External cavity semiconductor laser

A semiconductor and laser technology, applied in the direction of semiconductor lasers, lasers, laser parts, etc., can solve the problems of small continuous non-mode-hopping laser frequency tuning range, etc., and achieve the effect of easy tuning and control, and frequency stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

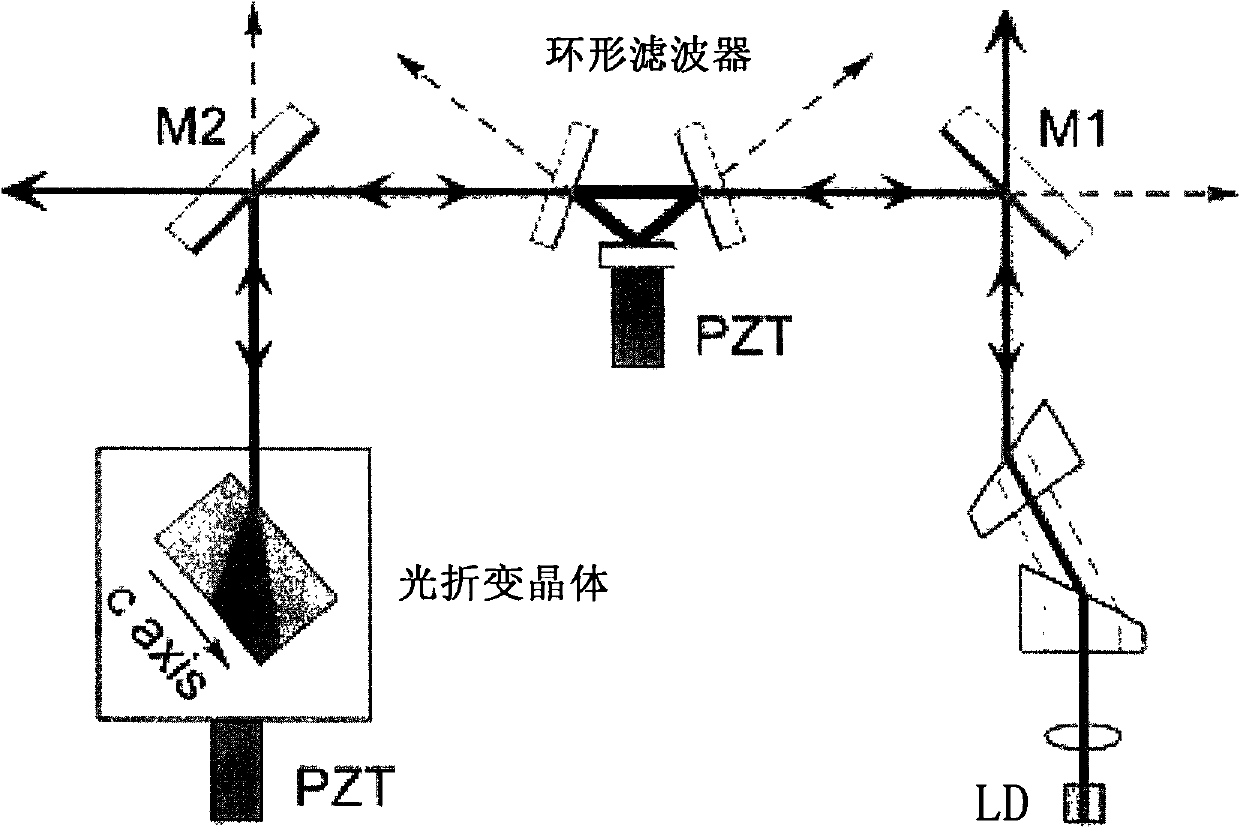

[0037] The external cavity semiconductor laser of the present invention mainly includes: a semiconductor laser tube (LD) 1, a collimator lens 3, a photorefractive crystal 14 and a monolithic annular F-P cavity (MFC) 5.

