Device and method for preparing gypsum by using semi-dry method to sinter flue gas desulfurization byproduct

A technology for desulfurization by-products and sintering flue gas, applied in separation methods, chemical instruments and methods, calcium/strontium/barium sulfate, etc., can solve the problems of no treatment plan, complex components and high content of sintering flue gas desulfurization by-products , to achieve the effect of reducing the processing cost and solving the problem of processing and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

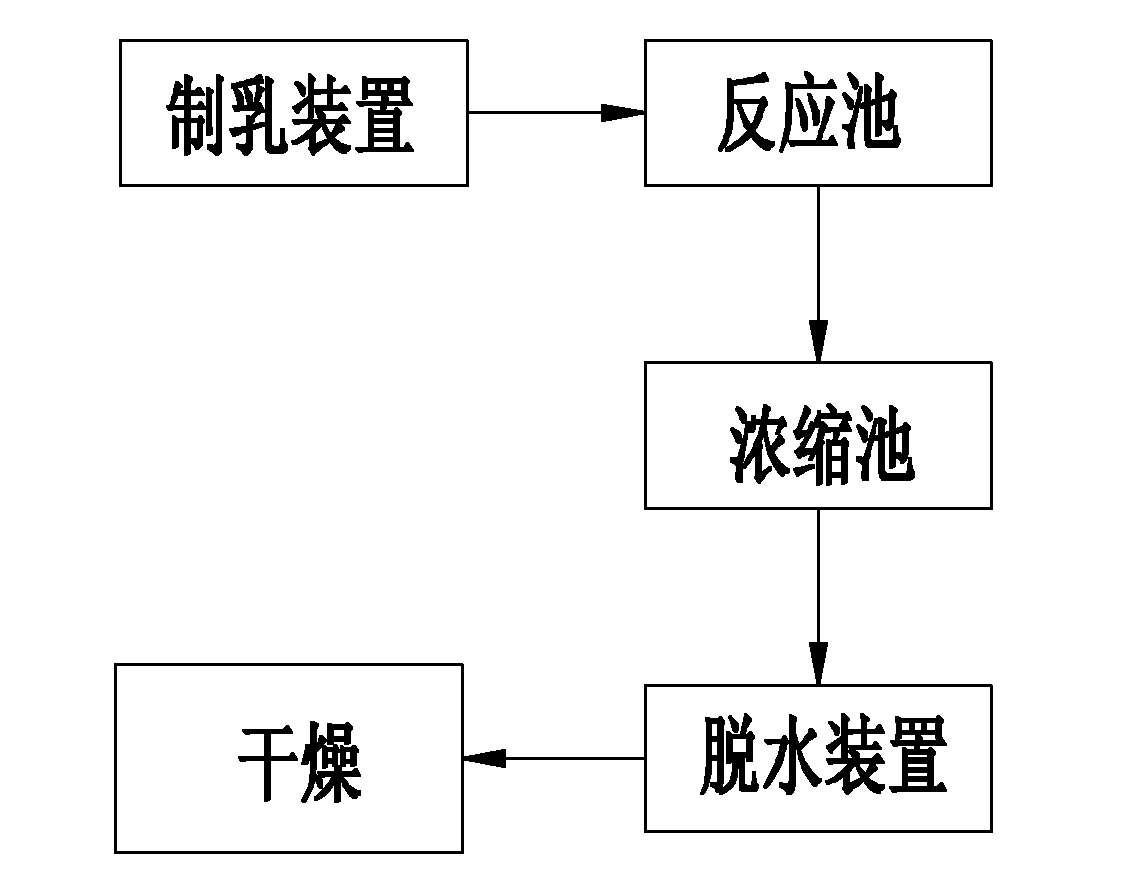

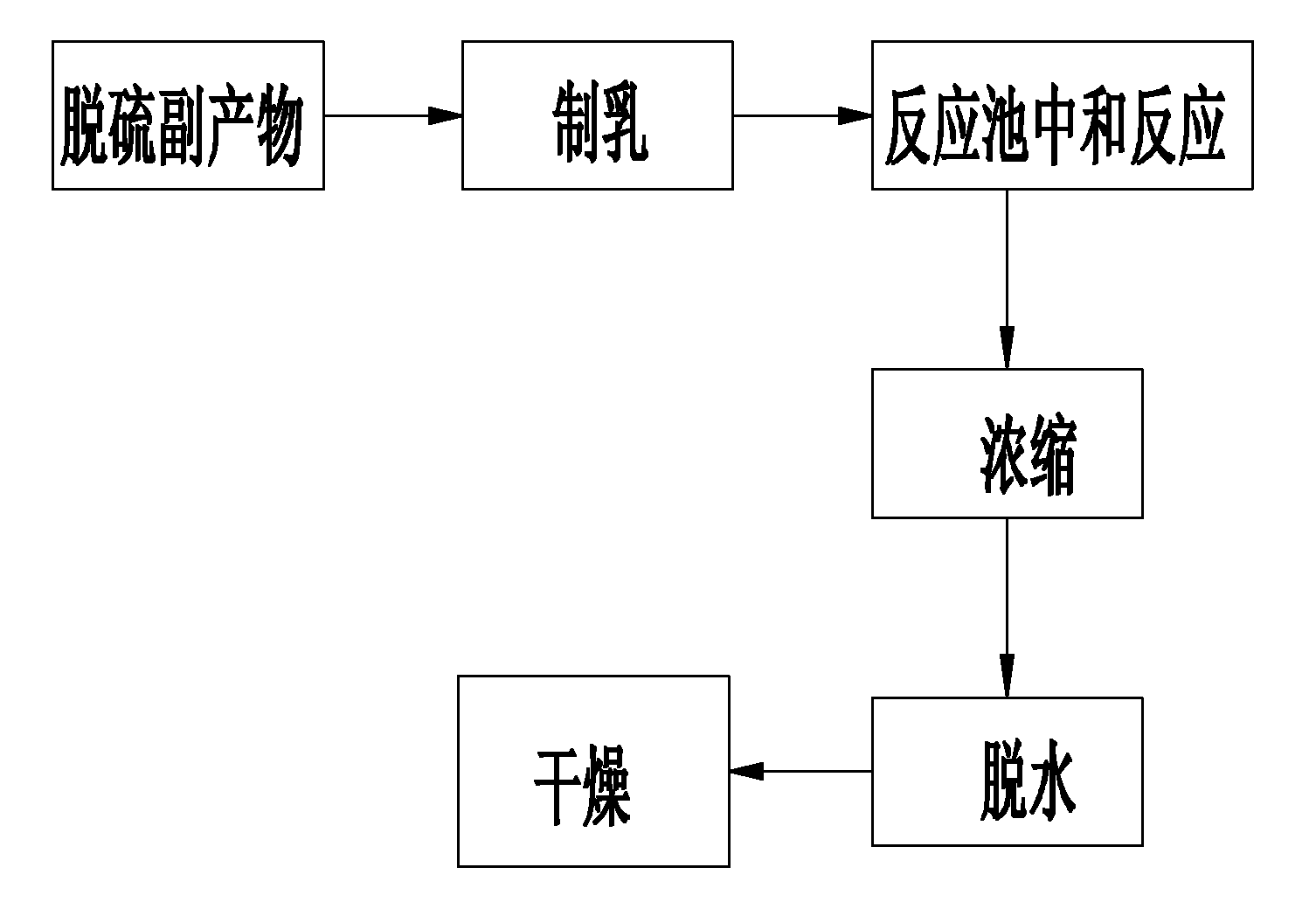

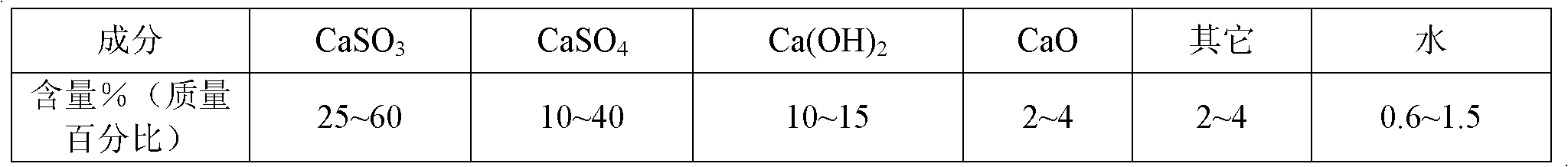

[0024] The device for preparing gypsum by semi-dry sintering flue gas desulfurization by-products is located near the waste sulfuric acid site. For the convenience of transportation, the powdered sintering flue gas desulfurization by-products are granulated into balls. like figure 1 , 2 As shown, the desulfurization by-product and quicklime are mixed according to the ratio of 4:1, and a 10% emulsion is configured in the milk making device, and then the emulsion is input into the reaction tank to react with the waste sulfuric acid solution, and the mixture is mixed in the reaction tank When the pH of the solution reaches 6.5, the mixed solution is pumped into the concentration tank to concentrate, and the waste water is discharged after concentration, and the concentrate is pumped into the dehydration device for dehydration, and after dehydration, it is dried to obtain gypsum.

Embodiment 2

