Laser-electromagnetic ultrasound method and probe device for non-destructive testing of thermal barrier coating

A non-destructive testing and thermal barrier coating technology, which can be used in measuring devices, analyzing solids using sonic/ultrasonic/infrasonic waves, and using sonic/ultrasonic/infrasonic waves for material analysis, which can solve problems such as the lack of perfect non-destructive testing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

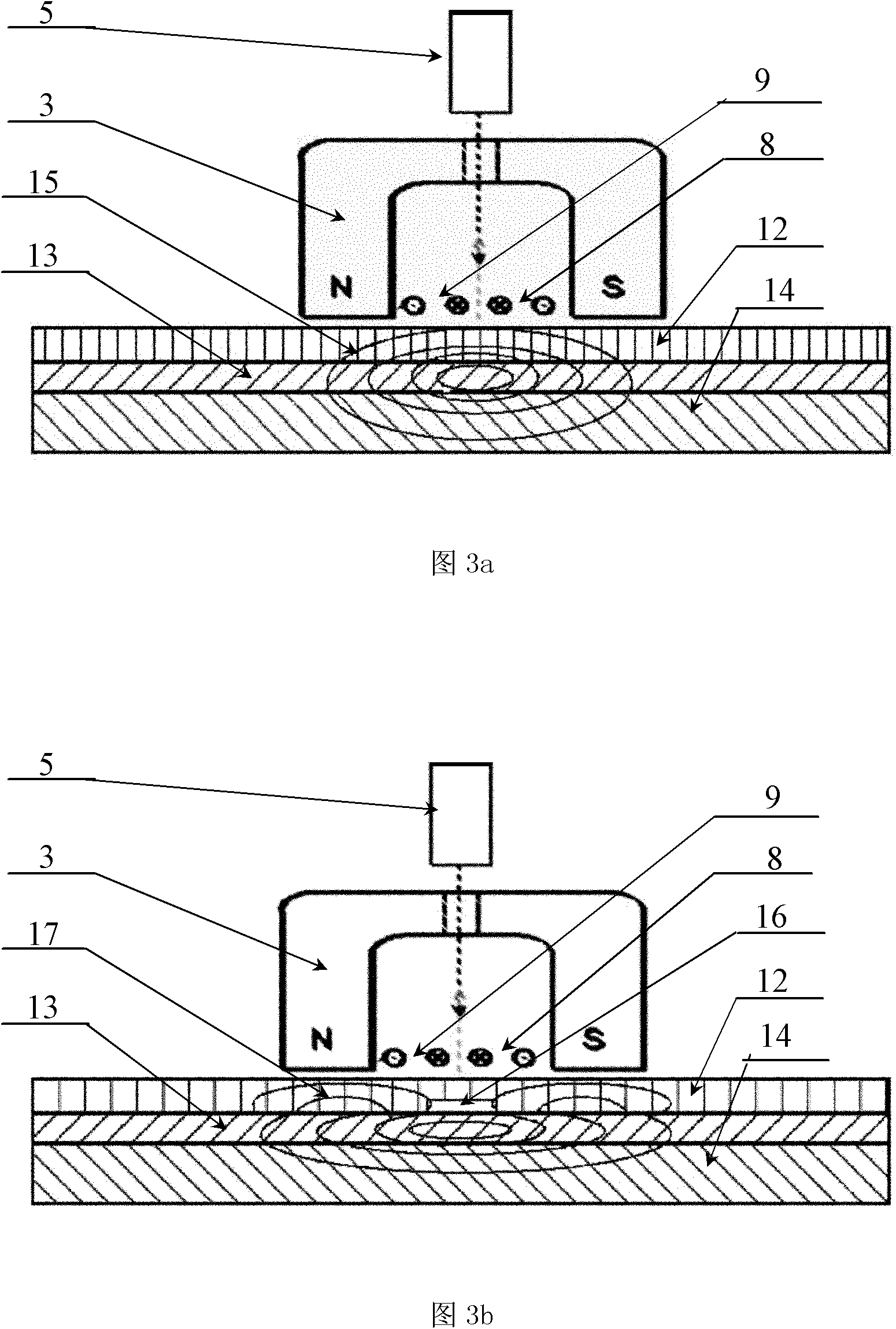

[0022] The working principle and process of the present invention will be further described in detail below in conjunction with the accompanying drawings.

