Optical lens with dustproof and vacuum pumping function

A vacuum exhaust and optical lens technology, applied in optics, optical components, installation, etc., can solve the problems of no dustproof effect, reduced performance of the optical system, and impact on equipment accuracy, etc., and achieves simple structure and meets the requirements of vacuum exhaust , easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

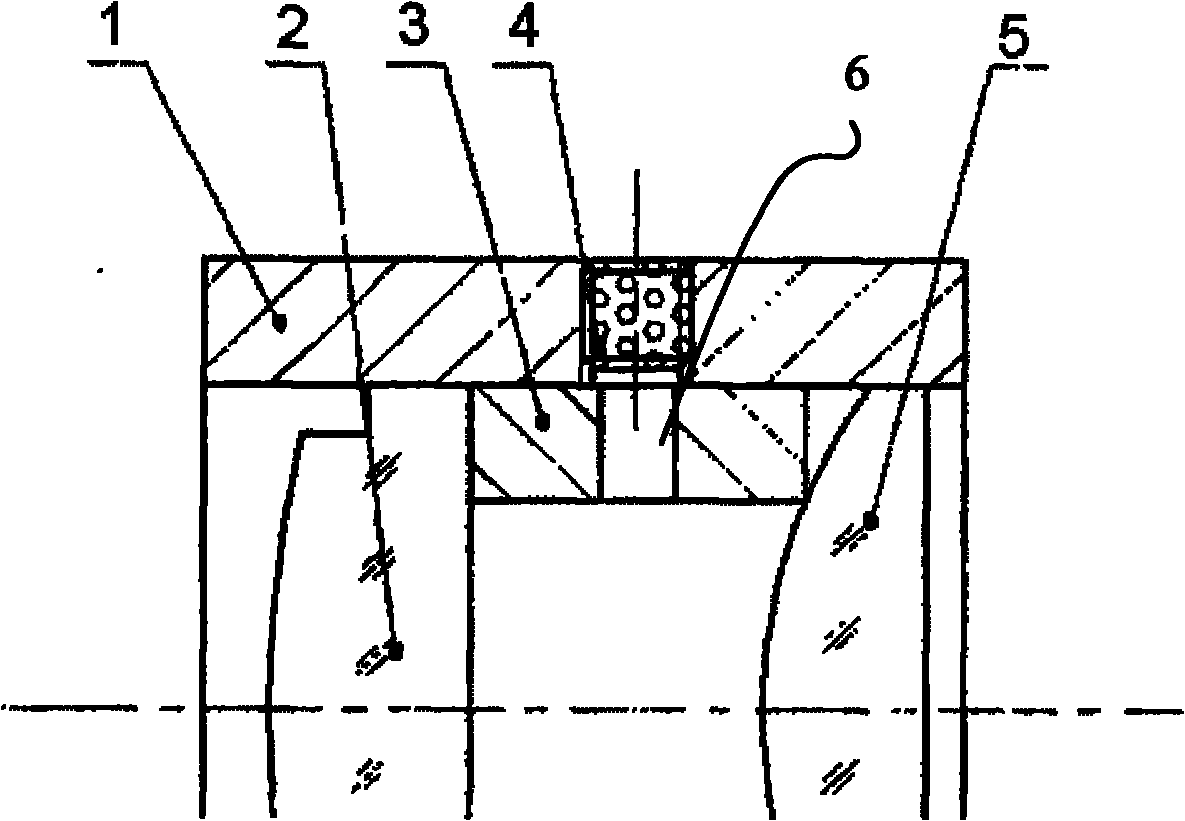

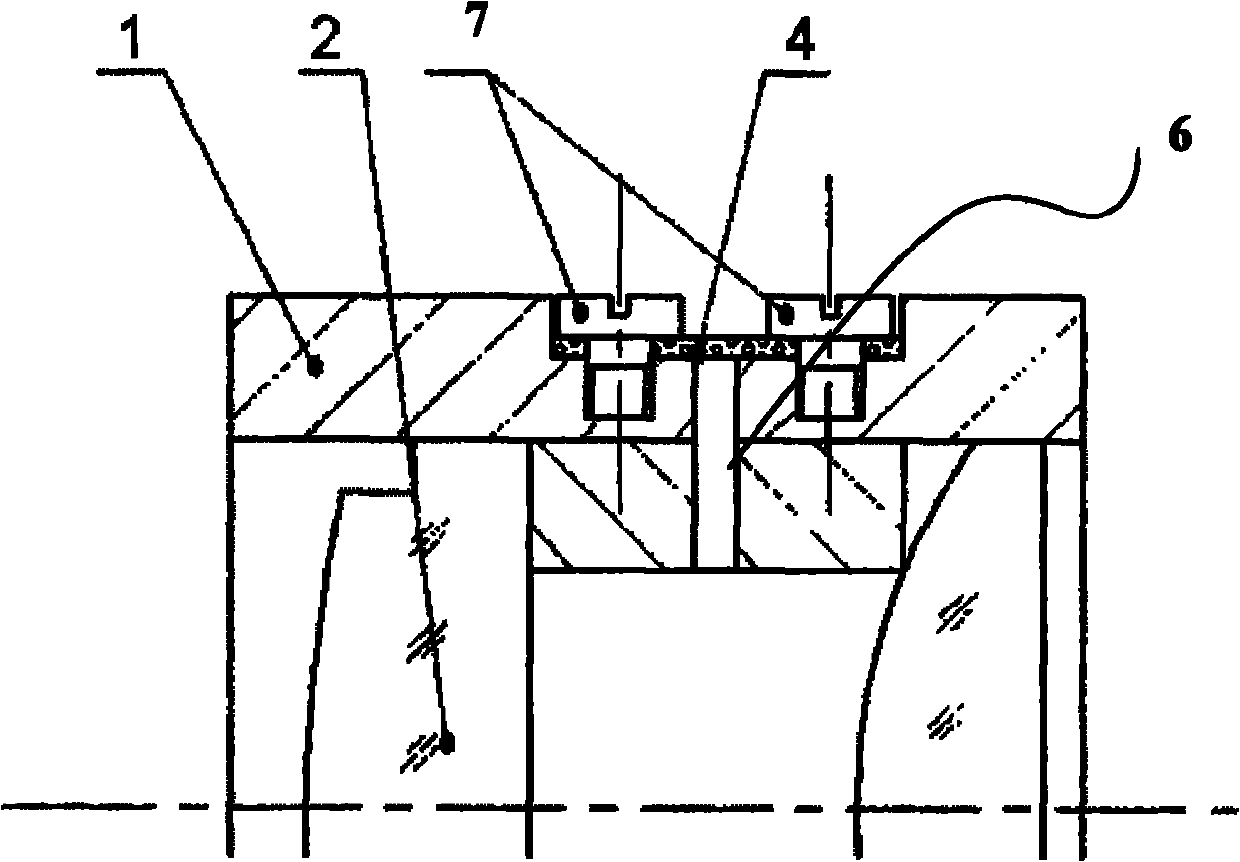

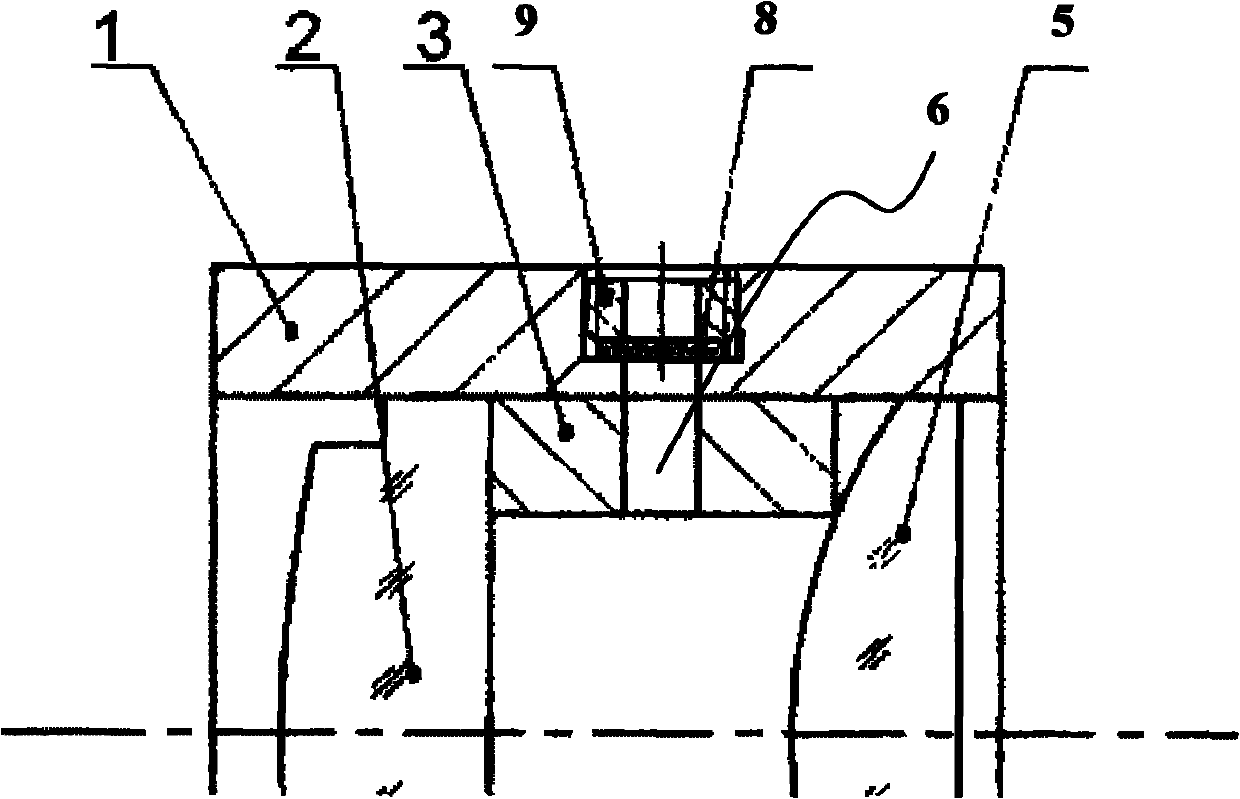

[0017] The invention provides an optical lens with dustproof and vacuum exhaust functions, which includes a lens barrel and an exhaust hole arranged on the wall of the lens barrel, and the device also includes a microporous material made of a microporous material arranged on the exhaust hole. Complete dustproof parts. The dust-proof parts are dust-proof nails suitable for the aperture of the vent hole, dust-proof covers arranged outside the vent hole, or dust-proof rings, dust-proof mats or dust-proof pads arranged on the inner wall of the lens barrel corresponding to the positions of the vent holes. dust circle. The material used in the present invention is a microporous material. A microporous material refers to a large number of open or closed tiny pores inside or on the surface of the material. Porous metal material, can choose the microporous material of corresponding pore diameter according to the diameter of dust particle, the pore diameter of microporous material shou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com