Conductive paste and method of manufacturing printed circuit board using the same

A technology of conductive adhesive and conductive powder, applied in the directions of printed circuit, printed circuit, printed circuit manufacturing, etc., can solve the problems of bump breakage, increase of interlayer insulation distance, and inability to ensure interlayer insulation distance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Functions, effects, and technical configurations of a conductive paste and a method of manufacturing a printed circuit board using the same according to the present invention will be clearly understood through the following detailed description with reference to the accompanying drawings showing preferred embodiments of the present invention.

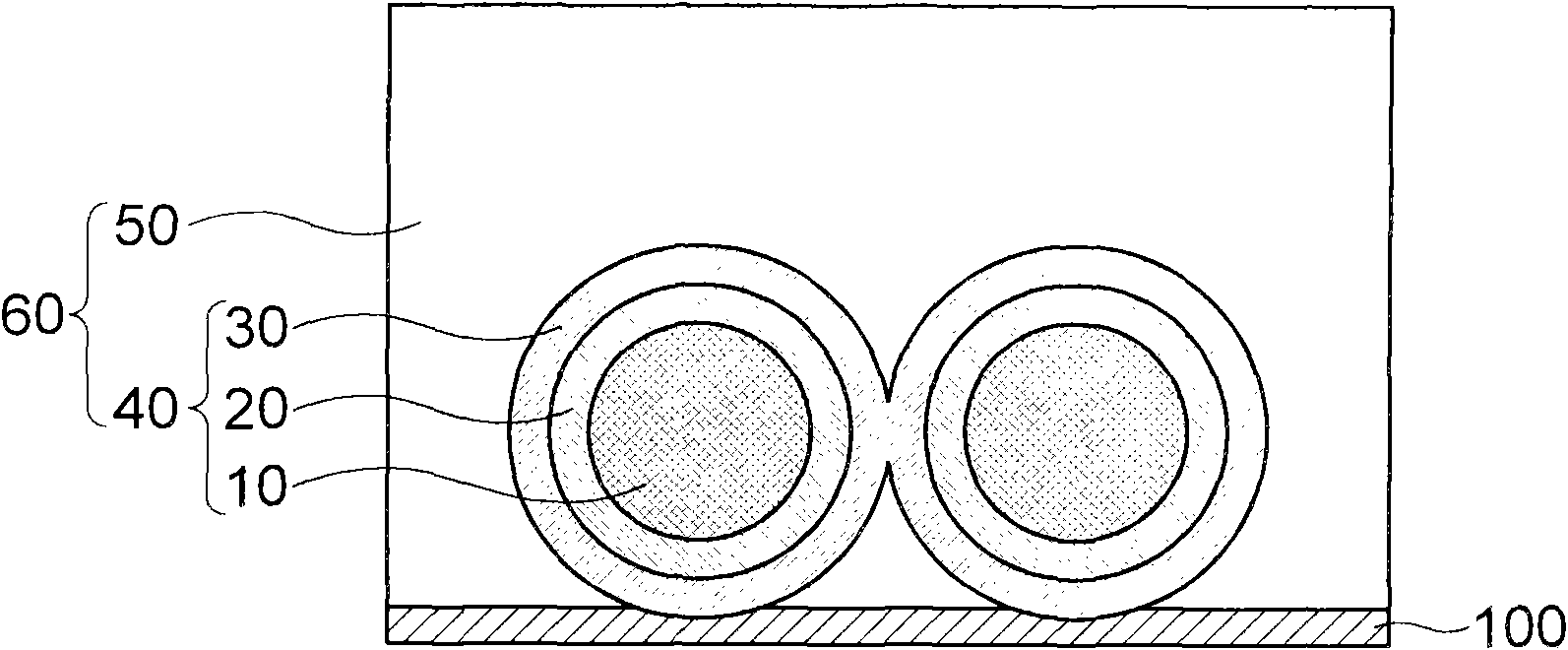

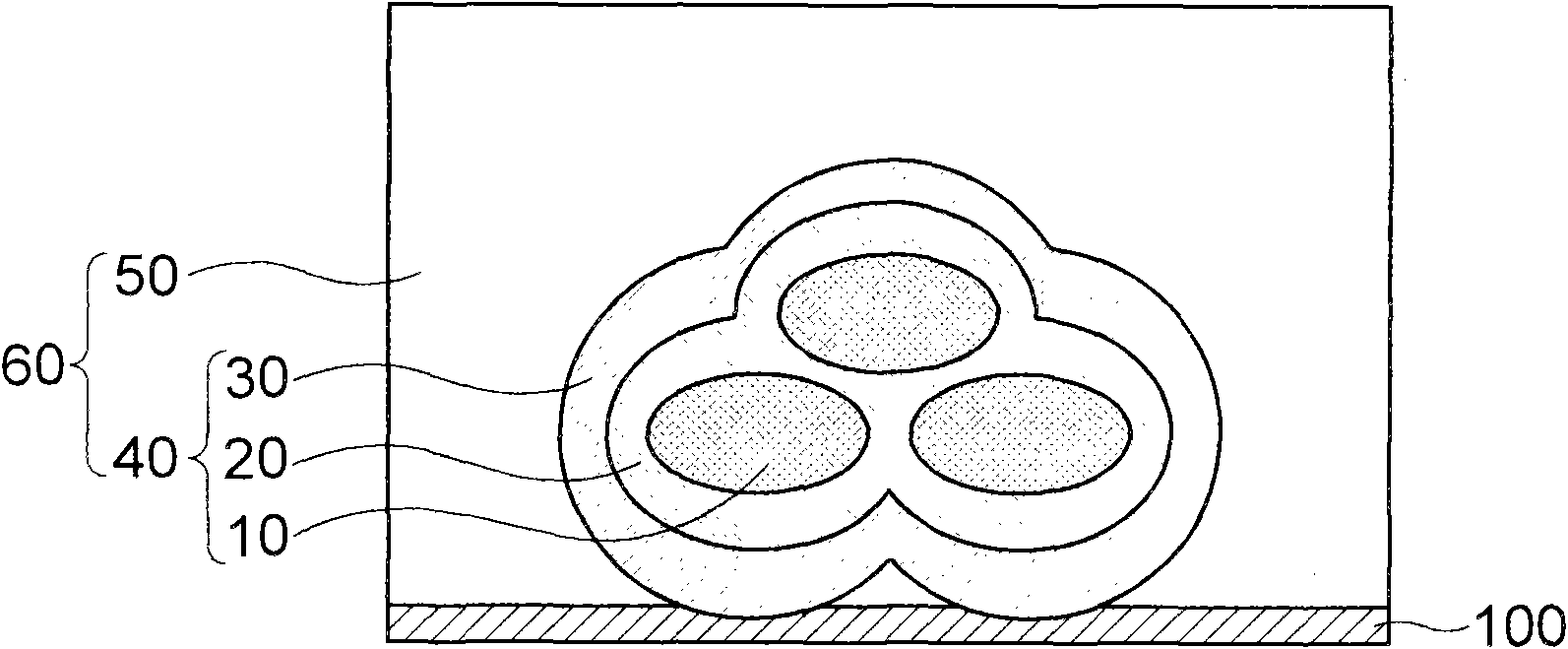

[0045] In the following, reference will be made to Figure 1 to Figure 6 A conductive adhesive and a method of manufacturing a printed circuit board using the conductive adhesive according to an embodiment of the present invention will be described in detail.

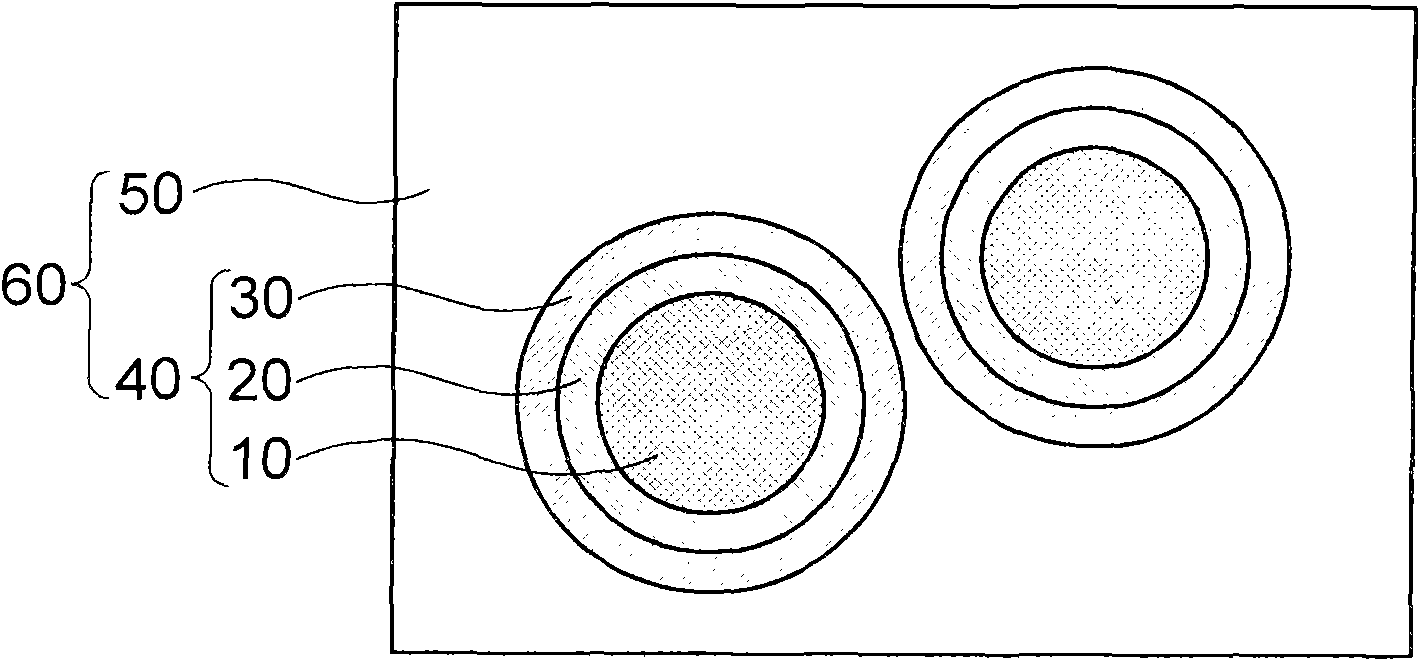

[0046] first, figure 1 is a diagram schematically showing a conductive paste according to an embodiment of the present invention.

[0047] like figure 1 As shown, the conductive adhesive 60 according to the embodiment of the present invention includes: conductive powder 40, having a polymer powder 10 and a first low-melting-point metal 20 and a second metal with differen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com