Preparation method of dye-sensitized solar cell provided with light reflecting layer

A technology of solar cells and light reflection layers, applied in the field of dye-sensitized solar cells, can solve problems such as light energy loss, achieve the effects of low cost, improve light energy utilization rate, and suppress light energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (a) Cleaning: Clean the conductive glass; use deionized water, absolute ethanol, and acetone to clean in an ultrasonic cleaner for 10 minutes, and dry in an oven; prepare 40mM TiCl 4 Solution, soak conductive glass (FTO), and dry at 70°C for 30 minutes;

[0028] Sinter the treated FTO, use an atmosphere furnace to keep warm at 325°C for 5-10 minutes, then raise the temperature to 375°C for 5-10 minutes, then raise the temperature to 450°C and keep it for 10-15 minutes, and finally raise the temperature to 500°C And keep warm for 10-15 minutes;

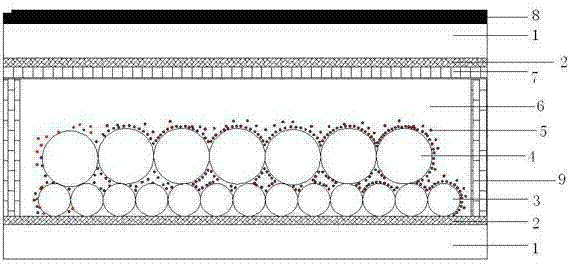

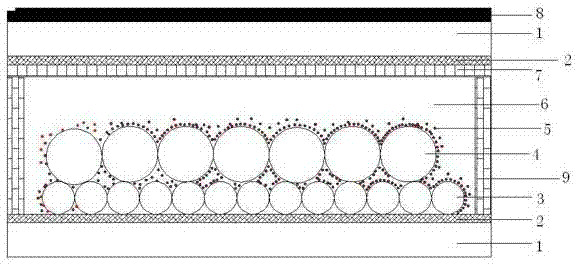

[0029] (b) Preparation of TiO 2 Nano-transparent layer: the prepared 25nm TiO 2 The slurry is coated on the surface of FTO to form TiO 2 The nano-transparent layer 3 is controlled to have a thickness of 14-16 μm through homogenization and drying processes;

[0030] (c) Preparation of TiO 2 Light scattering layer: on TiO 2 A layer of 400nmTiO is silk-screened on top of the nano-transparent layer 2 light scattering layer 4;...

Embodiment 2

[0037] This embodiment is completely the same as Embodiment 1 in steps a to d, the difference is that:

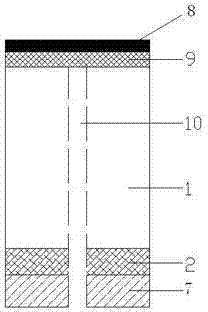

[0038] (e) Adhesive total reflection mirror, electrode butt joint packaging: the total reflection mirror is bonded to the surface of the counter electrode as a light reflection layer in an oven at 120 ° C; the counter electrode bonded with the total reflection mirror is docked with the photoanode , using sarin film for encapsulation;

[0039] (f): Injection electrolyte: In vacuum environment, inject electrolyte 6, electrolyte 6 is I -1 / I 3 -1 redox pair;

[0040] (g) Sealing of the electrolyte injection port: The electrolyte injection port 10 was sealed with a sarin film to manufacture a solar cell.

[0041] The dye-sensitized solar cells prepared in the two examples can completely reflect the light passing through the counter electrode of the cell, effectively suppress the loss of light energy, improve the utilization rate of light energy, and further increase the lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com