Equipment failure early-warning system and method

A technology of equipment failure and early warning system, applied in measuring devices, instruments, measuring electricity and other directions, can solve problems such as equipment damage and aggravation of failure degree, and achieve the effect of eliminating sudden production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

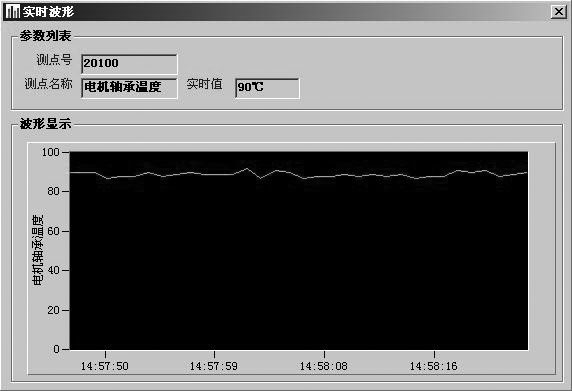

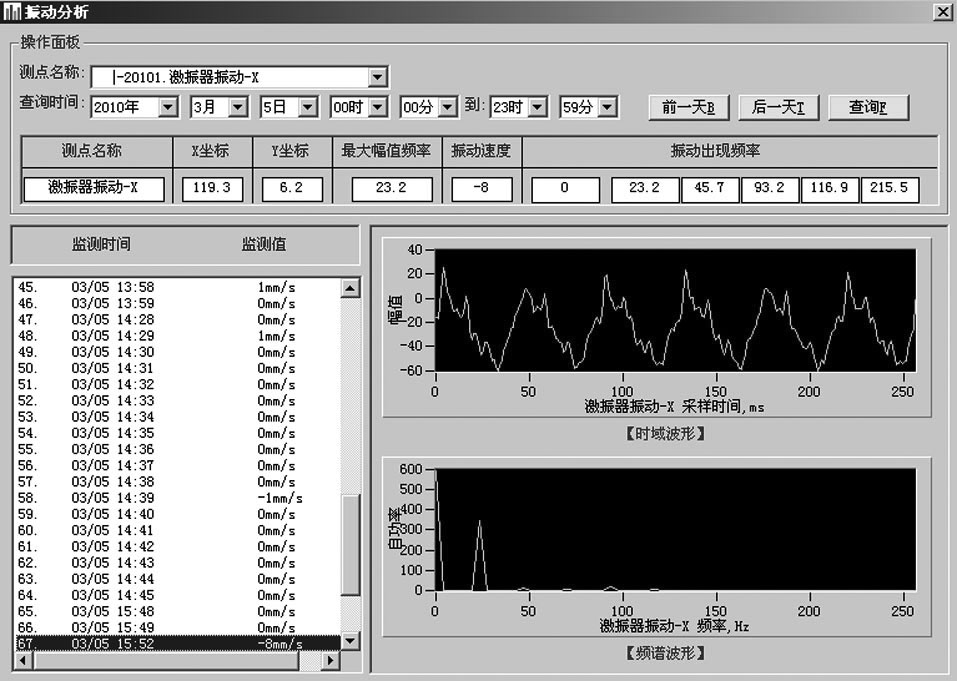

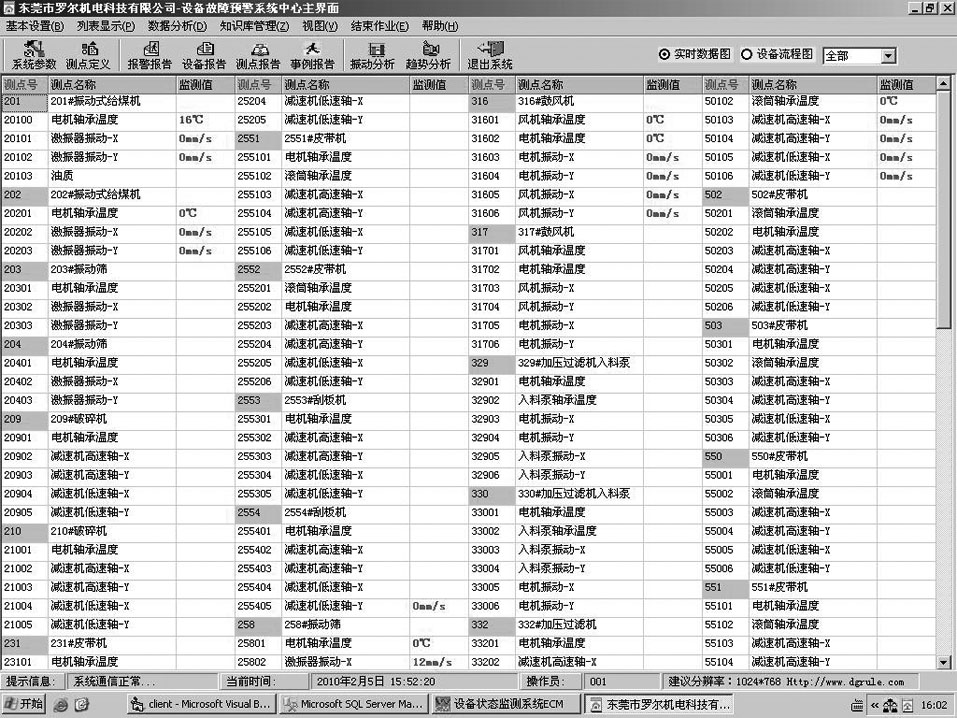

[0038] according to figure 1 The architecture of the equipment fault early warning system is shown, and different types of sensors such as current, voltage, temperature, displacement, speed, acceleration, pressure, etc. are installed in the appropriate parts of the monitored equipment. These sensors output 4mA~20mA or 0V~ 5V analog signal, connect the sensor output end and the corresponding input end of the signal acquisition module with a shielded cable to realize the online acquisition of the parameters of the detected equipment.

[0039] The data acquisition module performs analog-to-digital conversion on the acquired analog signals, selects the appropriate acquisition rate and AD accuracy according to the changing characteristics of the acquired parameters, and selects various types of bus, wireless, Ethernet, etc. The network architecture transmits the data to the data processing modules.

[0040] Both the data processing module and the self-learning intelligent early war...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com