Machining method for fixed angle plate of automobile instrument skeleton beam

A technology of automobile instrument panels and processing methods, which is applied to vehicle parts, transportation and packaging, etc., can solve problems that do not meet the needs of market competition, complex process methods, and complex beam structures, and achieve good economic benefits, simple and fast processing, and The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

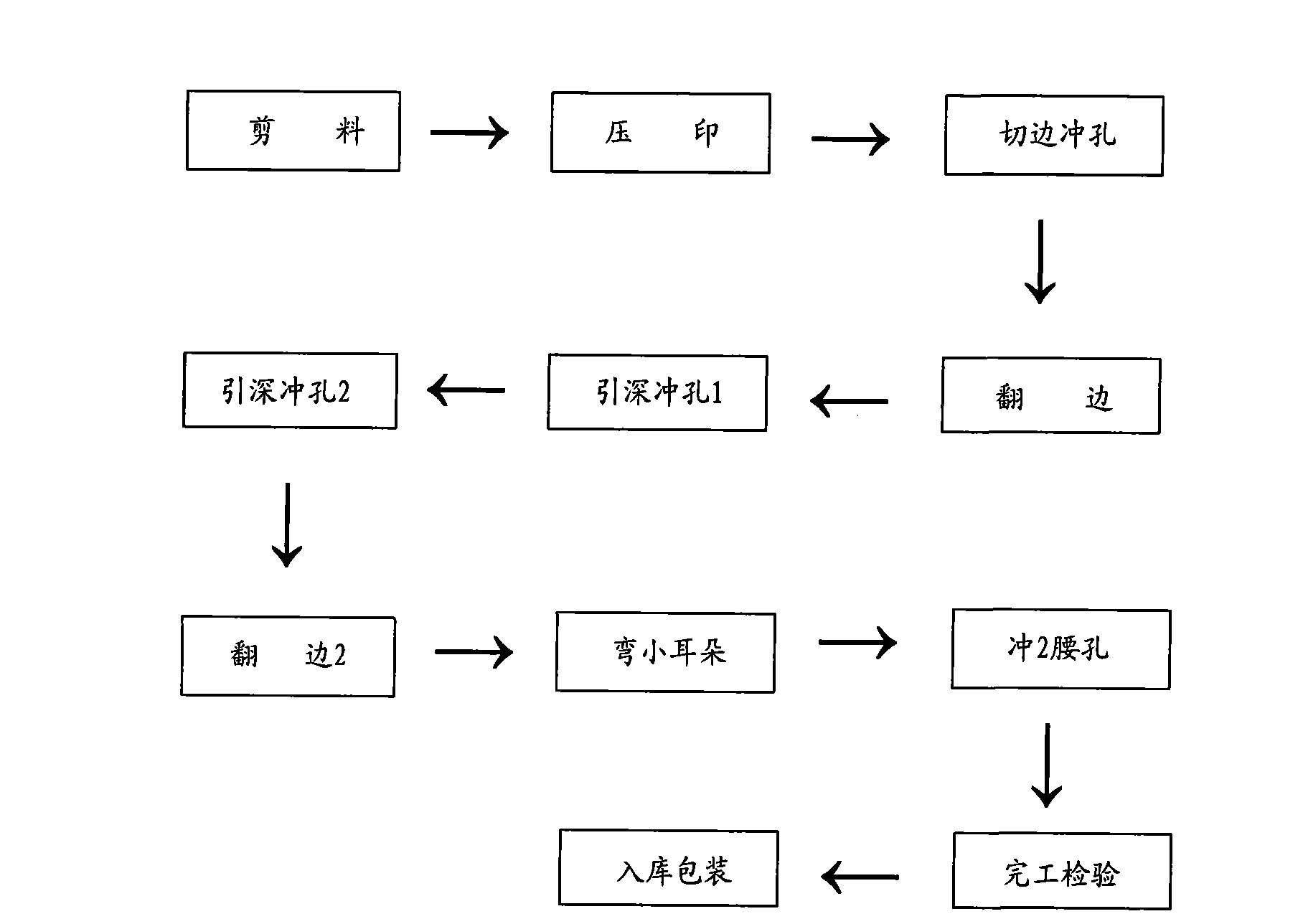

