Big-tonnage cantilever type horizontal tuned mass damper for regulating eddy-current damping

A technology of tuning mass damping and eddy current damping, which is applied to bridges, bridge parts, bridge construction, etc., can solve the problems of difficult adjustment of frequency and damping parameters, achieve high durability and reliability, simplify structure and manufacturing process, and improve The effect of the ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

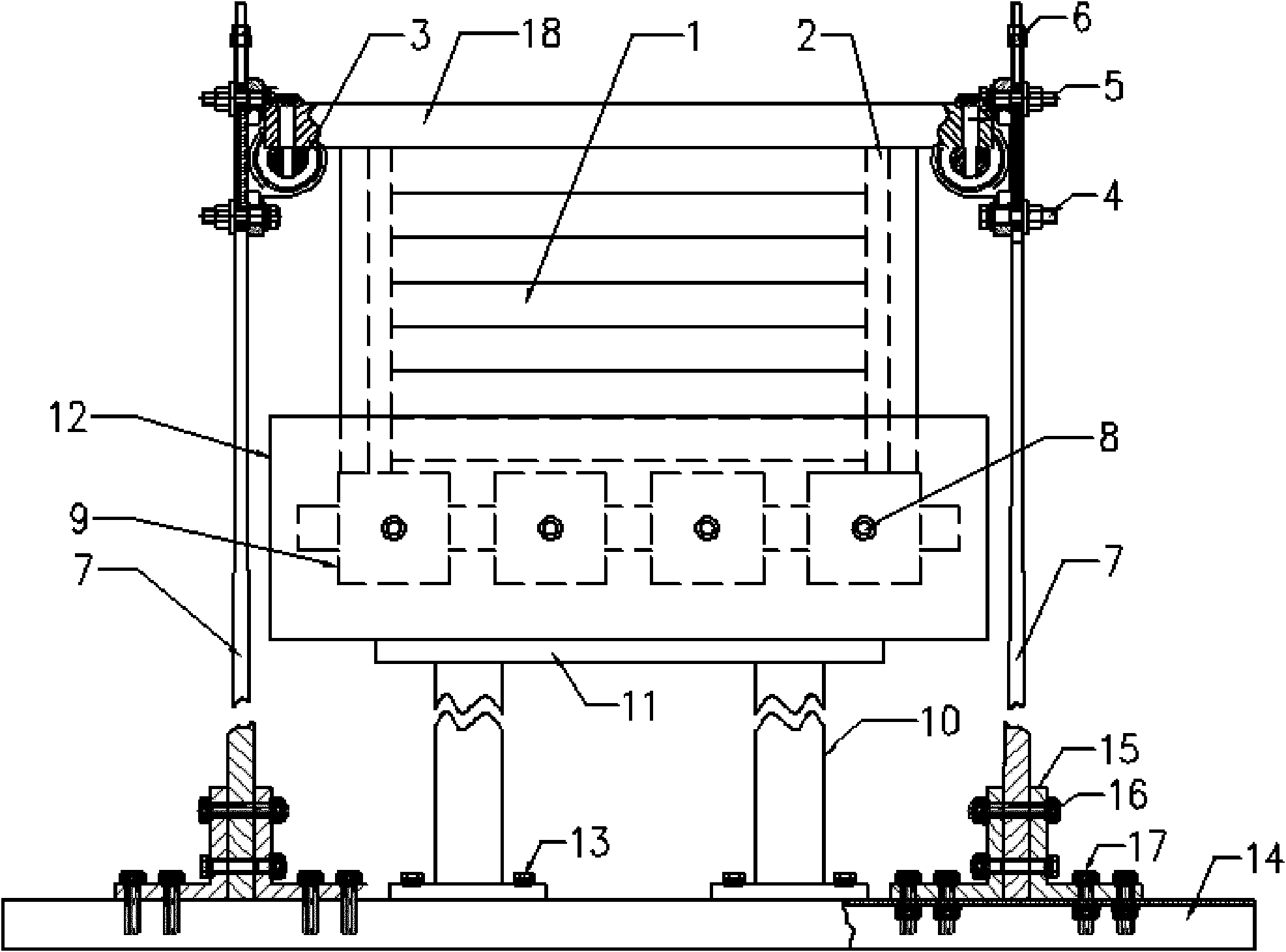

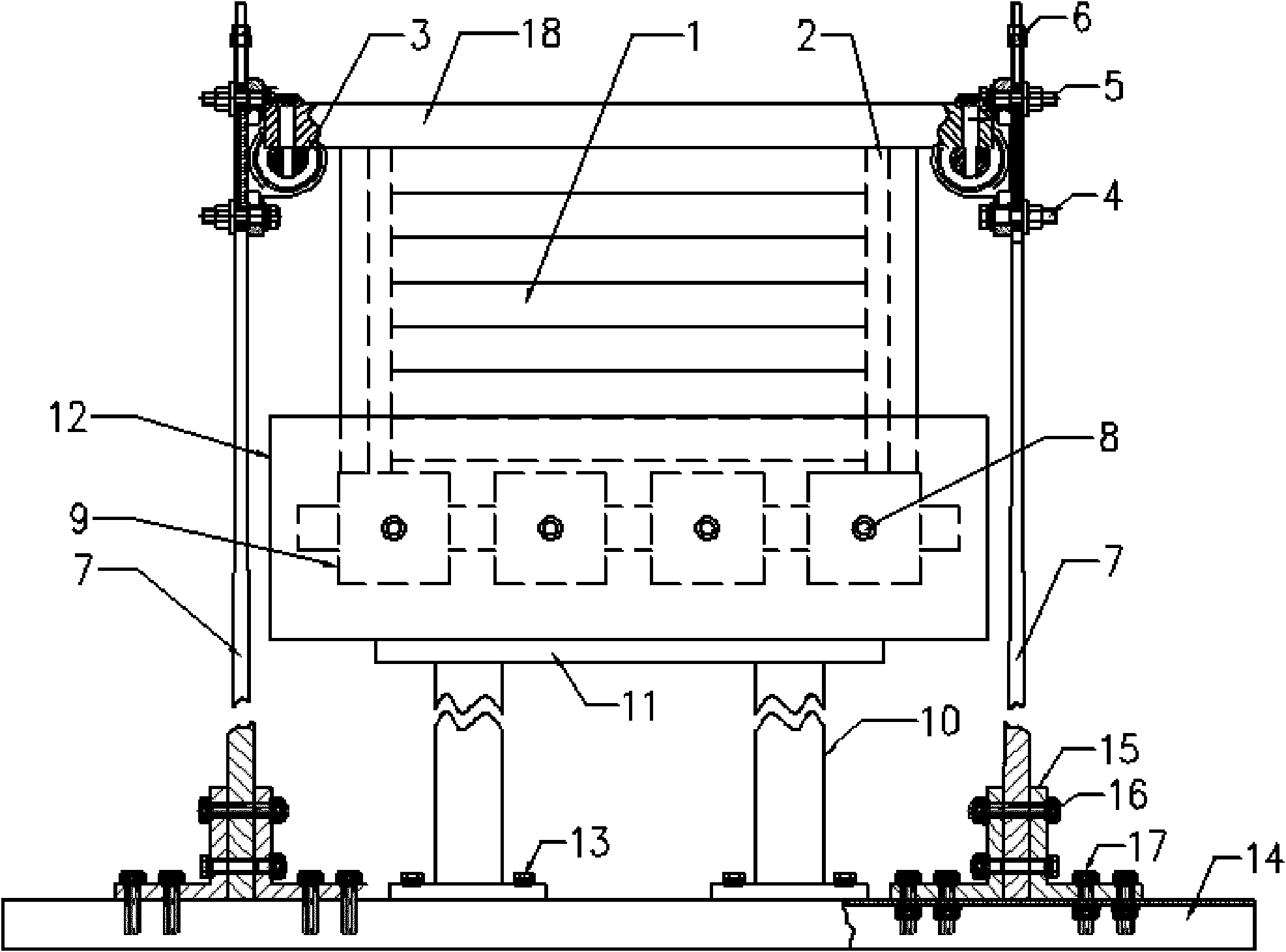

[0026] Such as figure 1 As shown, the large-tonnage horizontal cantilever type eddy current tuned mass damper of the present invention includes an equal-strength cantilever beam composed of two side pillars 7 and a crossbeam 18. 7. The bottom end is fixed on the base 14; its structural feature is that the upper end of the mass block 1 is connected with the beam 18, and the lower end of the mass block 1 is equipped with a rectangular permanent magnet 9; The copper plate 12 installed on the base 14 has a gap between the copper plate 12 and the rectangular permanent magnet 9 .

[0027] The base 14 is made of channel steel.

[0028] Such as figure 1 , a composition of the beam height adjustment mechanism is that the end of the beam 18 is mounted on the ball bearing 3 with a seat, the seat of the ball bearing 3 with a seat is mounted on the pillar, and the screw rod 6 is adjusted by the height of the support point of the beam. Adjust the installation position of the ball bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com