Quality event trigger determining method and device for continuous casting machine

A technology for event triggering and determining methods, which is applied in the field of metallurgy, and can solve problems such as trigger rules not meeting casting machine conditions, quality event trigger rules failing to meet new requirements, and failure to correctly monitor continuous casting machine abnormalities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the following description, for illustrative purposes, many specific details are set forth in order to provide a comprehensive understanding of one or more embodiments. However, it is obvious that these embodiments can also be implemented without these specific details. In other examples, for the convenience of describing one or more embodiments, well-known structures and devices are shown in the form of block diagrams.

[0026] Hereinafter, various embodiments according to the present invention will be described in detail with reference to the accompanying drawings.

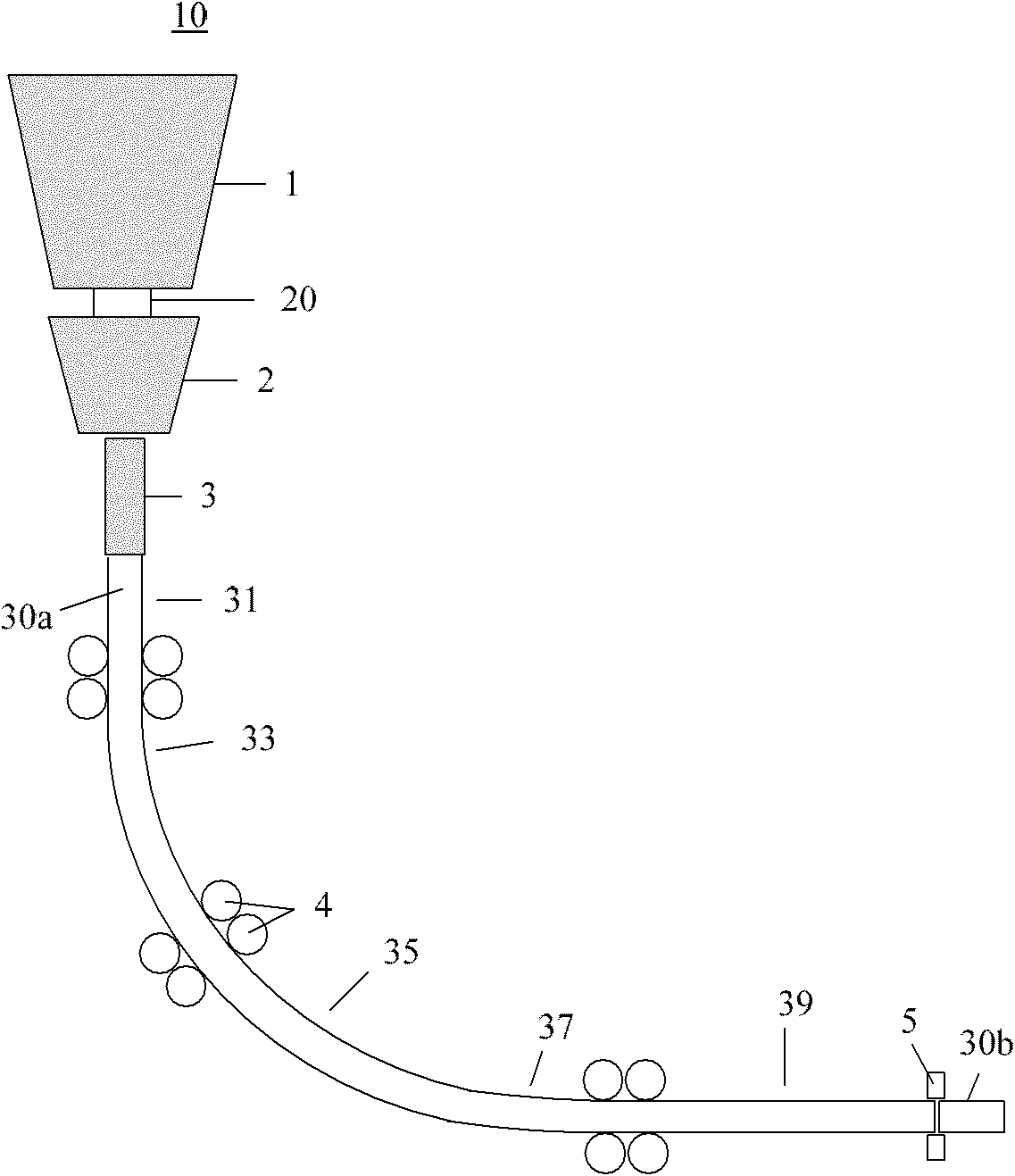