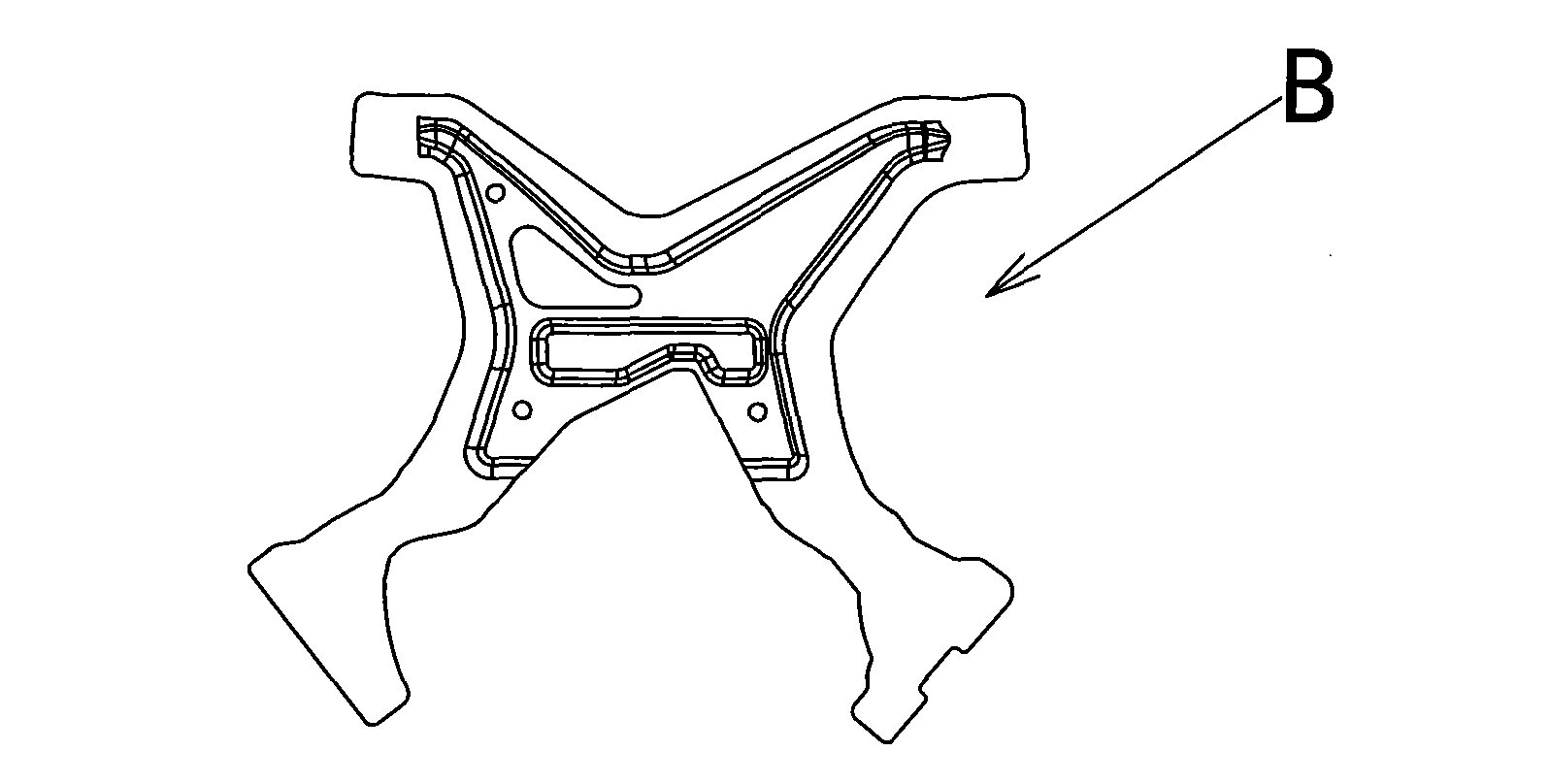

[0028] see Figure 1-8 , the method for processing the fixed angle plate of the skeleton beam of the automobile instrument panel, comprising the following steps:

[0029] Cutting material: Select a sheet material of 0.8mm*1120mm*2560mm, and use a QC2Y-6*2500 shearing machine to cut it into 32 pieces of blanks with a size of 0.8mm*320mm*280mm. When shearing, the sheet must not be tilted, the verticality is required to be ±2mm, and the sheet rests on the positioning block of the shearing machine.

