Method for extracting state discrimination characteristic parameter of metal drawing piece

A characteristic parameter and state discrimination technology, which is applied in the processing of detection response signals and material analysis using acoustic wave emission technology, can solve the problems of lack of peak value, lack of accuracy, and difficulty in realizing on-site real-time online detection, etc., to improve accuracy , the effect of reducing the number of samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

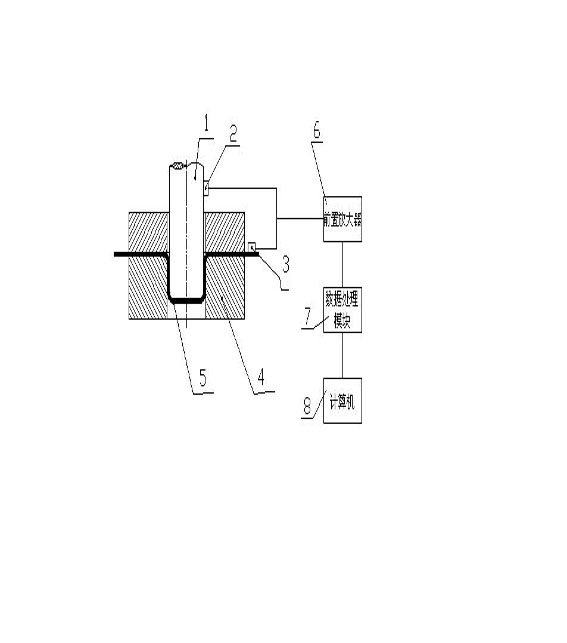

[0015] Such as figure 1 , the metal part 5 is located between the punch 1 and the die 4 during processing, because the main function of the punch 1 is to control the flow of the metal material during the deep drawing process of the metal part 5, and the function of the die 4 is to fix Metal parts 5; so in order to collect all the acoustic emission signals as far as possible, the first resonant acoustic emission sensor 2 is arranged at the edge of the punch 1, and the second resonant acoustic emission sensor 3 is arranged at the edge of the metal part 5 , the first resonant acoustic emission sensor 2 and the second resonant acoustic emission sensor 3 are respectively connected to a preamplifier 6 , and the preamplifier 6 is connected to a computer 8 through a data processing module 7 . The acoustic emission signal generated by the plastic deformation of the metal part 5 during the deep drawing process, the acoustic emission signal generated by the friction between the metal par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com