Air-cooled converter power module system

An air-cooled converter and power module technology, which is used in output power conversion devices, cooling/ventilation/heating renovation, electrical components, etc. Fan failure has a greater impact, to eliminate the capacitor failure problem, large ripple current, and enhance scalability and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

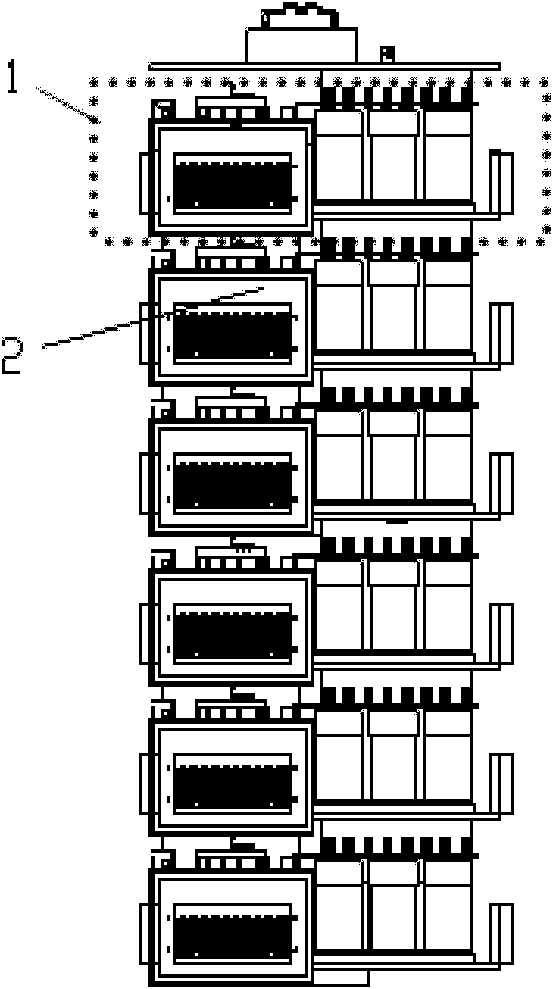

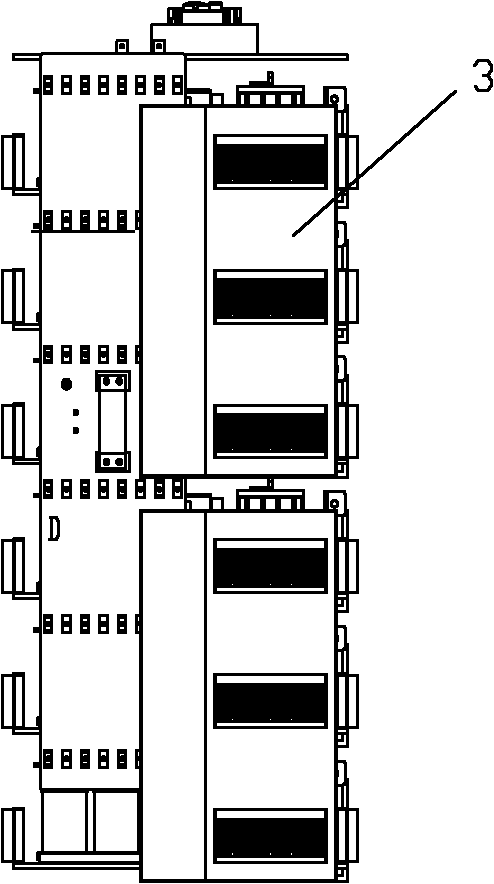

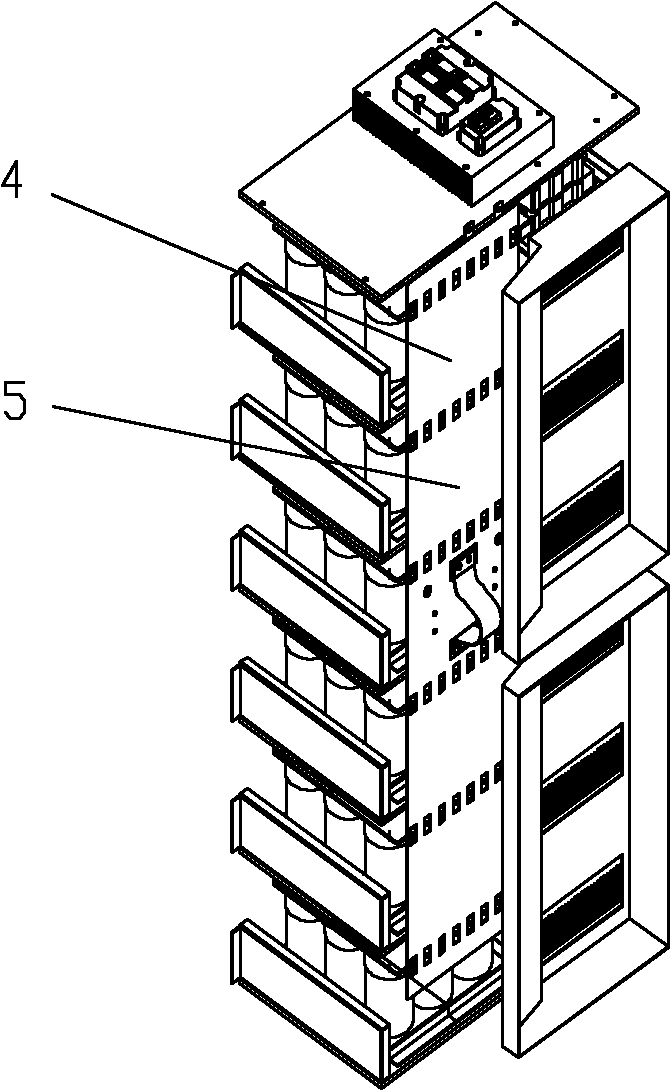

[0014] The present invention adopts a single bridge arm power module parallel structure, with figure 1 Shown is the parallel connection of six single-arm power modules (1) from top to bottom. Such as image 3 As shown, all modules are connected in parallel through the system positive DC busbar (4) and the system negative DC busbar (5) to realize integrated installation. The air ducts of each power module are placed in parallel, and the installation distance of the front and rear air ducts (2) (3) is consistent with the distance between the front and rear doors, forming an air duct independent of the space in the cabinet. The centrifugal fan behind the cabinet forms a front-to-back draft with The calorific value of the module when the converter is running.

[0015] Each single-arm power module includes an IGBT module (6) with an air-cooled radiator, an AC busbar (7), an absorbing non-inductive capacitor (8), a module positive DC busbar (9), and a module negative DC busbar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com