[0026] The device for preparing gypsum by semi-dry sintering flue gas desulfurization by-products is located near the waste sulfuric acid site. For the convenience of transportation, the powdered sintering flue gas desulfurization by-products are granulated into balls. like figure 1 , 2 As shown, the desulfurization by-product and quicklime are mixed according to the ratio of 4:1, and configured into a 10.5% emulsion in the lime slurry milking device, and then the emulsion is input into the reaction tank to react with the waste sulfuric acid solution, and the reaction is carried out simultaneously Manual or mechanical stirring, until the pH of the mixed solution in the reaction tank reaches 7.0, pump the mixed solution into the concentration tank to concentrate, after concentration, the waste water is discharged, the concentrate is pumped into the centrifugal dehydrator for dehydration, and after dehydration, it is air-dried to obtain gypsum.

Embodiment 3

[0028] The device for preparing gypsum by semi-dry sintering flue gas desulfurization by-products is located near the waste sulfuric acid site. To prevent pollution, cement bulk trucks are used to transport powdered sintering flue gas desulfurization by-products. like figure 1 , 2 As shown, the desulfurization by-product and quicklime are mixed according to the ratio of 4:1, configured into an 11% emulsion in the lime slurry milking device, and then the emulsion is input into the reaction tank to react with the waste sulfuric acid solution, and the reaction is simultaneously used The blower is used for aeration and stirring. When the pH of the mixed solution in the reaction tank reaches 7.5, the mixed solution is pumped into the concentration tank for concentration. After concentration, the waste water is discharged. The concentrate is pumped into the centrifugal dehydrator for dehydration, and after dehydration, it is air-dried to obtain gypsum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com