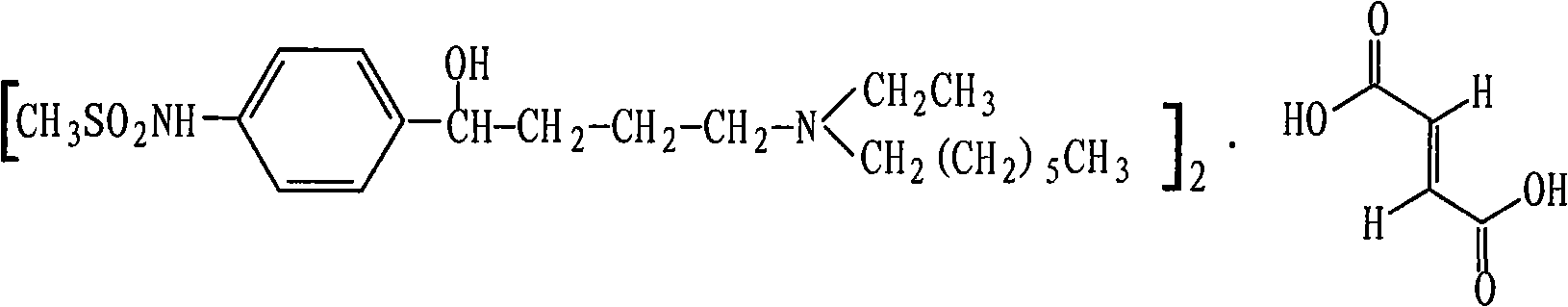

Refining method of ibutilide fumarate

A technology of ibutilide fumarate and a purification method, applied in the field of medicine, can solve problems such as inability to achieve effective purification, and achieve the effects of reducing the number of times, simple process operations, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 10g crude ibutilide fumarate with a purity of 96.8% by HPLC into a three-necked reaction flask equipped with a stirring and reflux condenser, add 100ml of acetone, stir and heat to reflux, and add 0.5g activated carbon to decolorize for 20min after it is completely dissolved. Filtration; Slowly add 100ml of ether to the filtrate kept under reflux, stir vigorously, cool to 5℃ and let stand; separate the supernatant; add 100ml of acetone to the residue after heating to dissolve, cool to 5℃ to crystallize, filter Ibutilide fumarate can be obtained by drying under reduced pressure at 50°C. After drying, 8.7 g of the product was obtained, the yield was 87.0%, and the HPLC purity was 99.9%.

Embodiment 2

[0022] Add 10g of crude ibutilide fumarate with a HPLC purity of 96.8% into a three-necked reaction flask equipped with a stirring and reflux condenser, add 120ml of dichloromethane, stir and heat to reflux, and add 0.5g of activated carbon to decolorize for 20min after it is completely dissolved. Filter while it is hot; slowly add 120ml of ether to the filtrate kept under reflux, stir vigorously, cool to 5℃ and let stand; separate the supernatant; add 100ml of acetone to the residue after heating to dissolve, then cool to 5℃ to crystallize , Filtered, dried under reduced pressure at 50°C to obtain ibutilide fumarate. After drying, 8.1 g of the product was obtained, the yield was 81.0%, and the HPLC purity was 99.7%.

Embodiment 3

[0024] Add 10g crude ibutilide fumarate with a HPLC purity of 95.6% to a three-necked reaction flask equipped with a stirring and reflux condenser, add 120ml of acetone, stir and heat to reflux, and add 1g of activated carbon to decolorize for 30min after it is completely dissolved, and filter while hot ; Slowly add 200ml of ether to the filtrate kept under reflux, stir vigorously, cool to 5 ℃ and stand still; separate the supernatant; add 120ml of acetone to the residue after heating to dissolve, cool to 5 ℃ to crystallize, filter, Ibutilide fumarate is obtained by drying under reduced pressure at 50°C. After drying, 8.3 g of the product was obtained, the yield was 83.0%, and the HPLC purity was 99.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com