Valve high-temperature type test device

A technology of experimental devices and valves, which is applied in the testing of measuring devices, instruments, and mechanical parts, etc., can solve the problems that type test data cannot be collected automatically, and achieve the effect of high work efficiency and accurate test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

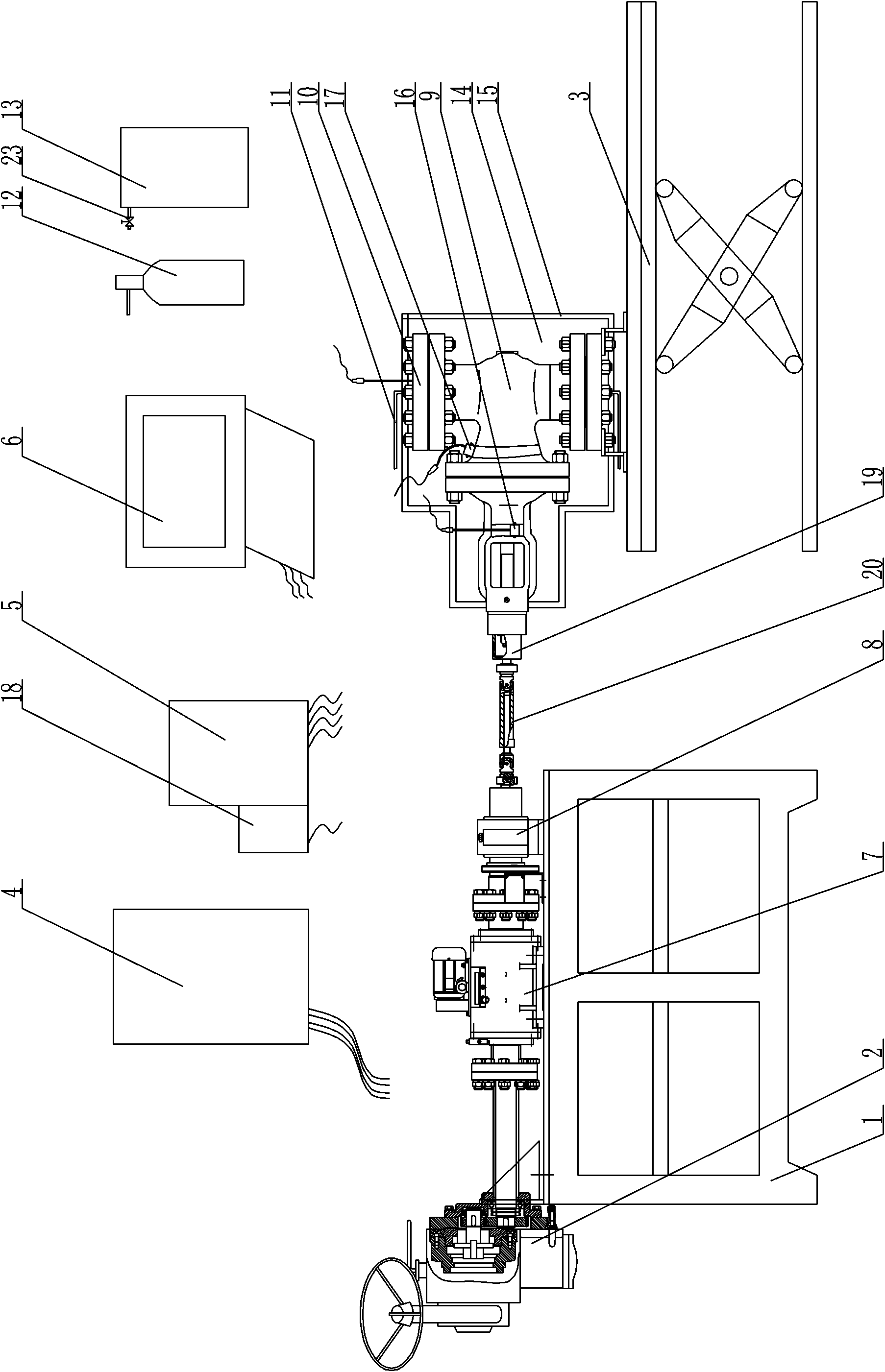

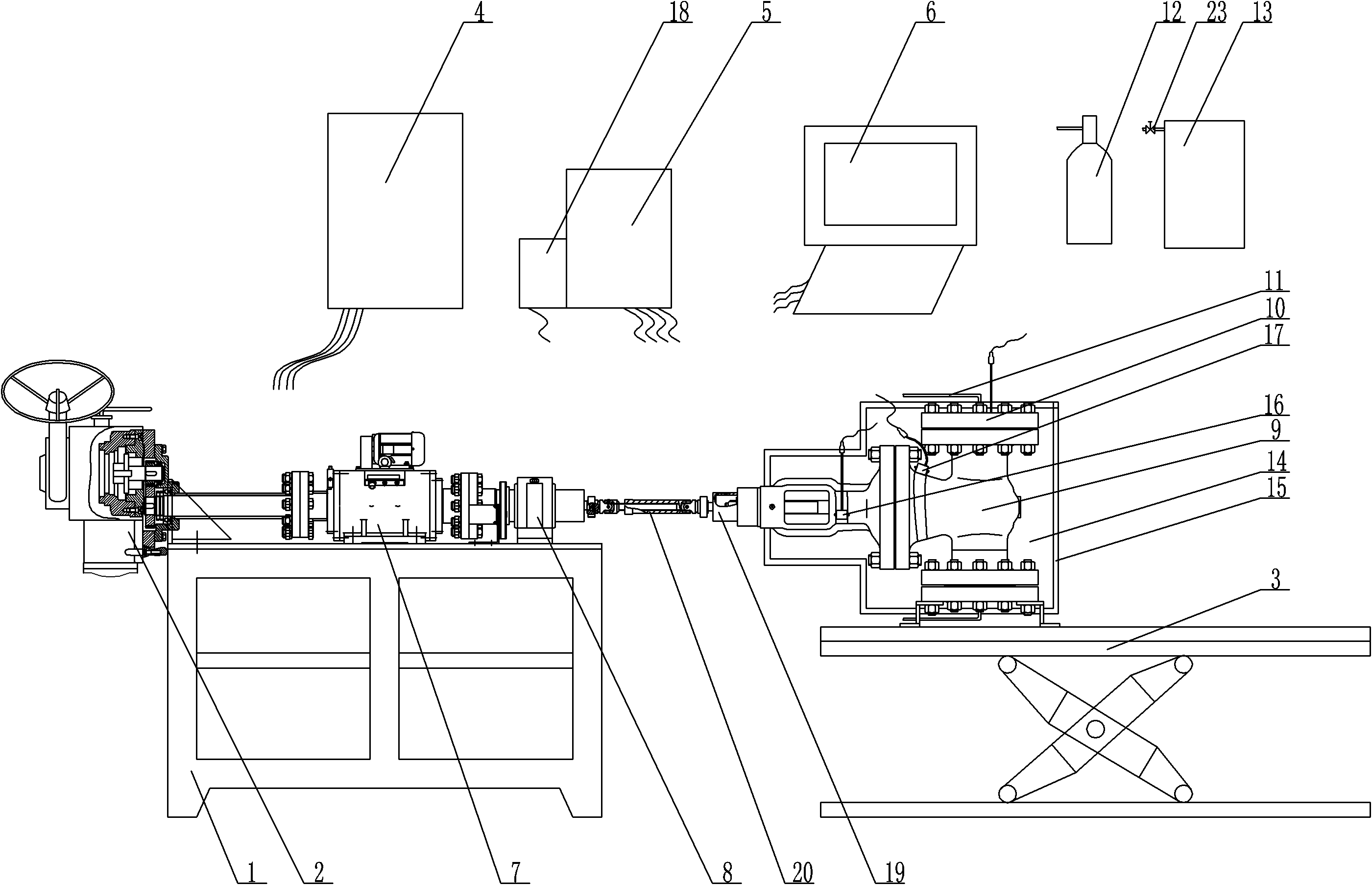

[0018] The present invention will be further described below in conjunction with accompanying drawing:

