Patterning method for carbon-based substrate

A patterned, carbon substrate technology, applied in the input/output process of data processing, nanotechnology for materials and surface science, instruments, etc., can solve the time-consuming, complex patterning process of carbon-containing substrates, and cannot be widely used Various electronic products and other problems to achieve the effect of increasing the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] An embodiment is proposed below for detailed description, and the embodiment is only used as an example for illustration, and does not limit the scope of protection of the present invention. In addition, the drawings in the embodiments omit unnecessary components to clearly show the technical characteristics of the present invention.

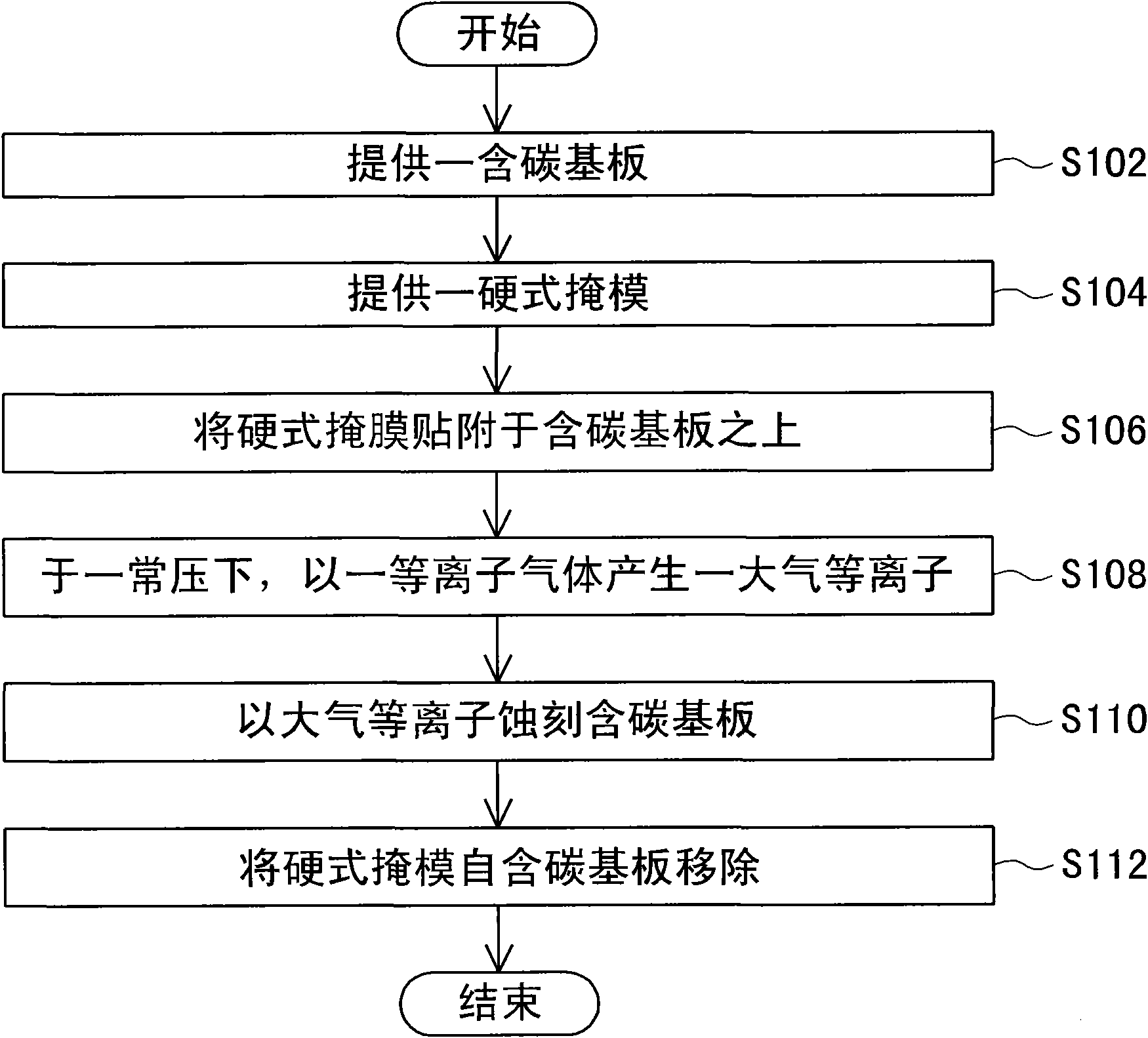

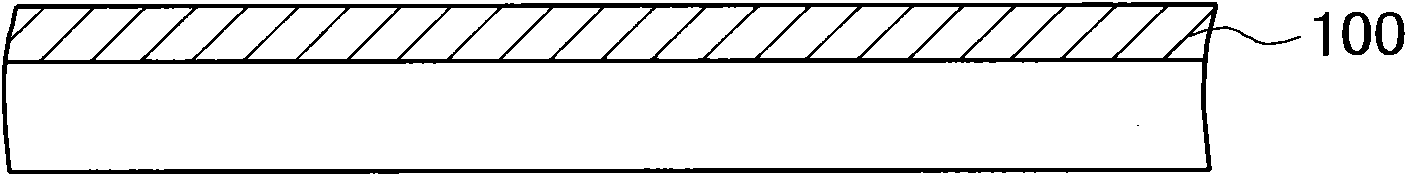

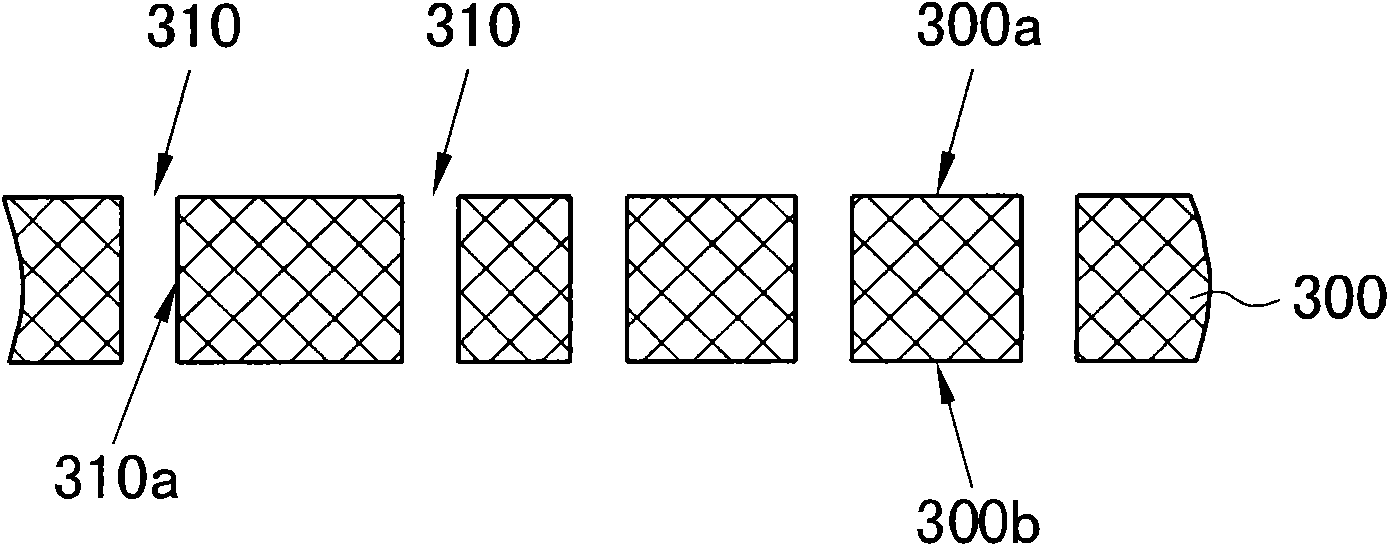

[0033] Please refer to figure 1 and Figure 2 to Figure 7 , figure 1 A flowchart illustrating a method for patterning a carbon-containing substrate 100, Figure 2 to Figure 7 draw figure 1 A schematic diagram of the steps.

[0034] First, in step S102, if figure 2 As shown, a carbon-containing substrate 100 is provided. In this embodiment, the carbon-containing substrate 100 is illustrated by taking a transparent carbon nanotube-based thin film (Transparent Carbon Nanotube-based Thin Film) as an example. The optical properties of the carbon nanotube transparent conductive film are similar to those of the indium tin oxide film (Ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com