Steel frame template and assembly method thereof

A formwork and steel frame technology, applied in the field of steel frame formwork and its assembly, can solve the problems of panel damage, inconvenient disassembly and assembly of formwork, inability to protect plywood panels, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Describe the embodiment of the present invention in detail below in conjunction with accompanying drawing; It should be noted that, this embodiment is descriptive,

[0037] It is not restrictive, and the protection scope of the present invention cannot be limited by this.

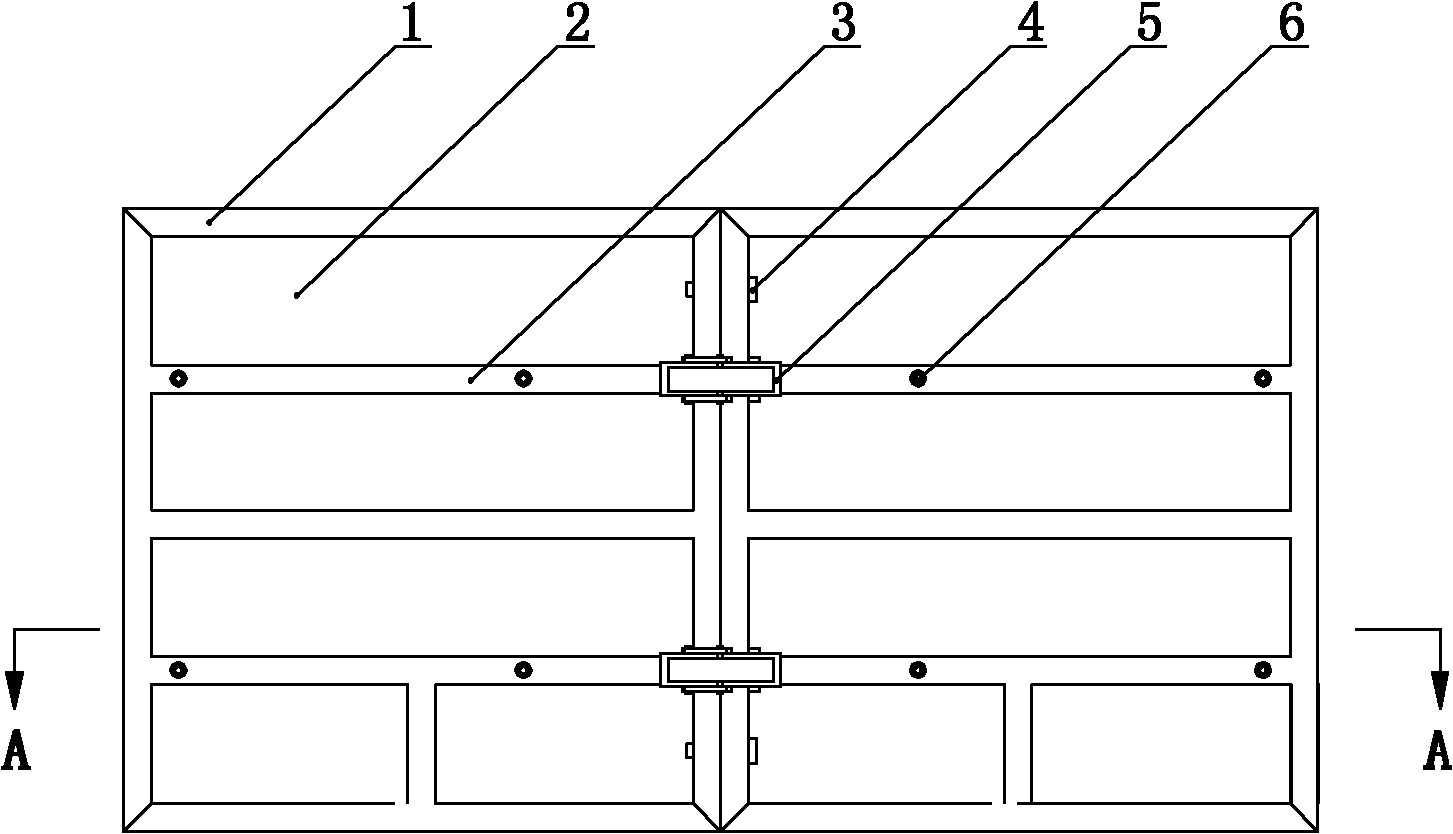

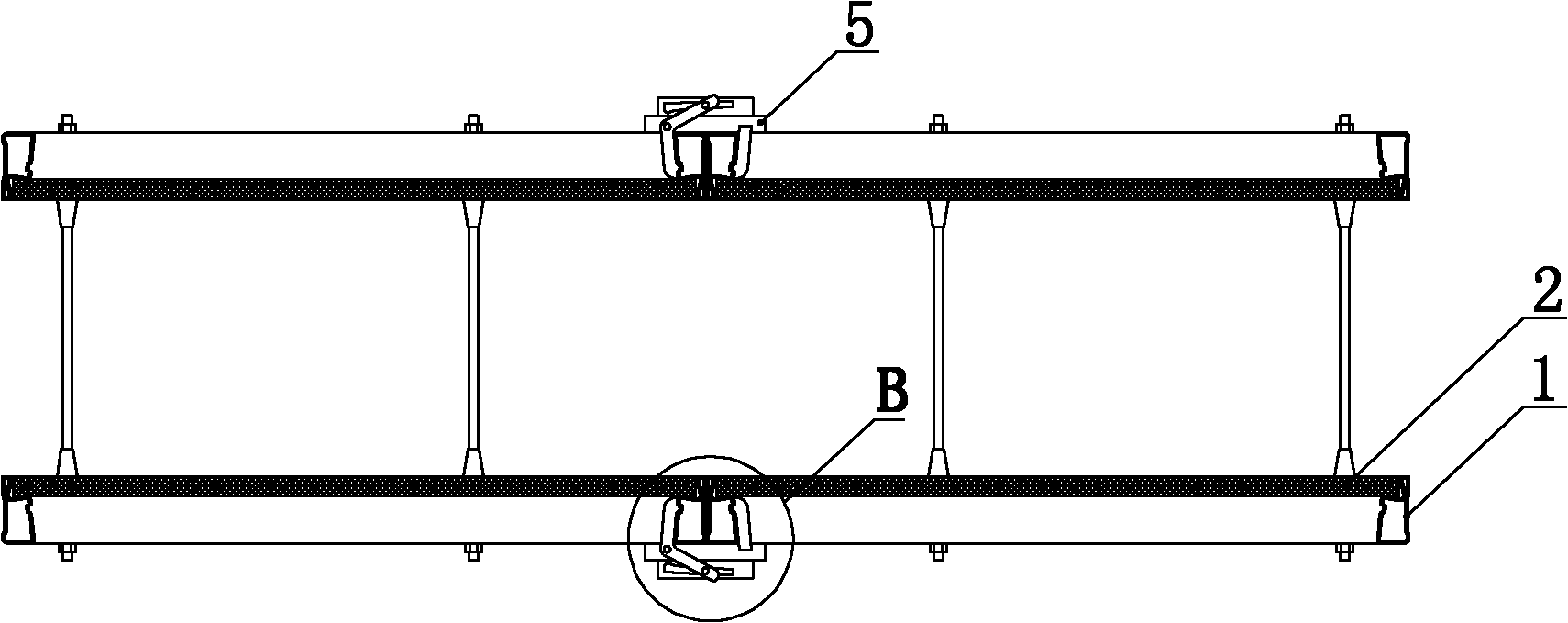

[0038] A steel frame formwork such as figure 1 As shown, it includes a steel frame 1 and a panel 2 fixedly installed on the frame. The material of the steel frame in this embodiment is Q235. The panel is a rectangle or a rectangular panel, and what the panel adopts in this embodiment is a film-coated plywood panel.

[0039] Strengthening ribs 3 are arranged between the outer frames of the panels, and pull bolt holes are arranged on the film-coated plywood panels and on the corresponding reinforcing ribs.

