High-temperature resistant pump

A high temperature resistant, pump body technology, applied in the direction of pumps, pump components, non-variable pumps, etc., can solve problems affecting production, device accident shutdown, etc., and achieve high efficiency, simple maintenance, and increased critical temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

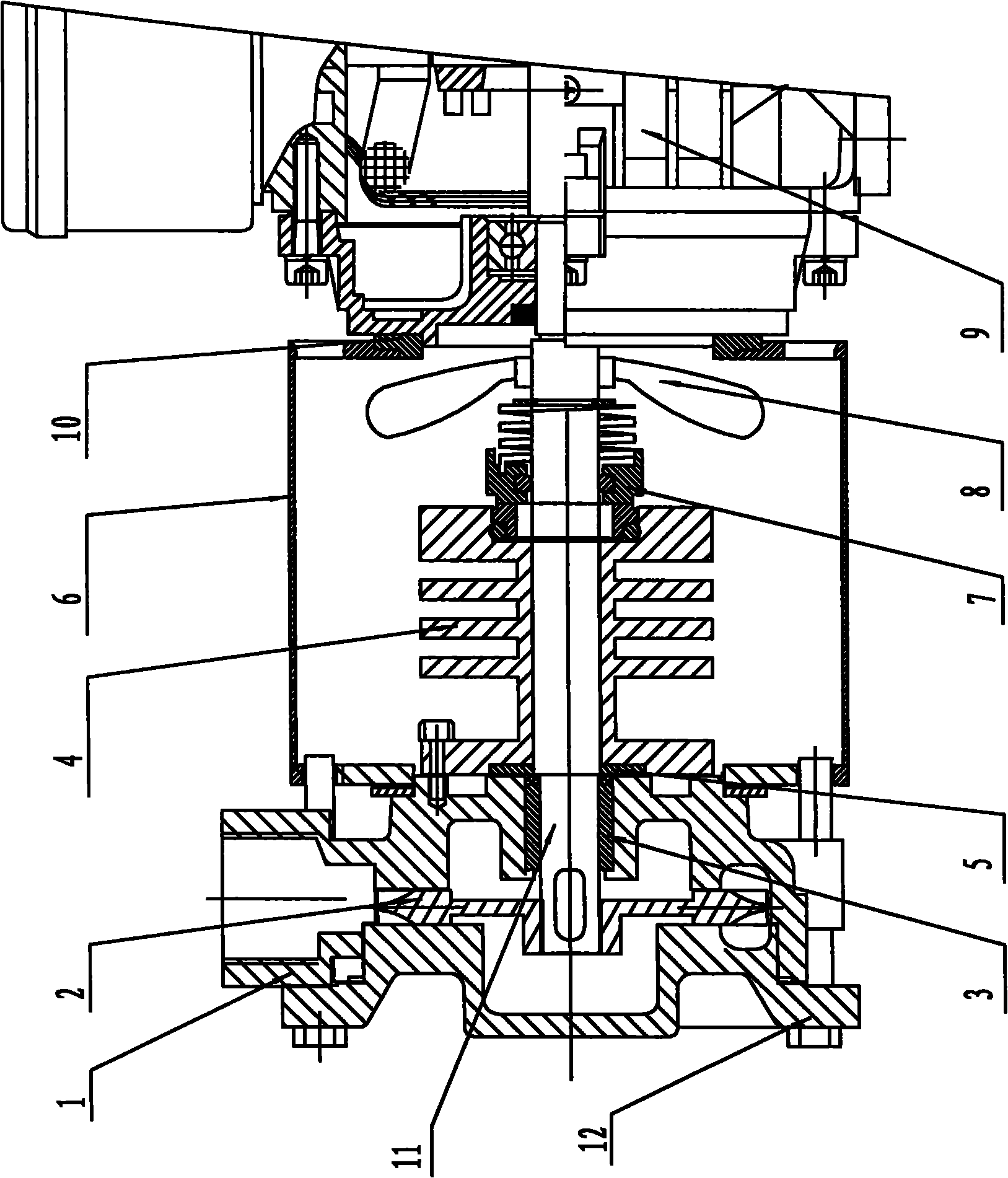

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a high-temperature resistant pump includes a pump body 1, an impeller 2, a shaft sleeve 3, a pump shaft 11, and a pump cover 12. The pump body 1 is in a "U" shape, and the pump body 1 is mounted on the shaft sleeve 3. Above, the shaft sleeve 3 is installed on the pump shaft 11; the impeller 2 is installed on the pump shaft 11 and is located in the groove of the pump body 1; the pump cover 12 is connected to the front end of the pump body 1; the pump shaft 11 and the motor 9 The main shaft is connected; it is characterized by:

