Backwards-turnable type hand surgery quick-assembling handle

A twist-back hand and handle technology, applied in the field of medical devices, can solve the problems of high cost of surgical instruments, increase the cost of disinfection, occupy a large space, etc., save space for disinfection and transportation costs, and the process of installation or disassembly is convenient and fast. The effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

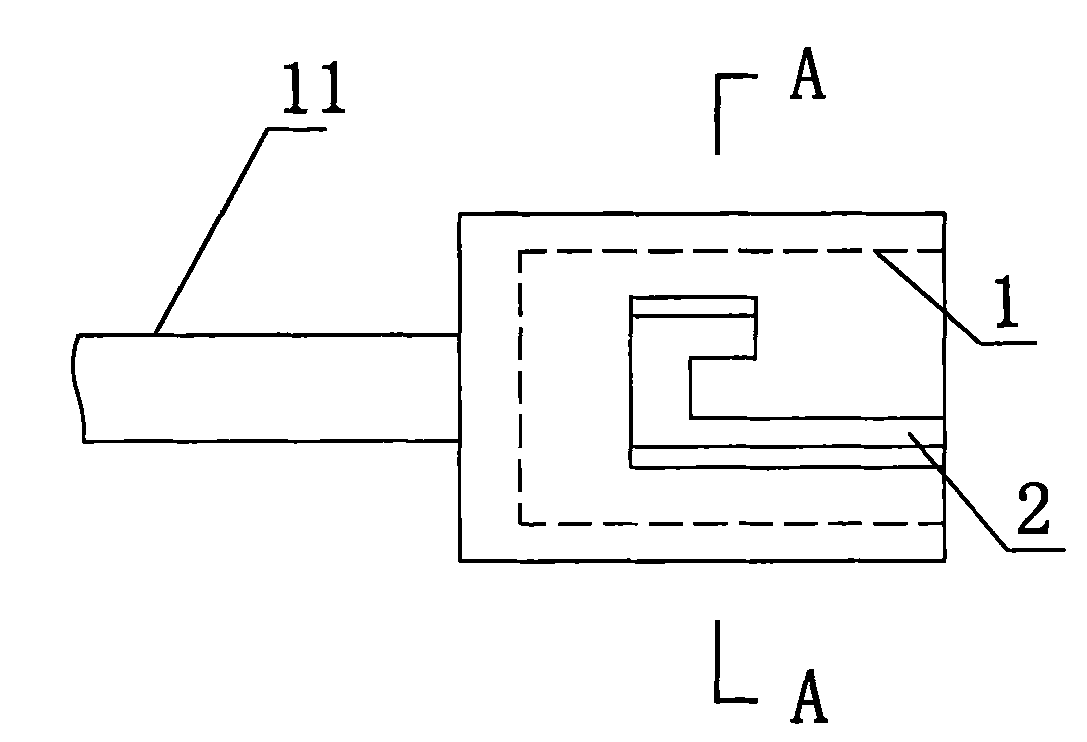

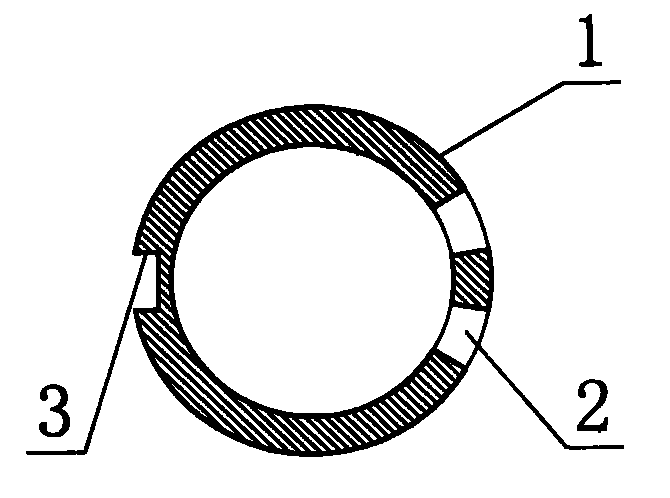

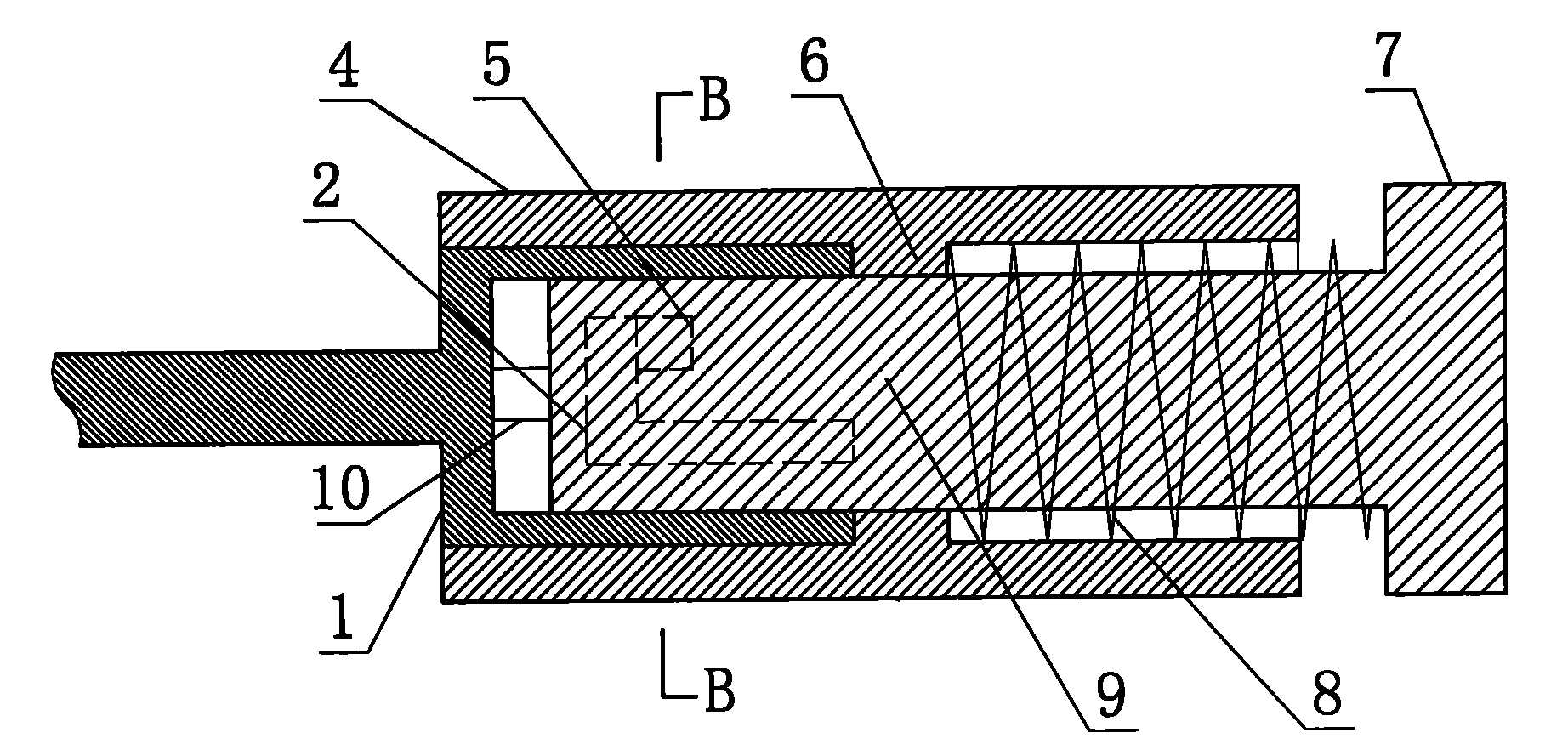

[0017] The twist-back hand surgery quick-loading handle consists of a base 1, a positioning groove 2, an anti-rotation groove 3, a sleeve 4, a positioning block 5, a snap ring 6, a tail plate 7, a spring 8, a handle 9, a convex strip 10 and a replacement head 11 composition. Wherein, the base 1 is cylindrical with the left end closed and the right end open, the left end of the base 1 is integrated with the replacement head 11, and there is a longitudinal anti-rotation groove 3 with a rectangular cross section on the side wall of the base 1 , There is also n-shaped positioning groove 2 on the side wall of the base 1, and the positioning groove 2 is made of two longitudinal straight grooves along the longitudinal direction of the base 1 and a transverse groove of unequal length. The left ends of the two longitudinal straight grooves are aligned, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com