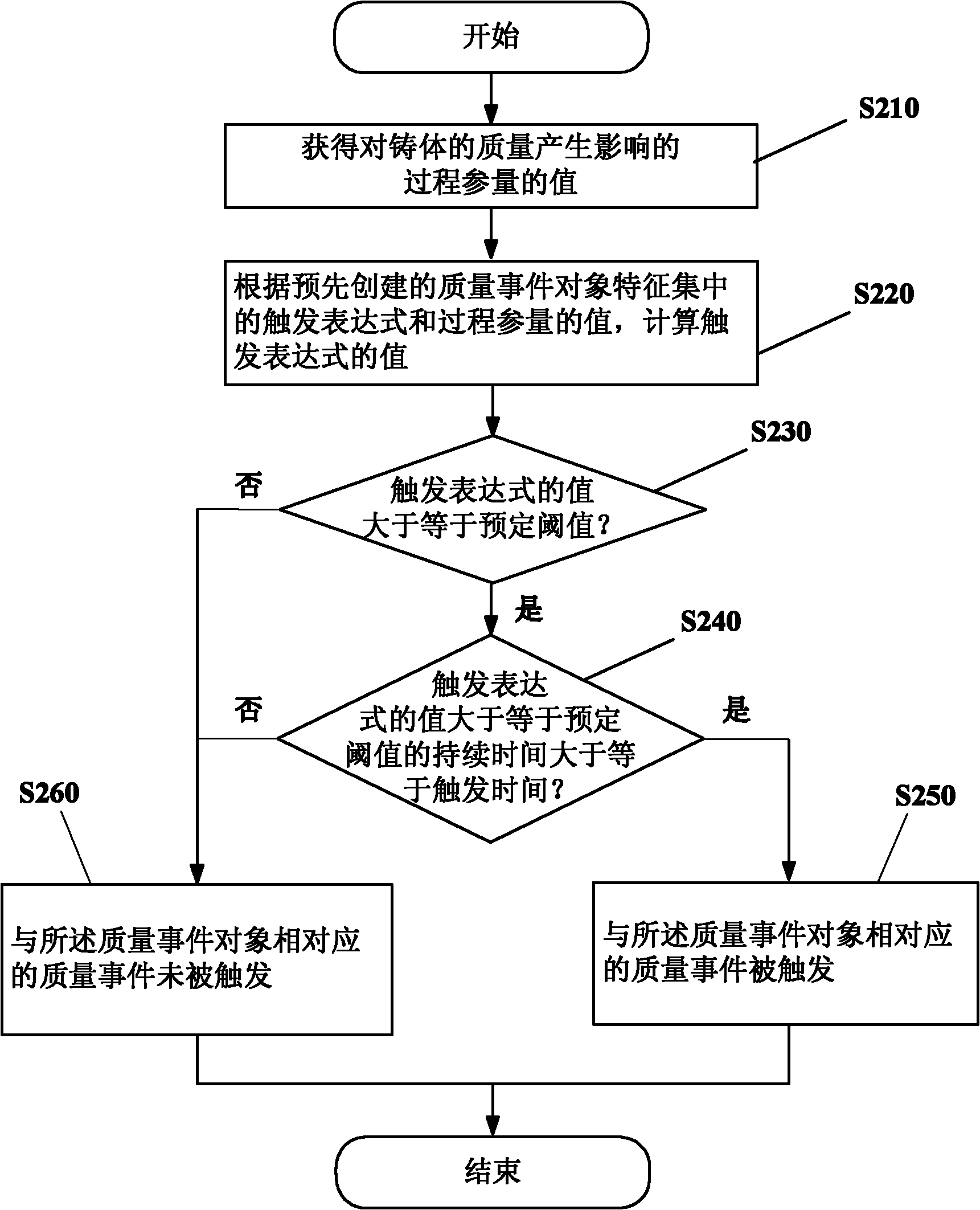

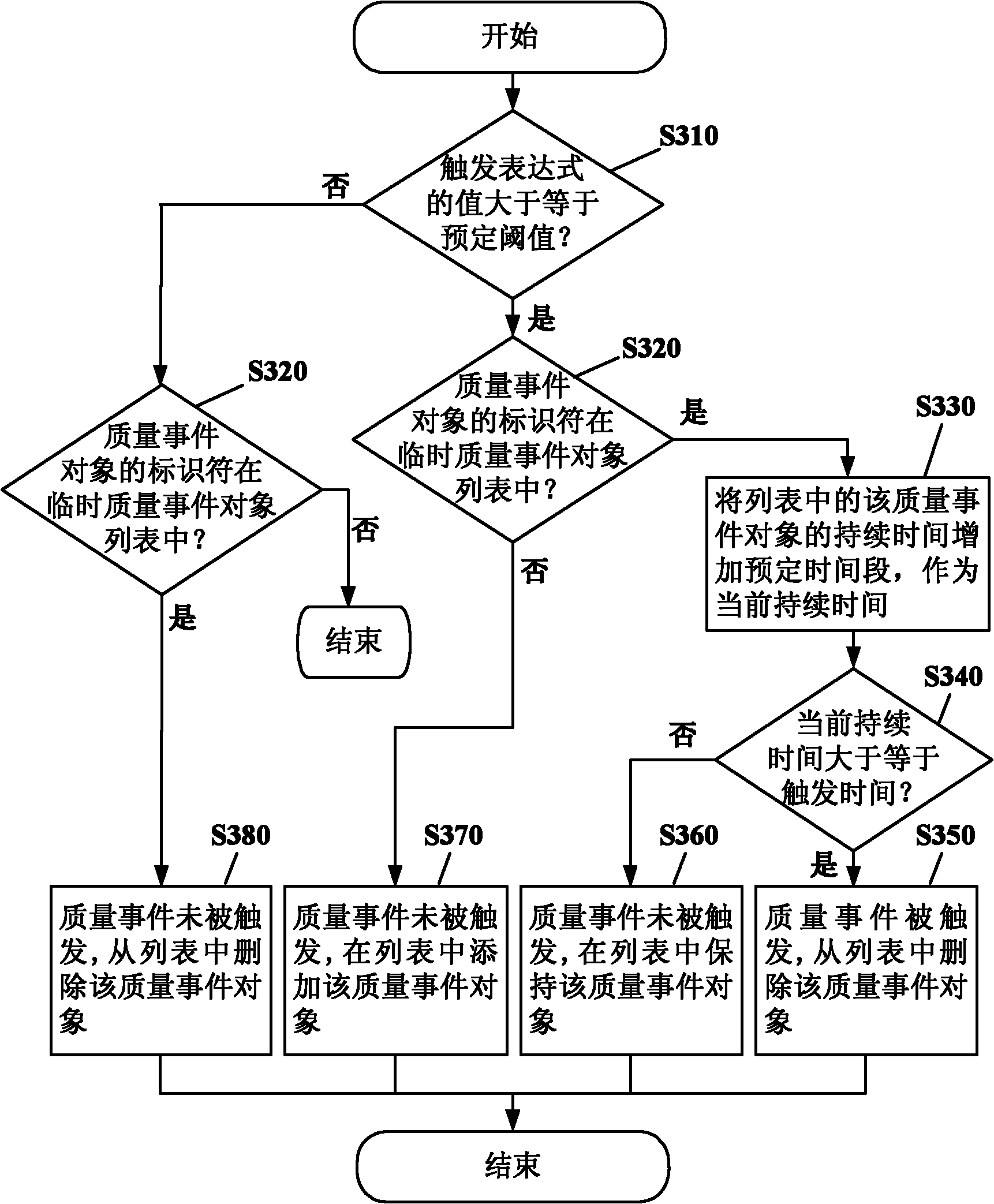

[0027] Before performing the quality event trigger determination method for a continuous casting machine according to the present invention, it is first necessary to create a quality event object for generating a quality event according to the process parameters that affect the quality of the casting body. It is described by a feature set including at least a trigger expression, and the trigger expression i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com