Multilayer inductor and method for manufacturing the same

A technology of laminated inductors and manufacturing methods, applied in chemical instruments and methods, inductors, printed inductors, etc., can solve the problems of easy cracks, difficulty in simultaneous firing of internal conductors, deterioration of product temperature characteristics, etc. Less fluctuation, good DC overlap characteristics, stable production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0065] Hereinafter, the present invention will be described in further detail through implementation examples.

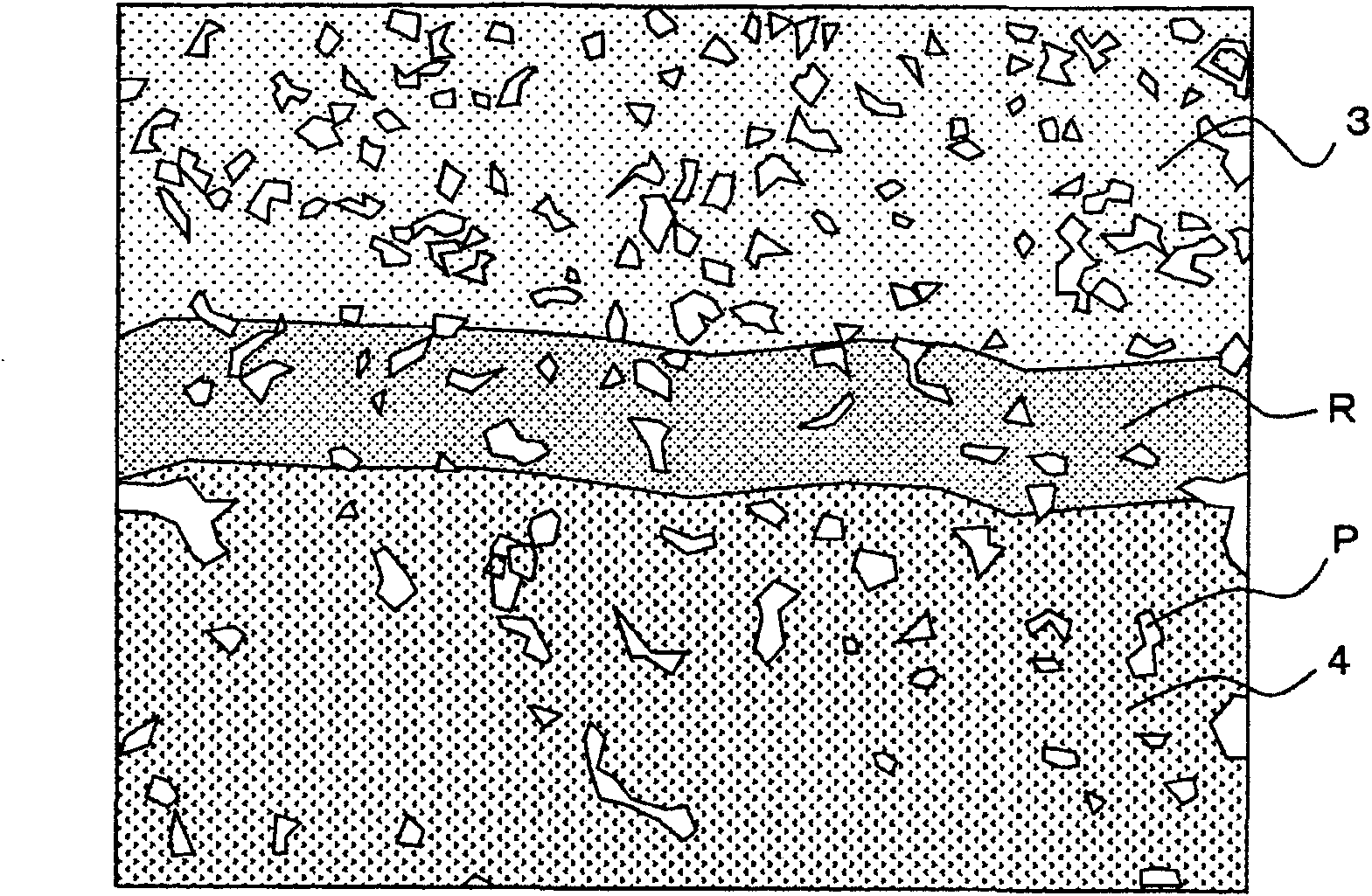

[0066] Add ethanol (solvent) and PVA-based binder to the Ni-Zn-Cu ferrite powder of the composition shown in Table 1, mix it, apply it on a PET film, and obtain a magnetic material sheet (magnetic material layer) . In addition, as shown in Table 1, in TiO 2 Main component and contains NiO, CuO, Mn 3 o 4 and ZrO 2 Dielectric powder (called "TiO 2Low-temperature firing material") powder was added and mixed with the same solvent and binder, and coated on a PET film to obtain a non-magnetic sheet (non-magnetic layer).

