High-safety lithium ion battery

A lithium-ion battery, safety performance technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] According to the lithium ion secondary battery provided by the present invention, the main steps of the preparation method of the battery are well known to those skilled in the art. Generally speaking, the preparation method of the battery includes placing the electrode group in the battery case, adding an electrolyte, Then it is sealed to obtain a lithium ion secondary battery. Wherein, the sealing method and the usage amount of the electrolyte are known to those skilled in the art.

[0024] As long as it is noted that when adding a conductive agent to the positive electrode slurry and / or negative electrode slurry, it should be noted that the conductive agent should use a high-molecular positive temperature coefficient heat-sensitive material.

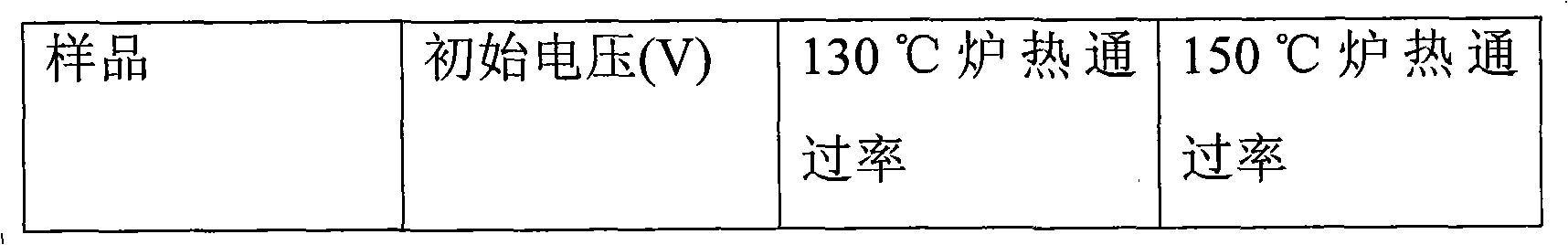

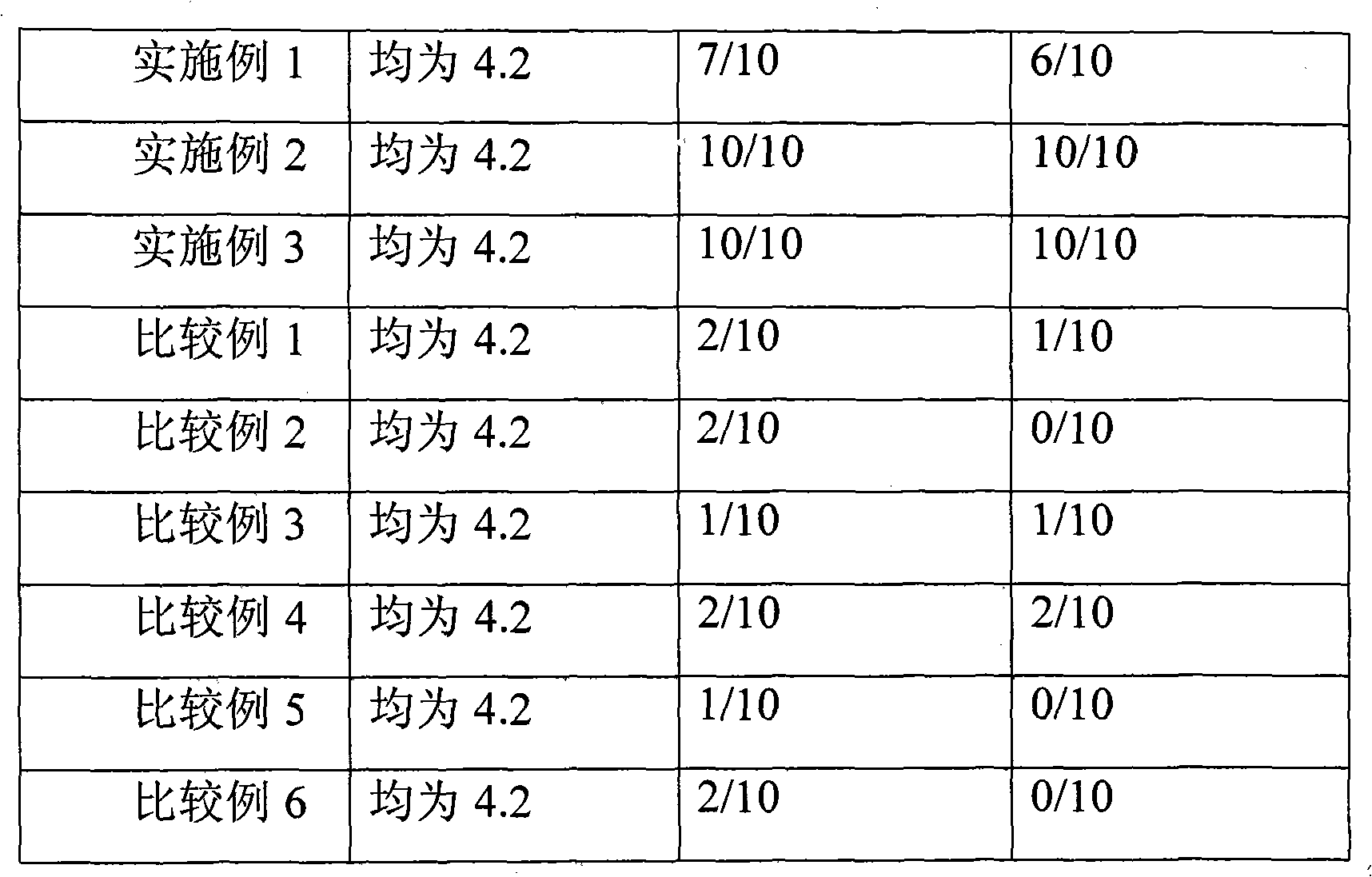

Embodiment 1

[0026] The positive active material is LiCoO2, and the binder is PVDF. Dissolve PVDF in the solvent NMP to prepare a PVDF solution, put the positive electrode active material and the conductive polymer substance as a conductive agent together into the solvent, and mix well to make a positive electrode slurry, which is composed of LiCoO2:PVDF:polymer Conductive agent = 100:8:6.89. Coating and sheeting the prepared positive electrode slurry.

[0027] Graphite is used as the negative electrode active material, and CMC and SBR are used as the binder. Dissolve CMC in water to make CMC solution, add graphite into the solvent, mix well, then add SBR emulsion to make slurry, which consists of graphite: CMC: SBR: polymer conductive agent = 100: 1.5: 2.5: 3.22. The prepared negative electrode slurry is coated and made into sheets.

[0028] The above-mentioned positive electrode sheet, negative electrode sheet, and separator are wound to form the pole core of the lithium-ion square b...

Embodiment 2

[0030] The positive electrode slurry composition in Example 1 was changed to LiCoO2:PVDF:polymer conductive agent=100:8:4.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com