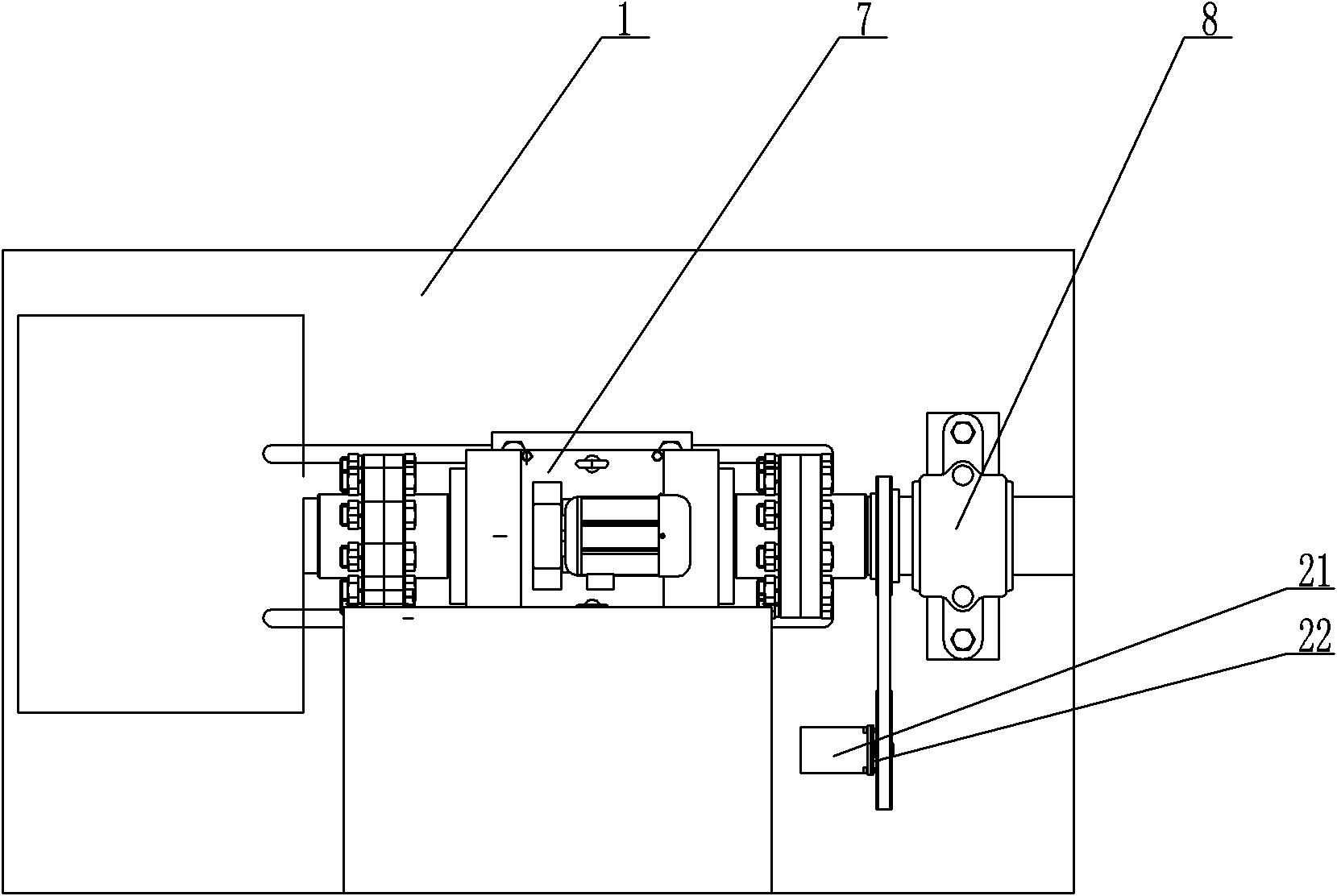

[0019] Depend on figure 1 combine figure 2 As shown, the valve high-temperature type experimental device includes a test bench 1, a power source 2, a workbench 3, an electrical cabinet 4, a display instrument 5 and a computer system 6, and the test bench 1 is equipped with a power source 2 and a torque sensor 7 And support base 8, the input end of described torque sensor 7 is connected with the output shaft of power source 2, and the output end of described torque sensor 7 passes through support base 8 and is connected with the valve stem on the valve 9 to be tested, and on the valve stem When the position changes, the reaction force generated will be applied to the support seat 8, which can avoid damage to the torque sensor 7; the valve 9 to be tested is placed on the workbench 3, and the inlet and outlet of the valve 9 to be tested are fixed with end face seals Plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com