Numerical control device of tank truck production line

A digital control, production line technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of tank leakage, complicated operation, lack of systematic control system for equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

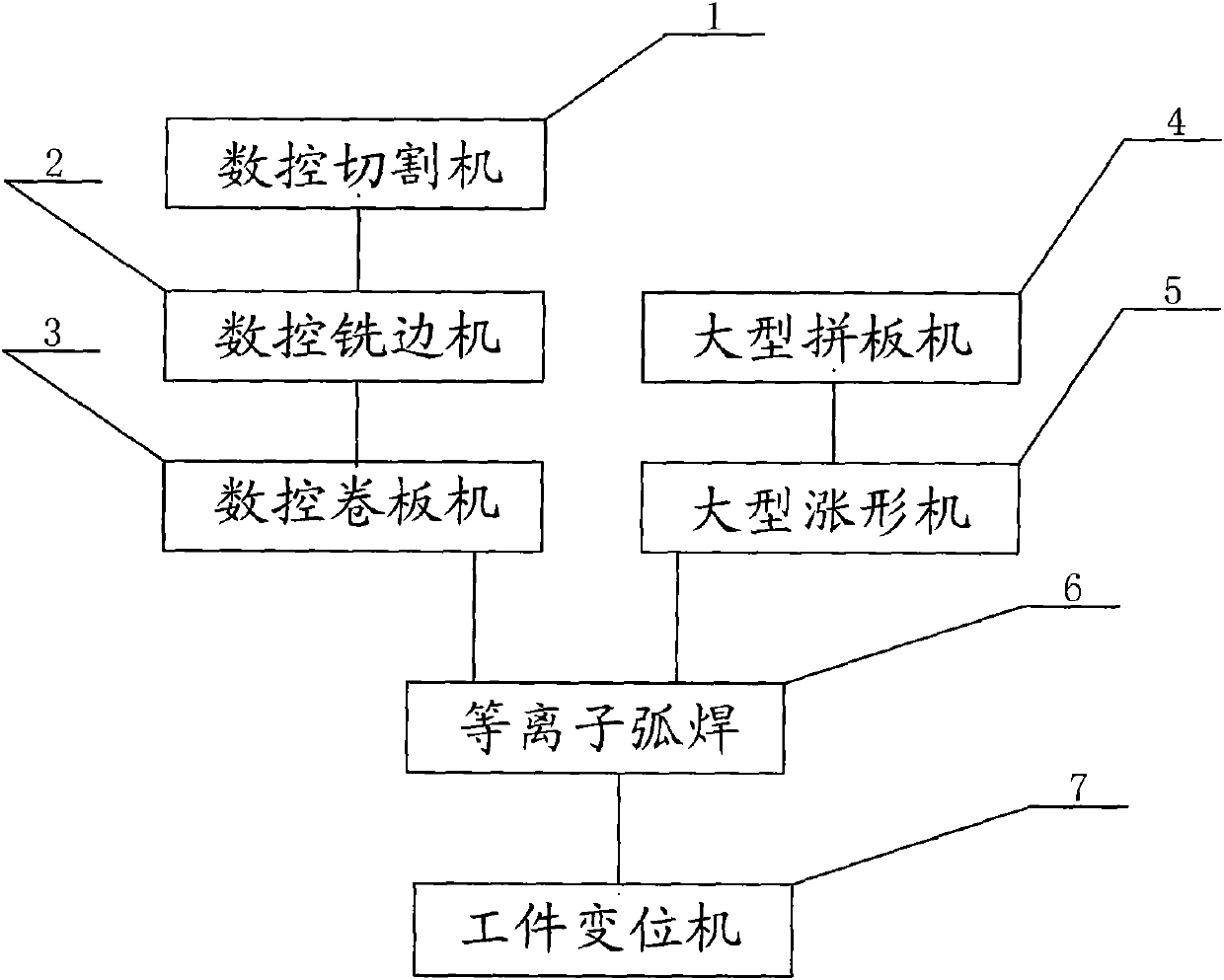

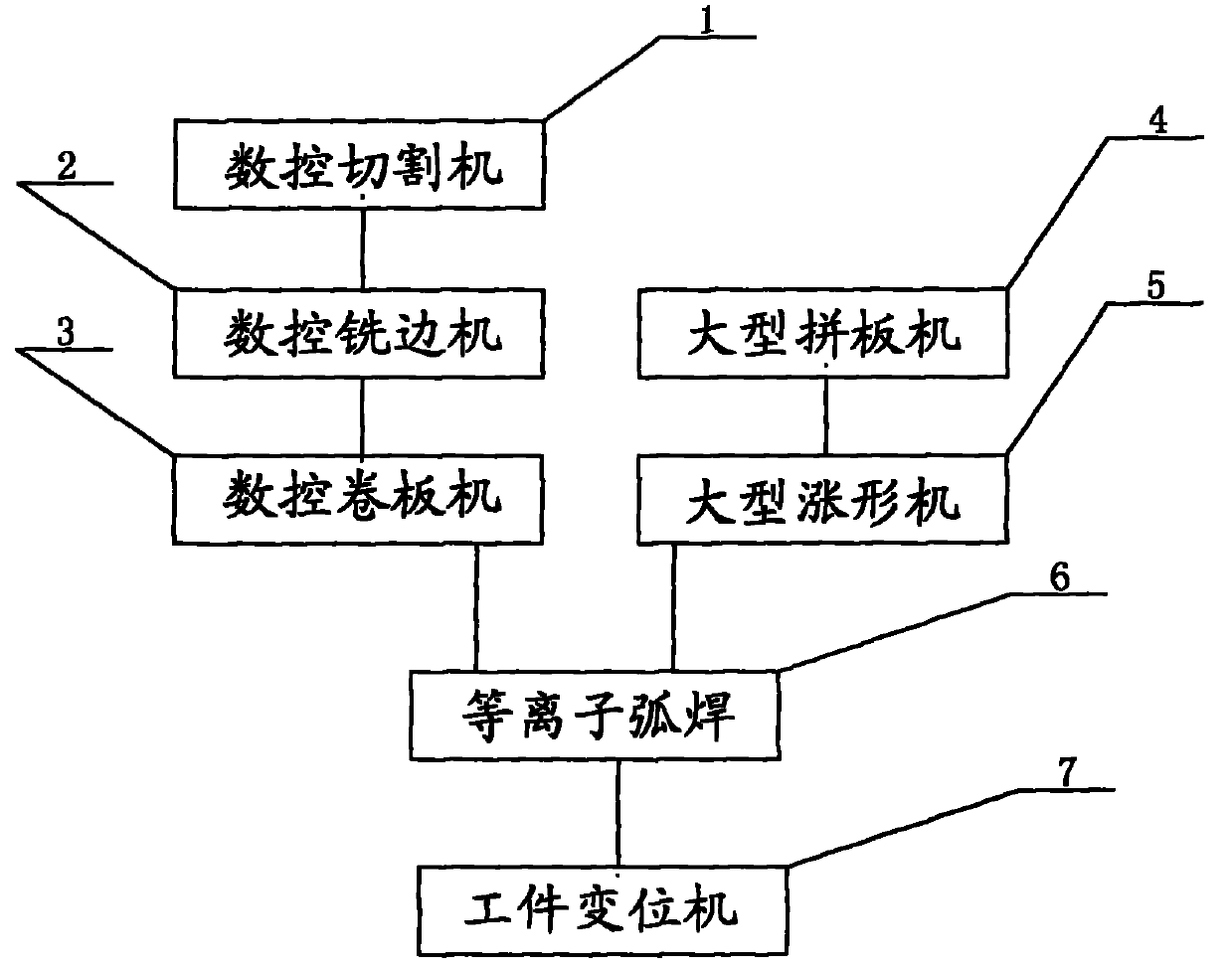

[0007] See figure 1 , This specific implementation adopts the following technical solutions: it includes CNC cutting machine 1, CNC milling machine 2, CNC bending machine 3, large-scale jointing machine 4, large-scale expansion machine 5, plasma arc welding 6 and workpiece displacement Machine 7; CNC cutting machine 1 is connected with CNC milling machine 2, CNC milling machine 2 is connected with CNC bending machine 3, large-scale jigsaw machine 4 is connected with large-scale expansion machine 5, CNC bending machine 3 and The large expansion machine 5 is connected to the plasma arc welding 6 at the same time, and the plasma arc welding 6 is connected to the workpiece positioner 7.

[0008] This specific implementation mode develops a set of remote centralized digital control system to realize integrated control of manufacturing process preparation, production planning arrangement, production process monitoring, production and material management.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com