[0040] The innovation point of the present invention is:

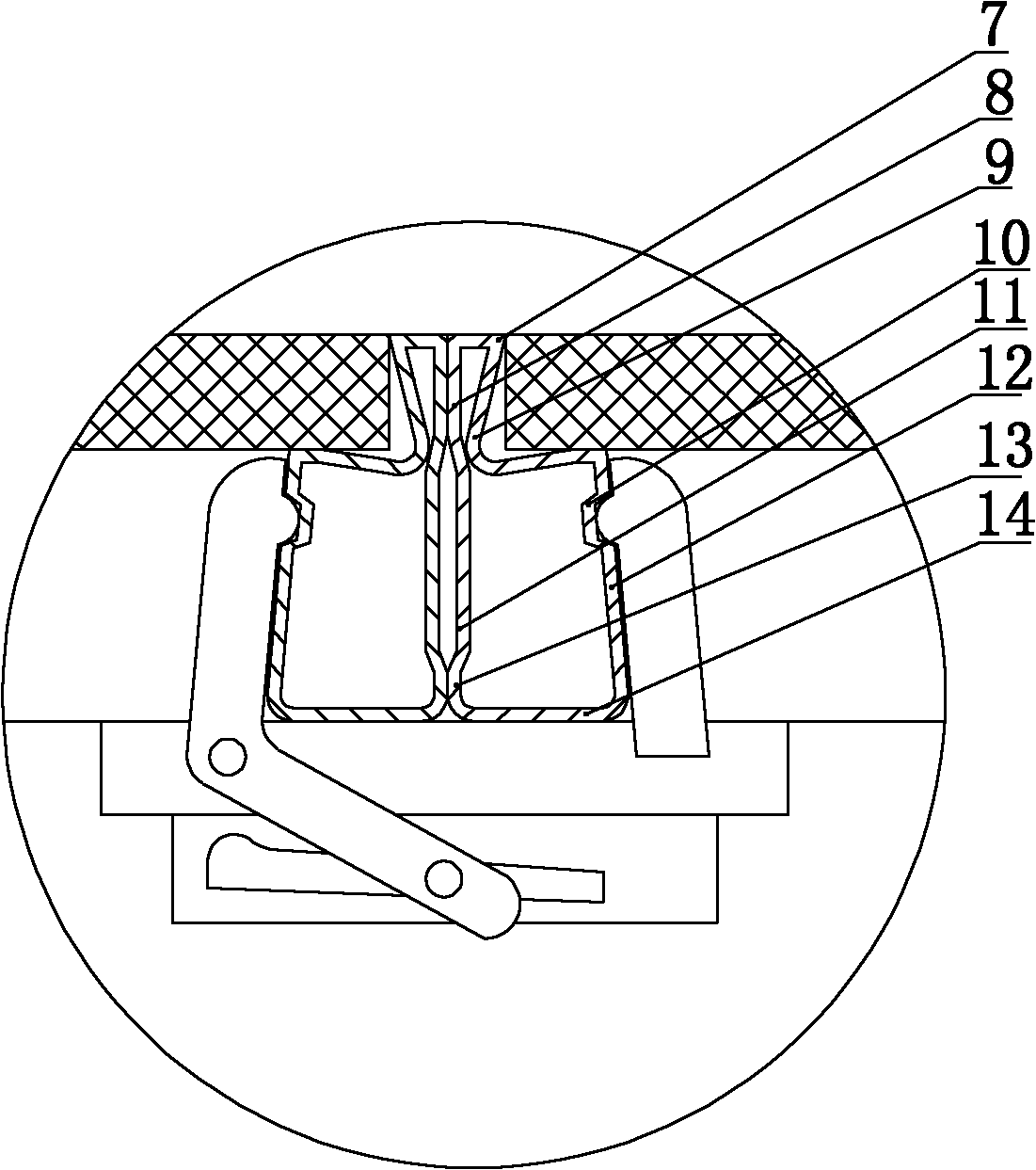

[0041] The steel frame is integrally made of the inner end 7 of the embedded panel and the outer end 14 used for connection and install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com