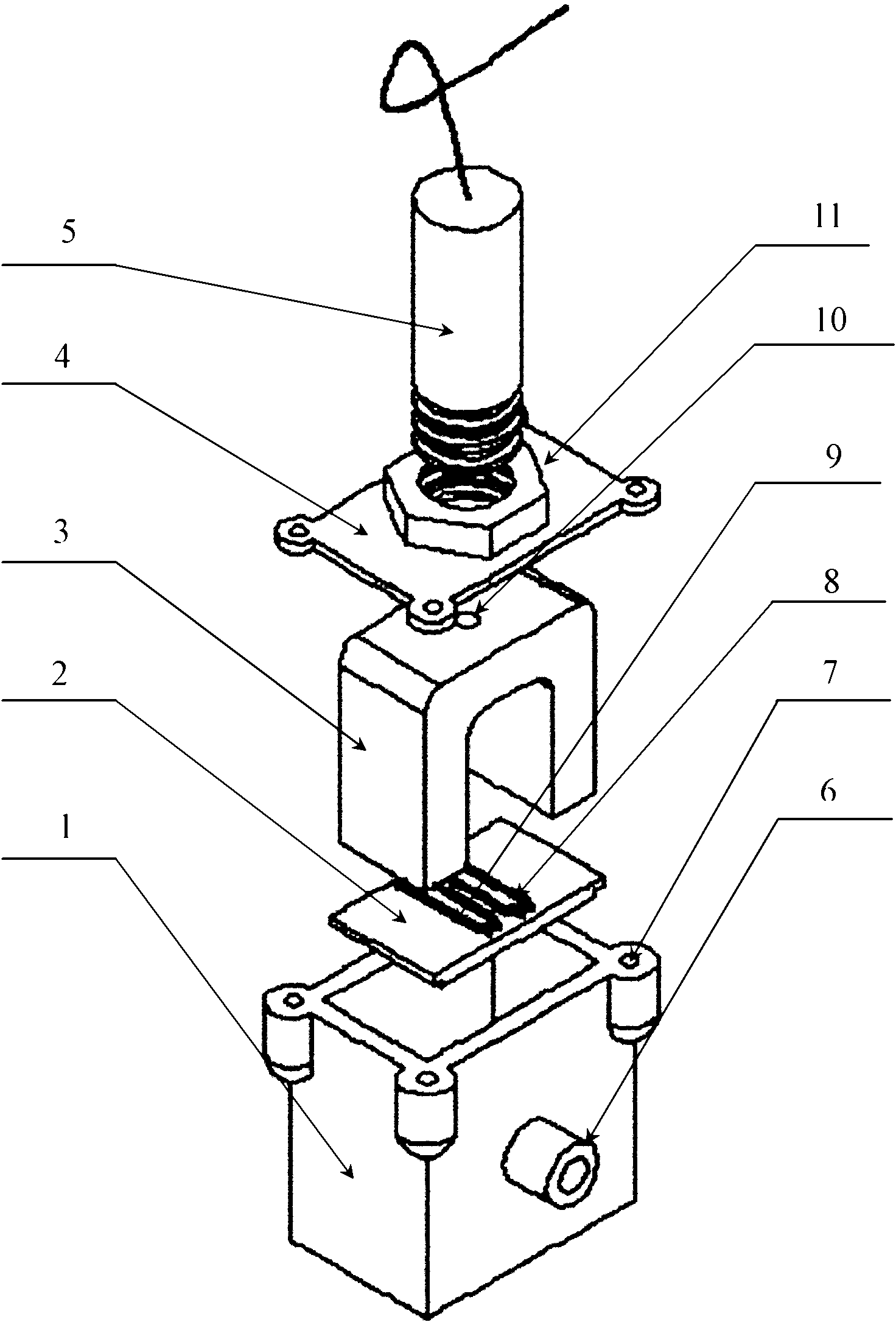

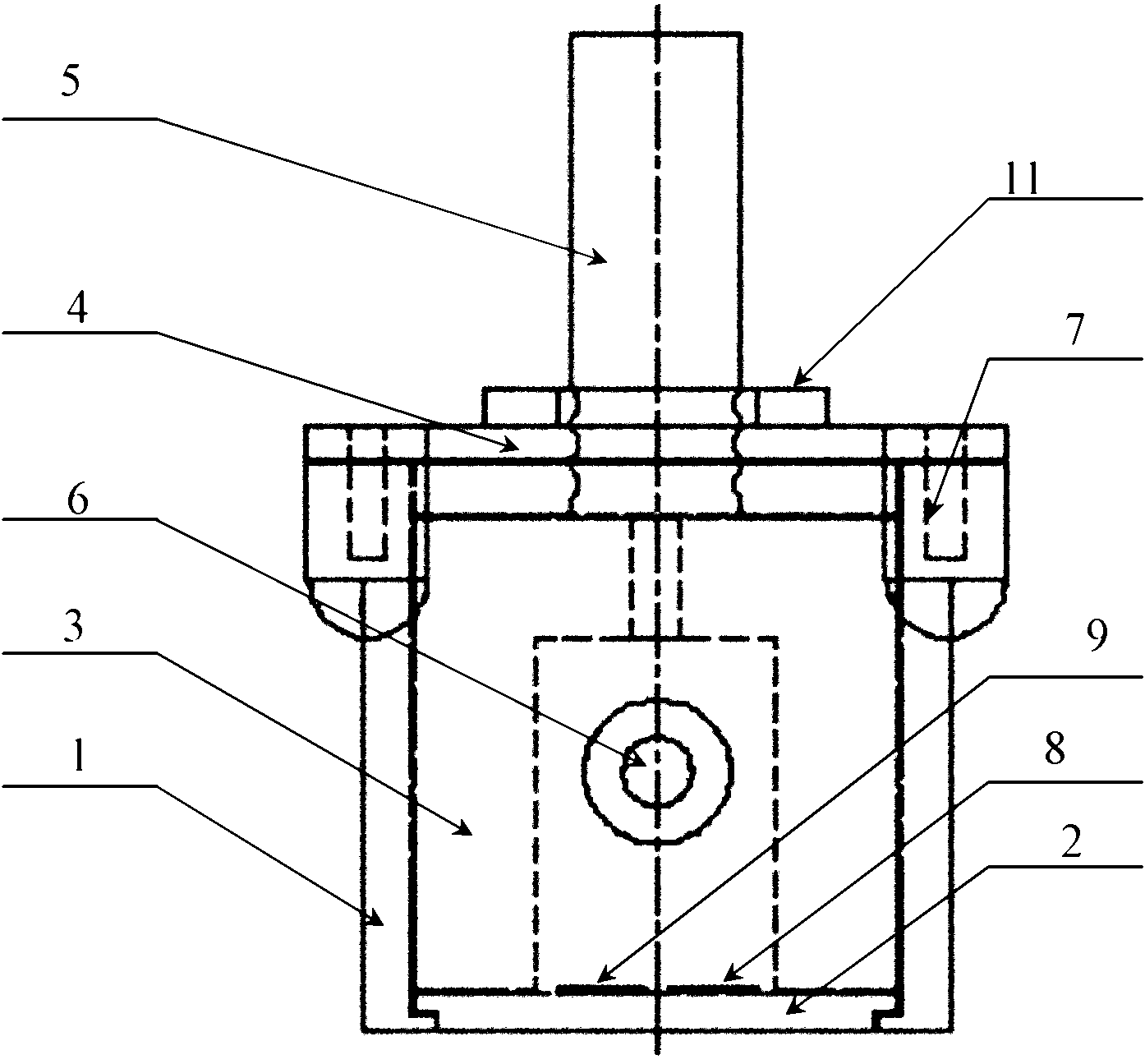

[0023] refer to figure 1 The main components of the detection probe used in the present invention include a square barrel-shaped housing 1 with both ends of the interior with bosses, a bottom plate 2 made of insulating material, a U-shaped permanent magnet 3 for providing a static magnetic field, and a lower bottom surface A cover plate 4 with a boss, a laser interferometer head (laser receiver) 5 for receiving ultrasonic signals, a signal input port 6 located on the open square barrel-shaped shell 1, and the outer edge of the upper end of the square barrel-shaped shell 1 is uniform There are 4 installation holes 7 for connecting the cover plate 4, and 2 rectangular excitation coils 8 and 9 for generating eddy currents. When in use, a reverse pulse current is applied to the rectangular coils 8 and 9. On the U-shaped perman...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com