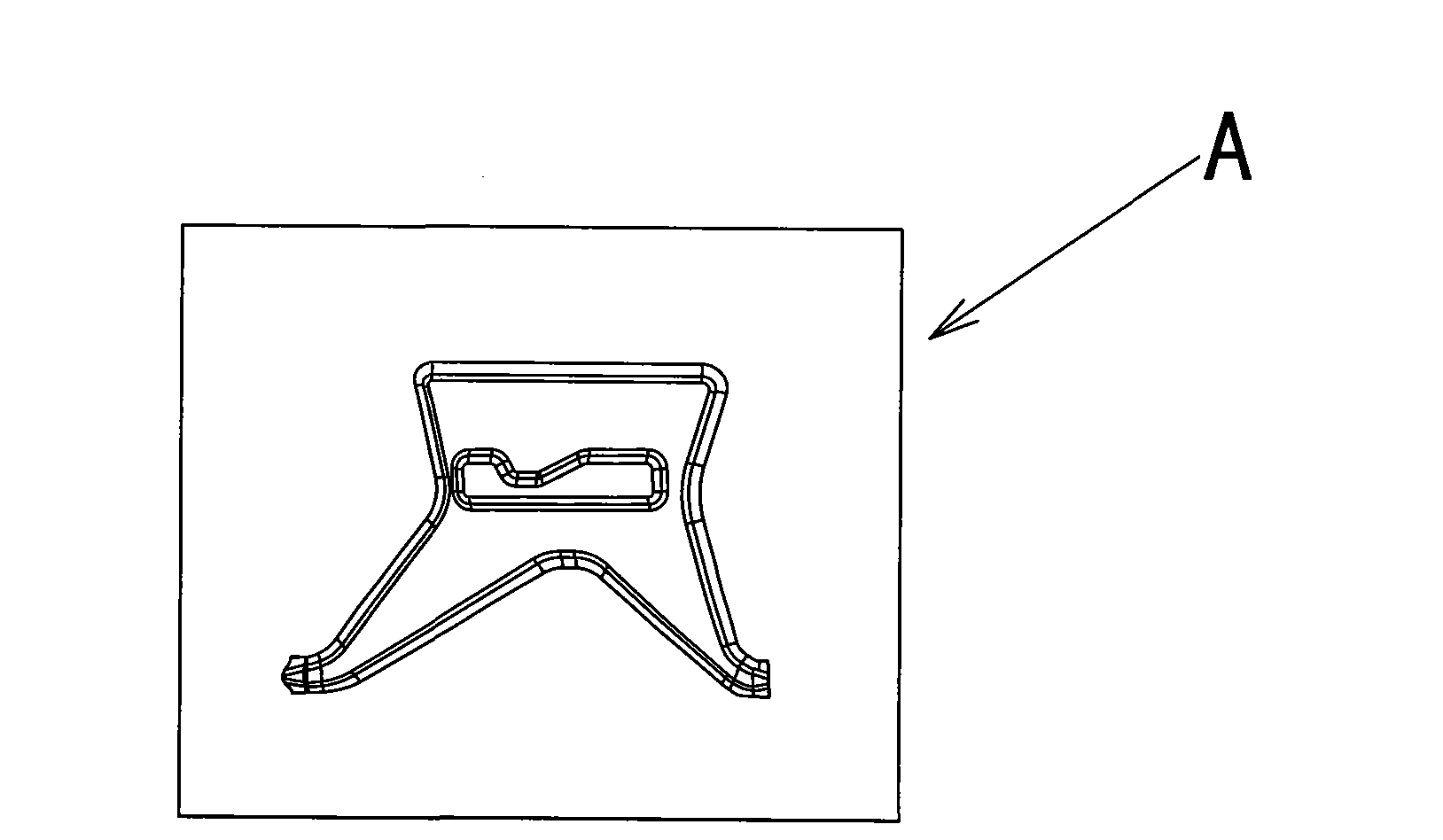

[0030] Embossing: Put the raw materials into the embossing mold (single-process mould), and add lubricating oil to the embossing mold to prevent wrinkling or cracking at the rounded corners. Through the JB23-63A punch press, the processed part A is ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com