Multi-layer HDI circuit board blind hole windowing process

A window-opening process and circuit board technology, which is applied in printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of unstable quality and insufficient laser blind hole window opening accuracy, so as to reduce the manufacturing difficulty and ensure blind hole opening. Window quality and blind hole quality, the effect of optimizing the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

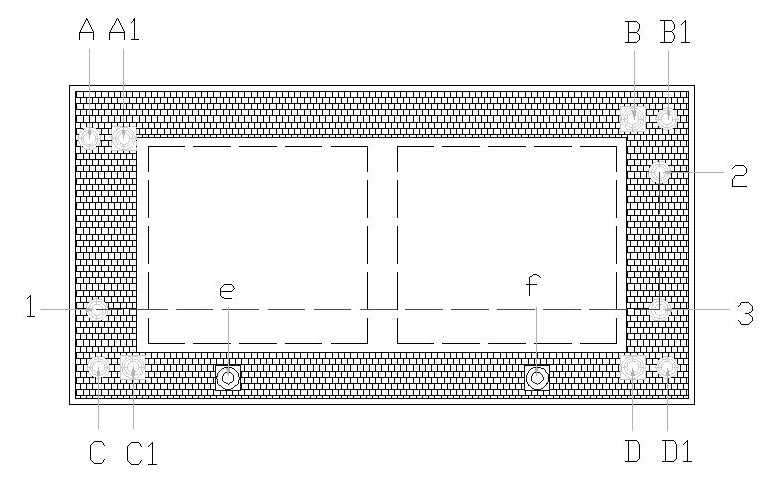

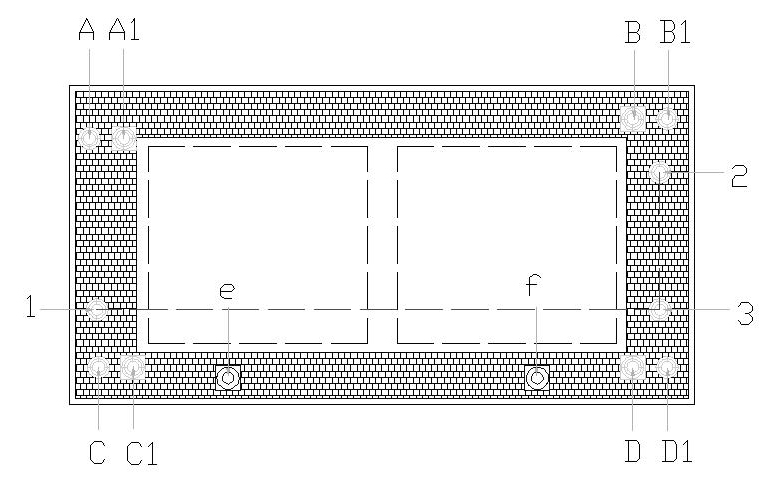

[0016] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings:

[0017] The laser blind hole window opening process steps of the multi-layer HDI circuit board disclosed by the present invention are as follows:

[0018] (1) Make the target hole pattern on the PAD layer at the bottom of the laser blind hole;

[0019] (2) Use LD PP or RCC resin copper foil for lamination;

[0020] (3) Use X-RAY machine to drill target holes;

[0021] (4) Use automatic exposure machine for alignment and exposure;

[0022] (5) Development;

[0023] (6) Blind hole etching window opening.

[0024] In this process, four key technologies need to be overcome, namely: sub-outer layer target hole pattern making, X-RAY machine targeting hole, automatic exposure machine alignment and exposure, blind hole etching and window opening.

[0025] In process step 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com