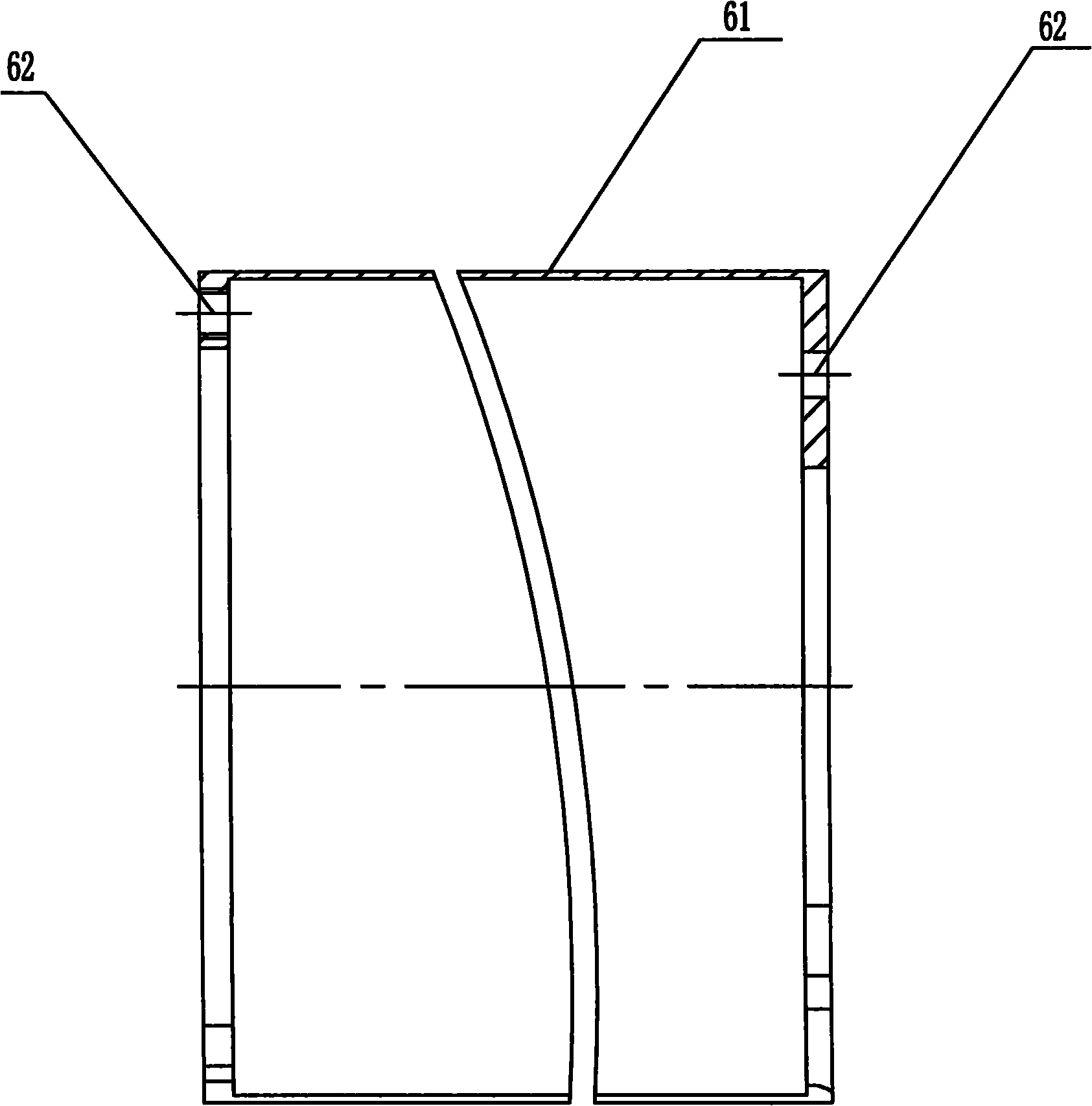

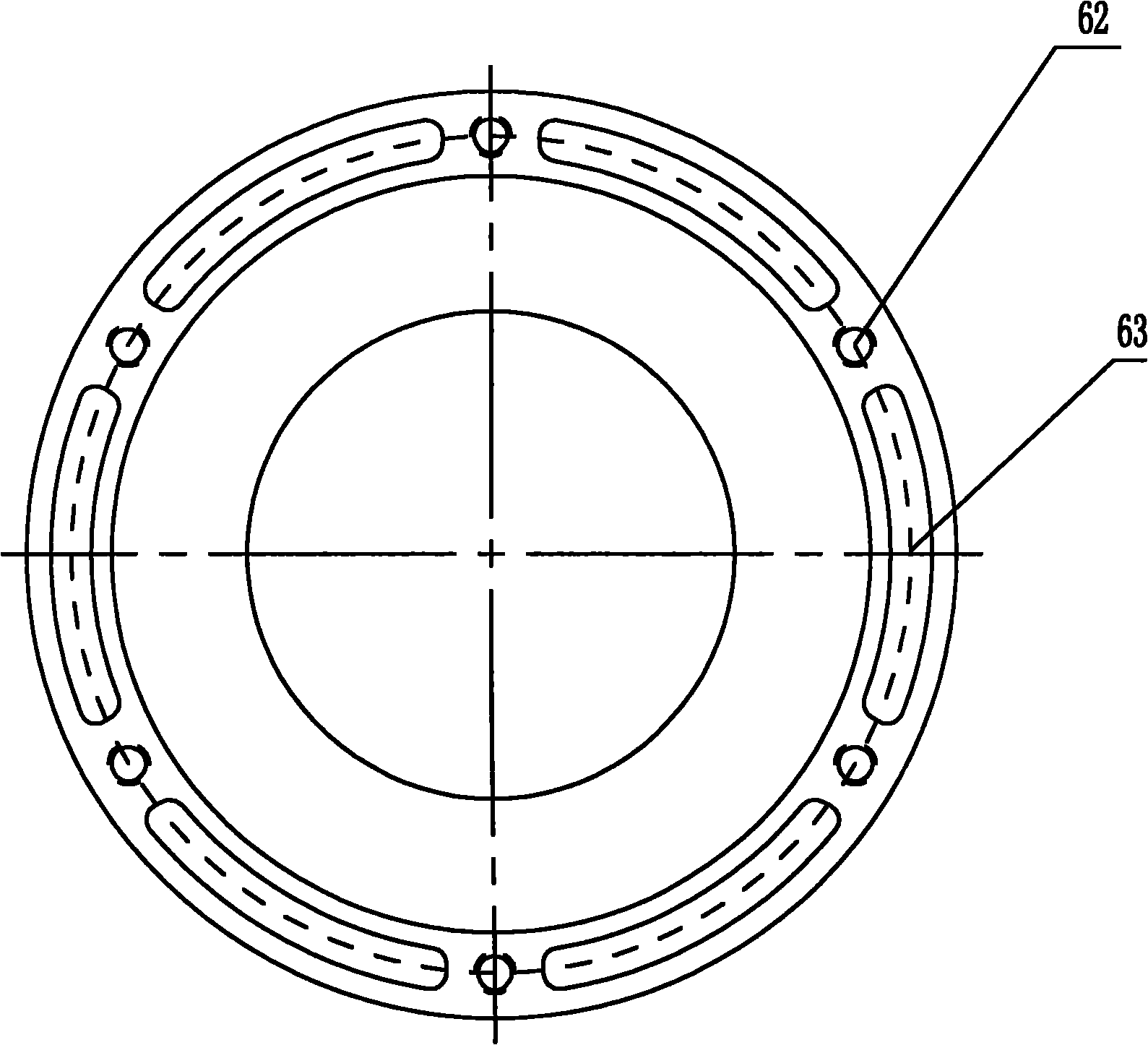

[0025] A shaft radiating sleeve 4 and a fan 8 are sequentially installed between the pump body 1 and the motor 9; the shaft radiating sleeve 4 is connected to the pump body 1, and the shaft radiating sleeve 4 has a round cylindrical shape in the middle, Round radiating fins are evenly distributed around the circumference; the said shaft radiating sleeve 4 is provided with a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com