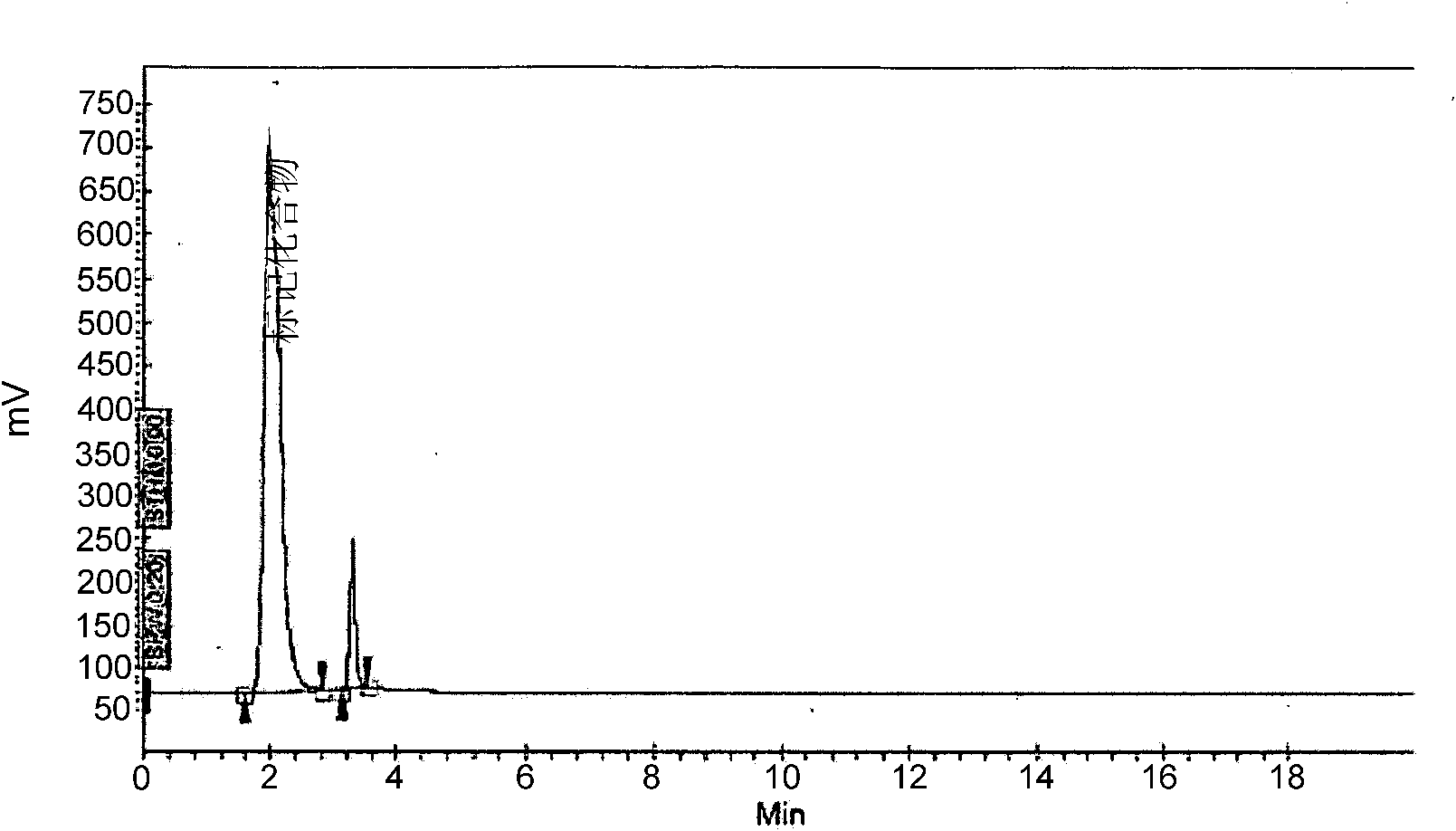

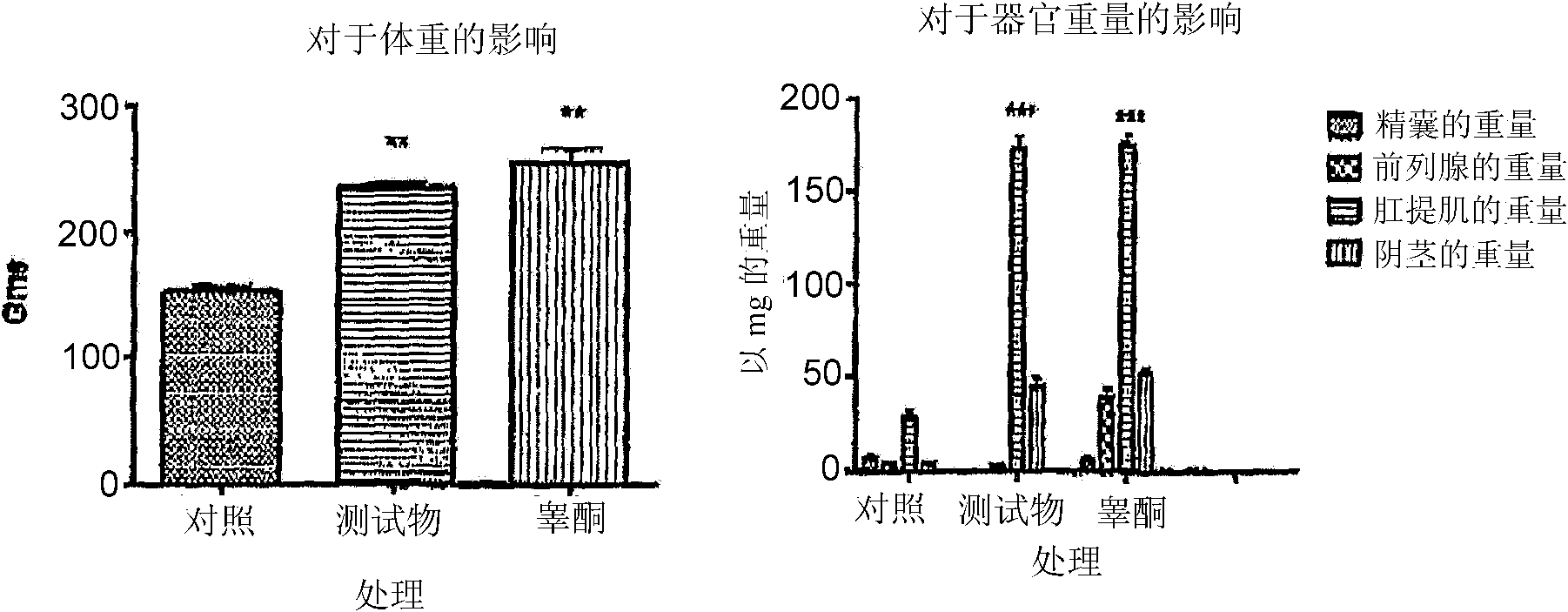

[0145] 1000 g of fenugreek seeds with a moisture content below 7% were crushed in a roller flaker to a thickness of 5 mm. The crushed material was packed in a column with a bed height of 300mm. 5 L of hexane was passed through the fenugreek layer and the eluate (or effluent) collected from the bottom was recirculated through the fenugreek layer at 35 °C for a period of 10 h. After 10 h, the fenugreek layer was drained free of hexane. A solvent mixture (8 L) comprising isopropanol and water in a 4:1 ratio was passed through the layer by recirculating the eluent over a period of 8 h at 35 °C. After 8 h, the fenugreek bed was drained free of extract and all extract was collected. The collected extracts were concentrated in vacuo at 50 °C to a semi-solid mass. The concentrated pellet was redissolved in 5 L of deionized water to obtain a clear solution. The clear aqueous solution was slowly passed through a column containing 500 mL of strong acid cation exchange resin in macrop...

Embodiment 2

[0152] 1000 g of fenugreek seeds with a moisture content below 7% were crushed in a roller mill to a thickness of 5 mm. The crushed material was packed in a column with a bed height of 300 mm. 5 L of hexane was passed through the fenugreek layer and the eluate (or effluent) collected from the bottom was recirculated through the fenugreek layer at 35 °C for a period of 10 h. After 10 h, the fenugreek layer was drained free of hexane. A solvent mixture (8 L) comprising ethanol