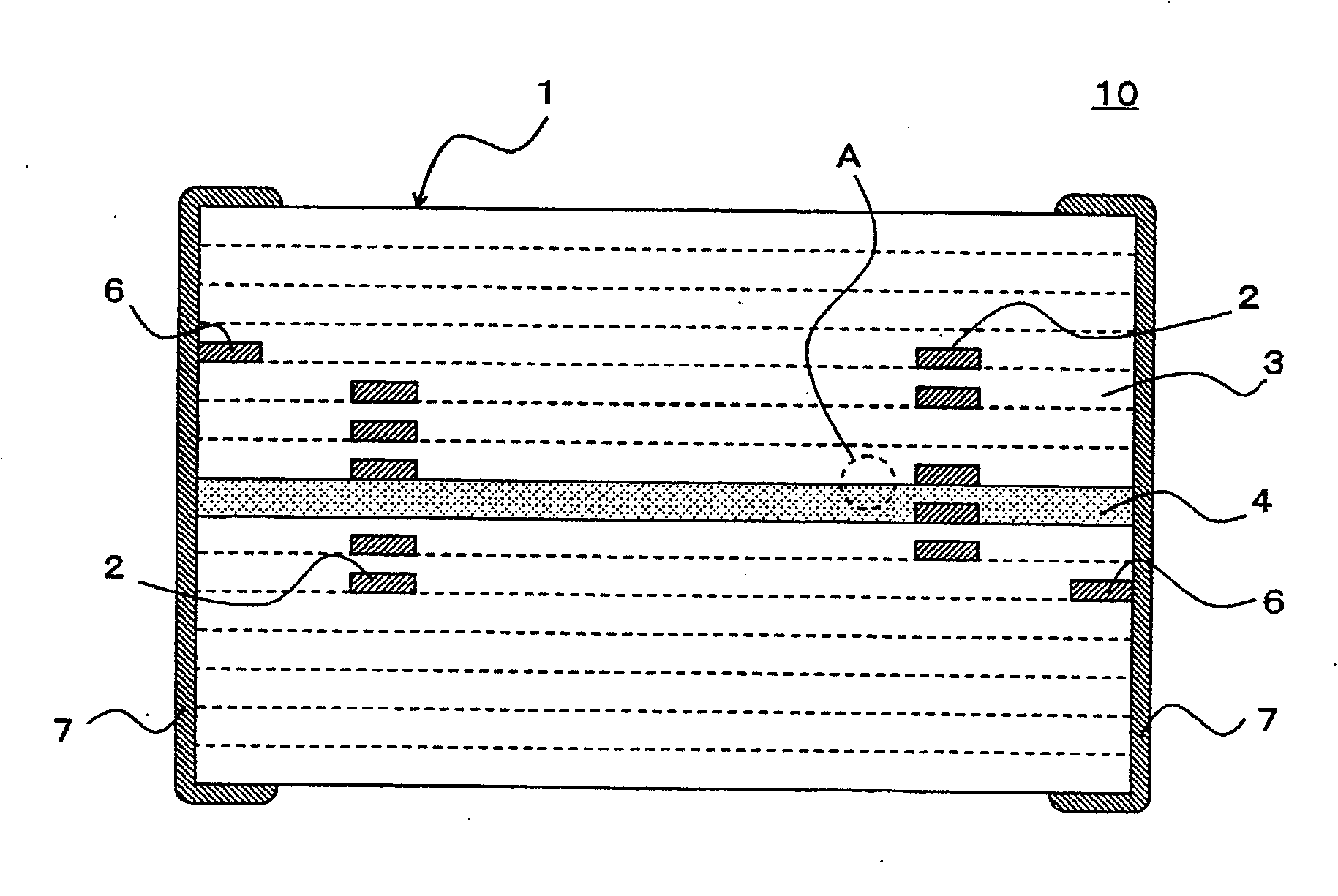

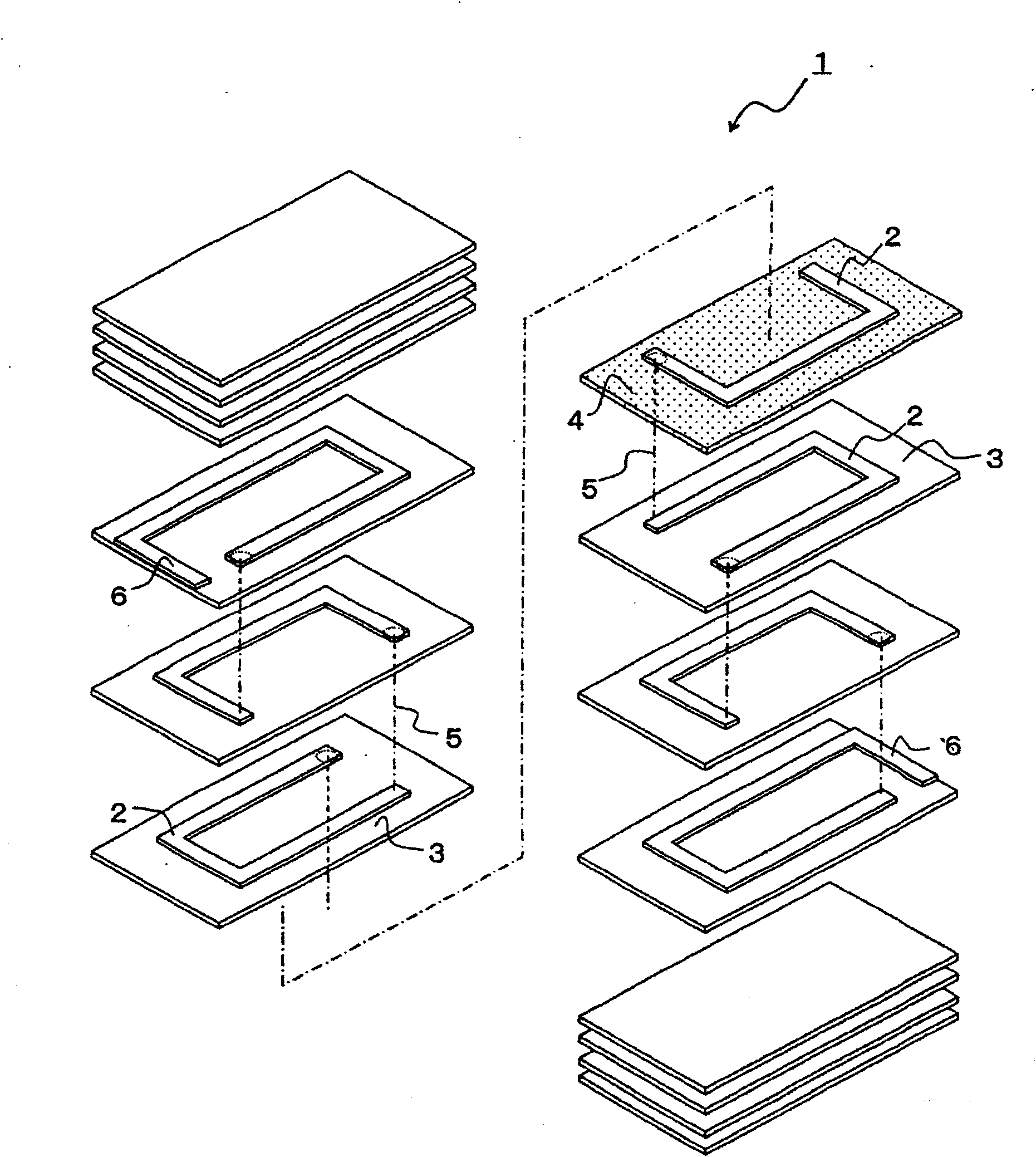

[0067] Electrodes (conductor layers for U-shaped coils) are printed on the obtained green sheet (Grinsite), and laminated to produce such as figure 2 Structured sheet laminates (TiO 2 The laminated body of the example of the low-temperature firing material), and the obtained sheet laminated body was cut into unit sizes to obtain a sheet-shaped un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com