Two-stage hydrocarbon hydrogenation method for cracking different fractions of generated oil at refining stage in branches

A technology of oil generation and hydrogenation oil generation, which is applied in the field of two-stage hydrogenation of hydrocarbons in which different fractions of oil produced in the refining section are cracked separately, and can solve the problems of reduced diesel yield, high catalyst cracking activity, and low catalyst space velocity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

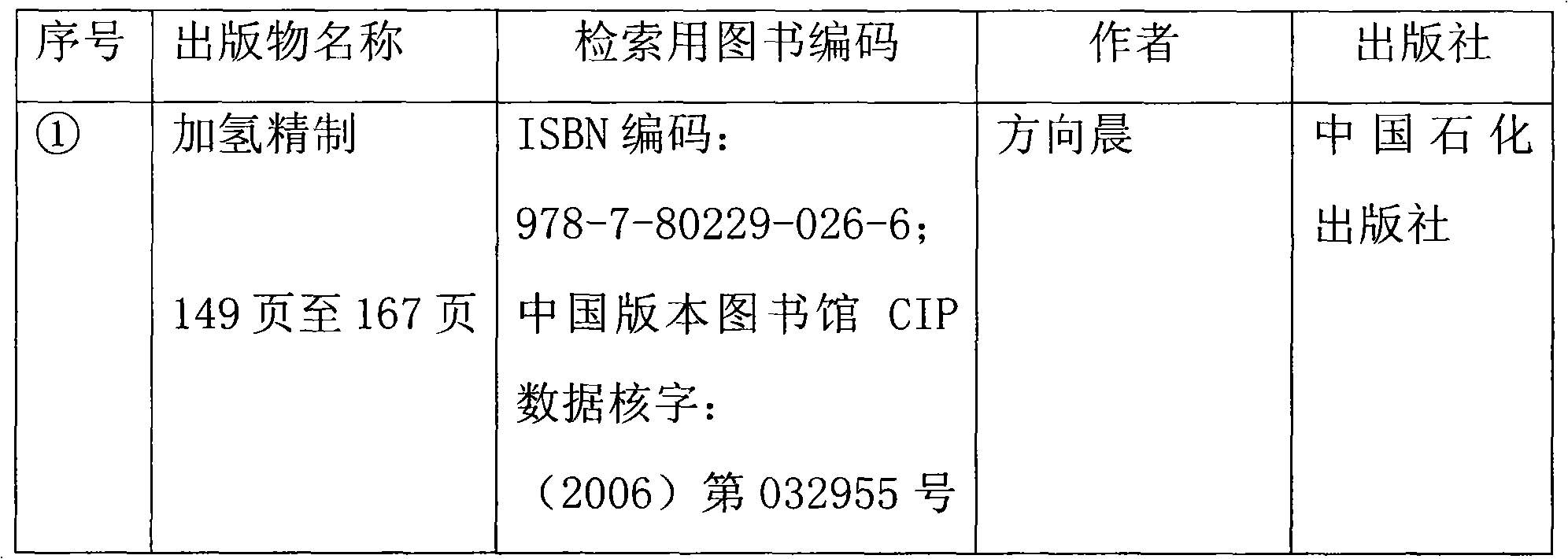

Image

Examples

Embodiment 1

[0225] A medium-temperature coal tar with a processing capacity of 50t / h, the yield of components (cetane number 28) in the oil produced by one-stage hydrofining with a conventional boiling point between 200 and 310°C is 36%, and the conventional boiling point is between 310 The yield of ~520 ℃ component is 31%, adopts flow process of the present invention to carry out and use selective hydrogenation ring-opening dearomatization method to improve the cetane number of hydrogenated refined diesel oil component (raised to 33), has completed wax simultaneously The task of producing diesel oil through hydrocracking and full conversion of oil components has achieved the purpose of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com