and water in a 4:1 ratio was passed through the layer by recirculating the eluent over a period of 8 h at 35 °C. After 8 h, the fenugreek bed was drained free of extract and all extract was collected. The collected extracts were concentrated in vacuo at 50°C to a semi-solid mass. The concentrated pellet was redissolved in 5 L of deionized water to obtain a clear solution. The clear aqueous solution was passed slowly over a period of 2 h through a column containing 500 mL of strong acid cation exchange ...

Embodiment 3

[0163] 1000 g of fenugreek seeds with a moisture content below 7% were crushed in a roller mill to a thickness of 6 mm. The crushed material was packed in a column with a bed height of 300mm. 5 L of hexane was passed through the fenugreek layer and the eluate (effluent) collected from the bottom was recirculated through the fenugreek layer at 35° C. for a period of 10 h. After 10 h, the fenugreek layer was drained free of hexane. A solvent mixture (8 L) comprising methanol and water in a 4:1 ratio was passed through this layer by recirculating the eluent over a period of 8 h at 35 °C. After 8 h, the fenugreek bed was drained free of extract and all extract was collected. The collected extracts were concentrated in vacuo at 50°C to a semi-solid mass. The concentrated pellet was redissolved in 5 L of deionized water to obtain a clear solution. The clear aqueous solution was passed slowly over a period of 2 h through a column containing 500 mL of strong acid cation exchange r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com