Device for water-carrying grinding-in of grinding core and grinding cover of spherical hinge used in bridge rotation construction

A technology of grinding cover with water and construction, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems affecting the quality of bridge swivel construction, difficulty in bridge swivel, and insufficient smoothness, and achieve good lubrication. and heat dissipation, good smoothness, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

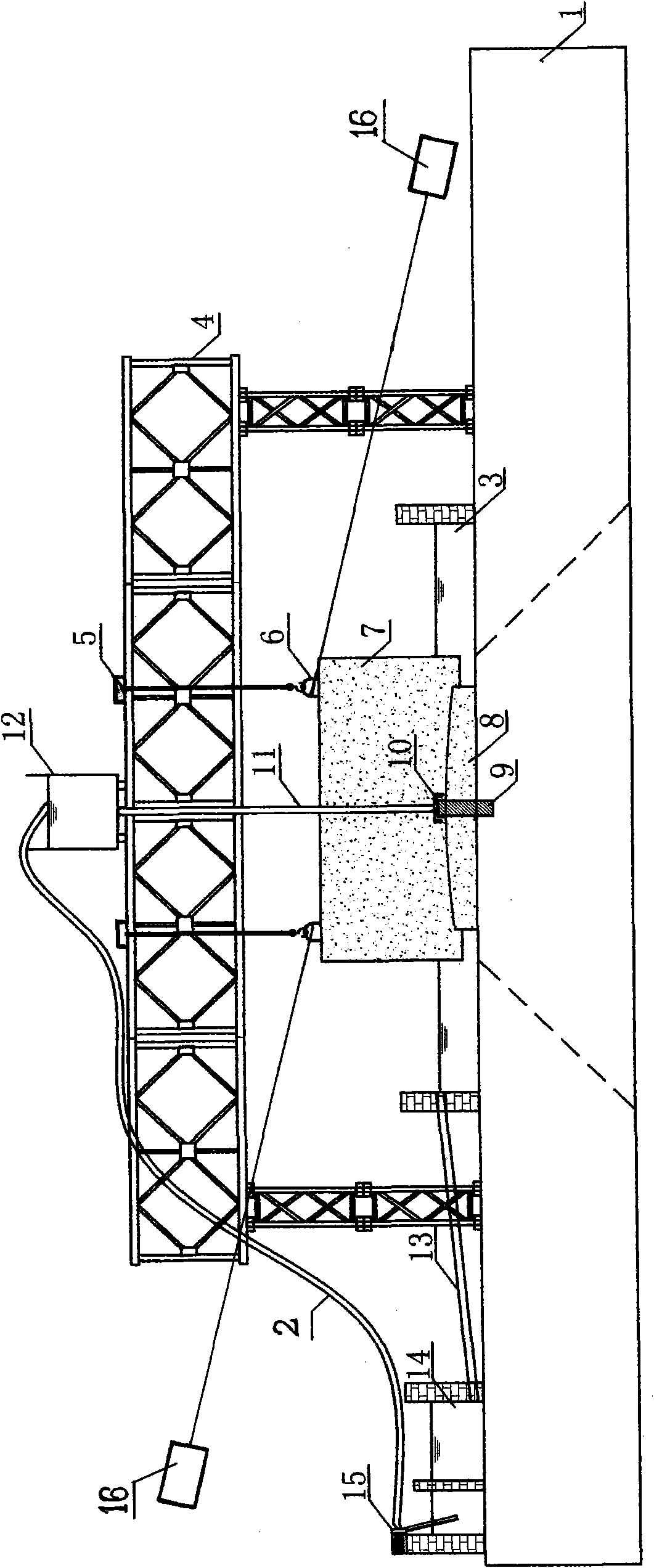

[0010] refer to figure 1 Concrete the grinding center 8 on the spherical hinge bearing platform 1, and at the same time, vertically set a grinding center positioning shaft 9 in the center of the grinding center 8; 7. Embed four grinding cover suspension rings 6 at the top and connect them with the electric hoist 5 provided on the gantry crane combination 4. A water inlet pipe 11 is vertically arranged in the center of the grinding cover 7. The upper end of the water inlet pipe 11 is connected to the The water tank 12 is connected, and the lower end is connected with an axle sleeve 10 that is located in the grinding cover 7 and is located above the grinding center positioning shaft 9 of the grinding center 8; the winch assembly 16 is symmetrically connected on both sides of the grinding cover 7; A pool 3 is set around the cover 7, and an outlet pipe 13 is arranged on one side of the pool 3; 15 communicates with a water injection pipe 2 between the water tank 12. Thus, the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com