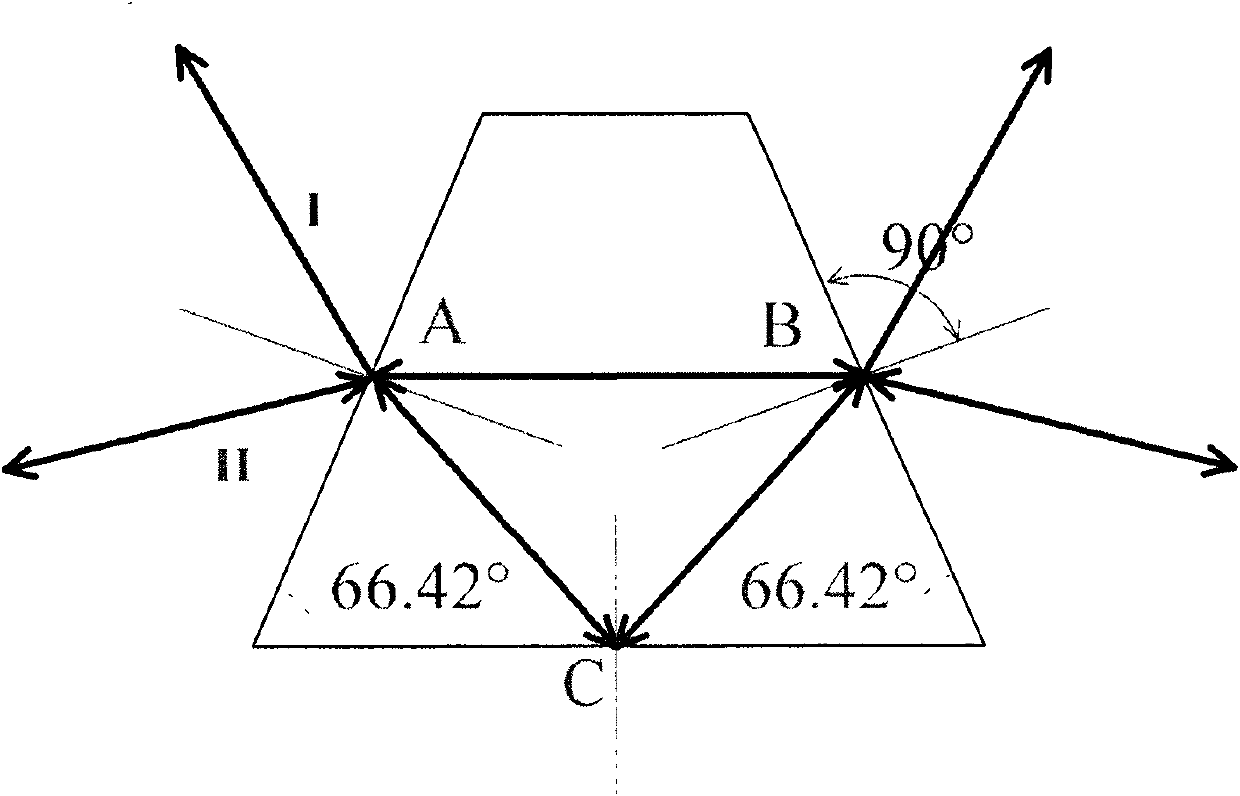

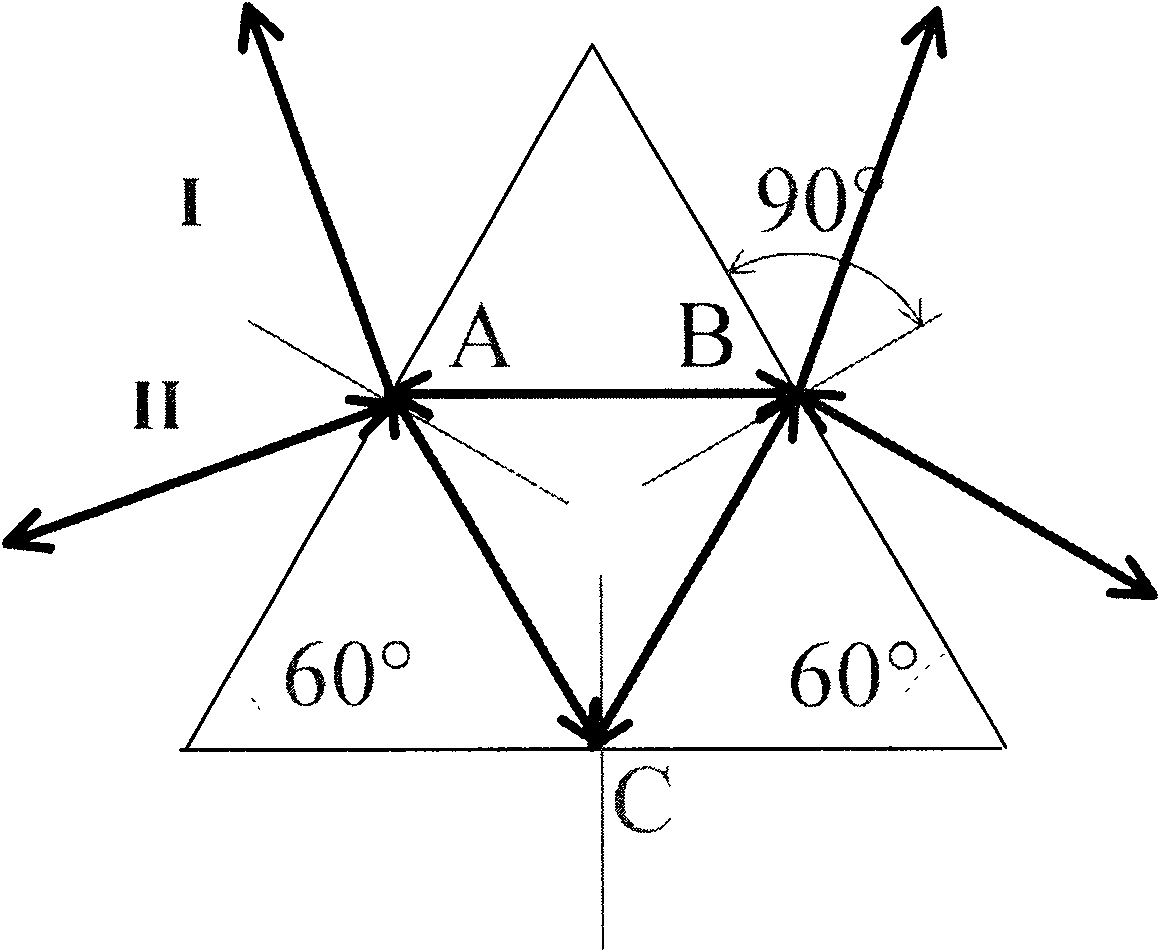

[0038] An example of the present invention is Figure 5 As shown, the light emitted by LD1 is collimated by the collimating lens 3, then passes through the half-wave plate (HW) 501, and the point A on the light input surface enters the single ring F-P cavity 5, and passes through the reflection plate coated with a high reflection film. After being reflected at point B on the surface, it goes to point C, and returns to point A after being totally reflected by the plane where point C is located, forming an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com