Switched reluctance motor of directly-driven submersible screw pump

A technology of switched reluctance motors and electric shafts, which is applied in the direction of electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve the problems of large power consumption, high loss, and insufficient motor utilization, and achieve reduced system costs and performance Reliable, Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

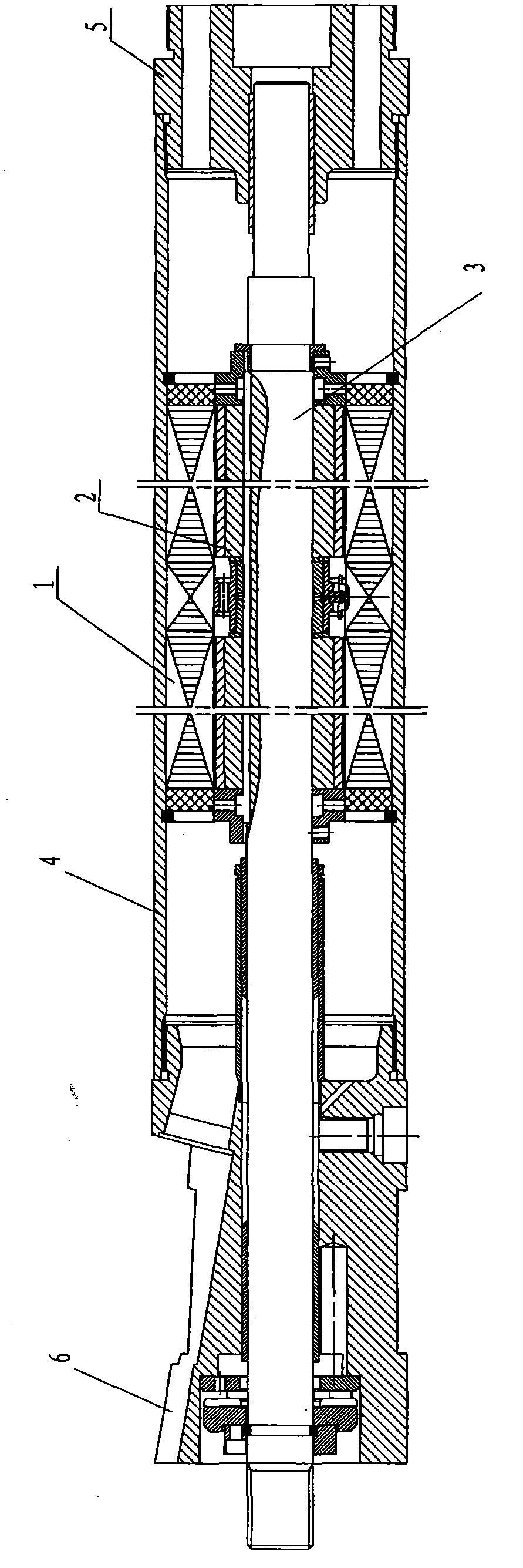

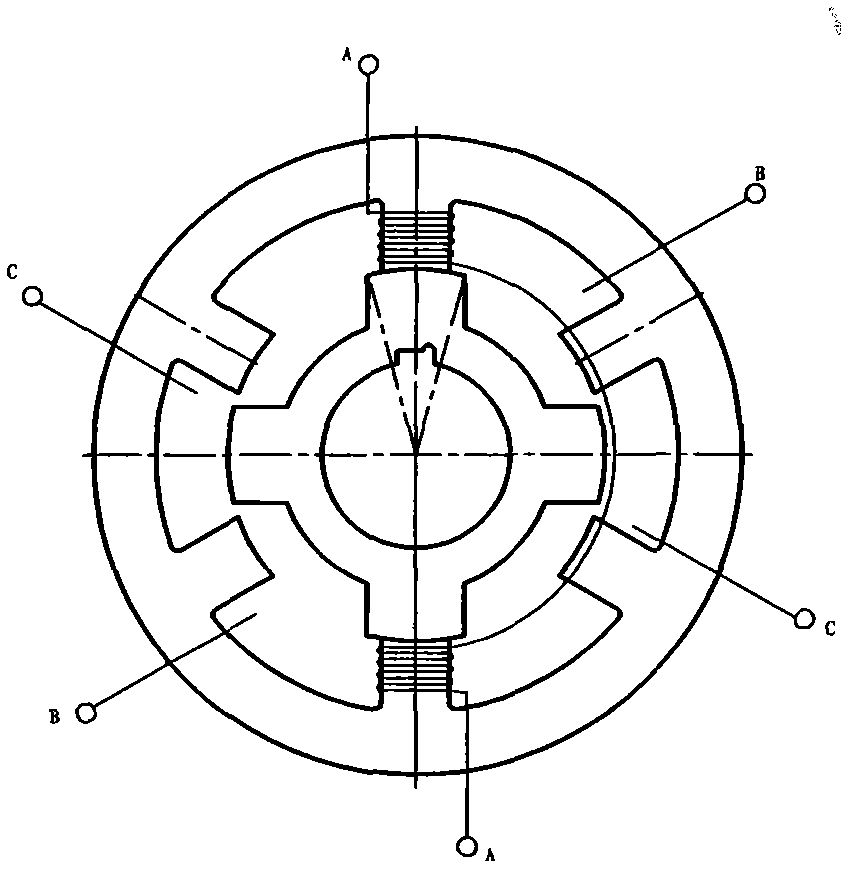

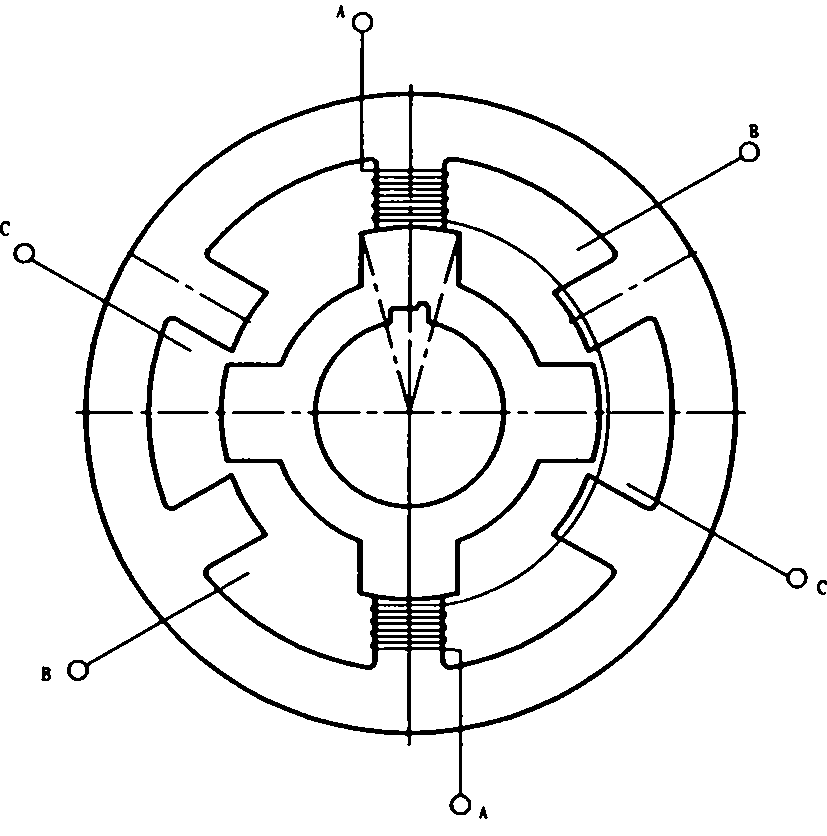

[0017] Such as figure 1 As shown in , the switched reluctance motor includes a motor casing 4, an upper joint 6 and a lower joint 5 arranged at both ends of the motor casing, and a stator 1, a rotor 2 and an electric shaft 3 arranged in the motor casing. The rotor 2 is composed of several subsections, and the subsections are a power generation structure composed of a stator and a rotor. The motor in the present invention is composed of 8 subsections, that is, 8 subsections connected in series. Such as figure 2 As shown, the rotor 2 is fixed on the electric shaft 3, and the stator 1 is arranged outside the rotor 2. The motor adopts a three-phase 6 / 4 structure, that is, the stator 1 is provided with three sets of symmetrically arranged stator teeth 1a, A, B, and C, and each stator tooth 1a is provided with a concentrated winding coil 1b, and two radially opposite coils They are connected in series to form a phase winding, and two sets of four rotor teeth 2a are arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com