Hexaflumuron suspended emulsion

A technology of urea suspoemulsion and hexaflumuron, applied in the field of pesticides, can solve problems such as large negative impact on the environment, combustion, explosion, poisoning, etc., and achieve the effects of environmental protection, good stability and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

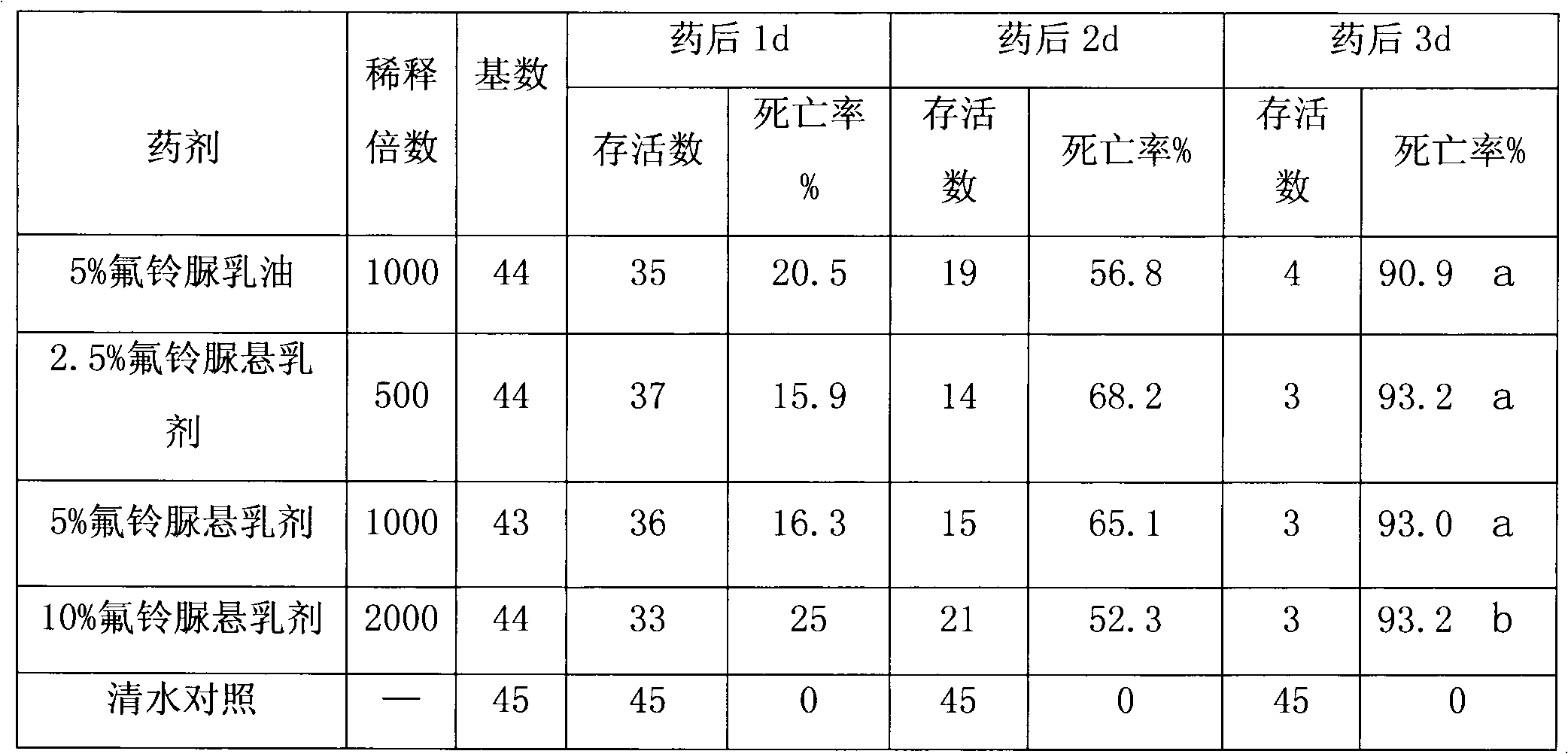

Examples

Embodiment 1

[0021] The formula of 2.5% hexaflumuron suspoemulsion is as follows:

[0022] Hexaflumuron 2.5g

[0023] Polyoxyethylene ether phosphate 18.0g

[0024] Silica 2g

[0025] Ethylene glycol 2g

[0026] Phenylphenol polyoxyethylene ether 8.0g,

[0027] Xylene 7.5g,

[0028] Water 60.0g.

[0029] Above-mentioned formula is prepared according to the following steps:

[0030] (1) Preparation of suspending agent

[0031] Mix and grind hexaflumuron technical, polyoxyethylene ether phosphate, white carbon black and appropriate amount of water to prepare hexaflumuron suspension;

[0032] (2) Preparation of water-emulsion phase

[0033] Mix ethylene glycol, phenylethylphenol polyoxyethylene ether, and xylene, and after mixing, add an appropriate amount of water to form a uniform water-emulsion phase;

[0034] (3) mixed shear

[0035] Add the prepared suspending agent into the shearing kettle, add the prepared aqueous emulsion phase into the suspending agent, shear at high speed,...

Embodiment 2

[0037] The formula of 5% hexaflumuron suspoemulsion is as follows:

[0038] Hexaflumuron 5.0g

[0039] Polyoxyethylene ether phosphate 21.0g

[0040] Silica 4g

[0041] Propylene glycol 2g

[0042] Phenylphenol polyoxyethylene polyoxypropylene ether 10.0g

[0043] Xylene 10.0g

[0044] Water 48.0g

[0045] Above-mentioned formula is prepared according to the following steps:

[0046] (1) Preparation of suspending agent

[0047] Mix and grind hexaflumuron technical, polyoxyethylene ether phosphate, white carbon black and appropriate amount of water to prepare hexaflumuron suspension;

[0048] (2) Preparation of water-emulsion phase

[0049] Mix propylene glycol, phenylethylphenol polyoxyethylene polyoxypropylene ether, and xylene, and after mixing, add an appropriate amount of water to form a uniform water-emulsion phase;

[0050] (3) mixed shear

[0051] Add the suspending agent into the shearing kettle, add the prepared water-emulsion phase into the suspending agent...

Embodiment 3

[0053] The formula of a kind of hexaflumuron suspoemulsion is as follows:

[0054] Hexaflumuron 10.0g

[0055] Polyoxyethylene ether phosphate 21.0g

[0056] Silica 5g

[0057] Glycerol 2g

[0058] Alkylphenol polyoxyethylene polyoxypropylene ether 12.0g

[0059] Xylene 10.0g

[0060] Water 40.0g

[0061] Above-mentioned formula is prepared according to the following steps:

[0062] (1) Preparation of suspending agent

[0063] Mix and grind hexaflumuron technical, polyoxyethylene ether phosphate, white carbon black and appropriate amount of water to prepare hexaflumuron suspension;

[0064] (2) Preparation of water-emulsion phase

[0065] Mix glycerol, alkylphenol polyoxyethylene polyoxypropylene ether, and xylene, and after mixing, add an appropriate amount of water to form a uniform water-emulsion phase;

[0066] (3) mixed shear

[0067] Add the suspending agent into the shearing kettle, add the above prepared water-emulsion phase into the suspending agent, shear a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com