Preparation method of low-VOC bonding resin

A technology for bonding resin and tackifying resin, applied in the direction of adhesive types, graft polymer adhesives, polymer adhesive additives, etc., can solve the problem of low VOC content, high VOC content, affecting performance and Safety performance and other issues, to achieve the effect of concise process route and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

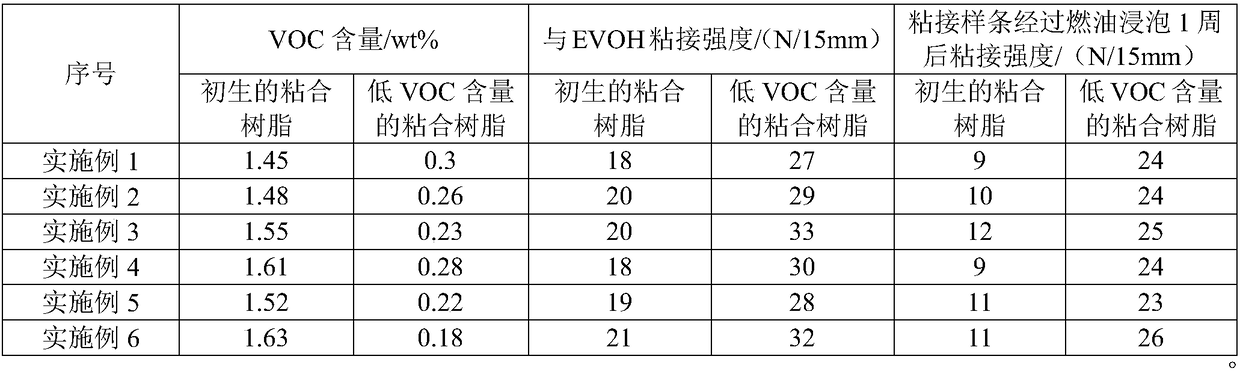

Embodiment 1~6

[0024] A preparation method of an adhesive resin with low VOC content, comprising the following steps:

[0025] (1) 75g of linear low-density polyethylene, 0.1g of maleic anhydride, 0.01g of 2,5-dimethyl-2,5 bis(tert-butylperoxy)hexane, 1g of C5 petroleum resin and ethylene-butylene 1 g of ethylene copolymer grafted maleic anhydride is mixed in proportion, then sent into a twin-screw extruder for melting, shearing, dehydration and drying after granulation and cooling to obtain the nascent adhesive resin;

[0026] (2) Send the adhesive resin into the supercritical device, pass through the purification solvent, first pressurize to 7-45MPa, then heat to convert the purification solvent into a supercritical fluid, and keep it in the supercritical state for 40min, and then remove it pressure, repeat the above step of pressurizing and heating 5 times, remove the VOC substances in the adhesive resin, and obtain the adhesive resin with low VOC content.

[0027] Wherein each embodimen...

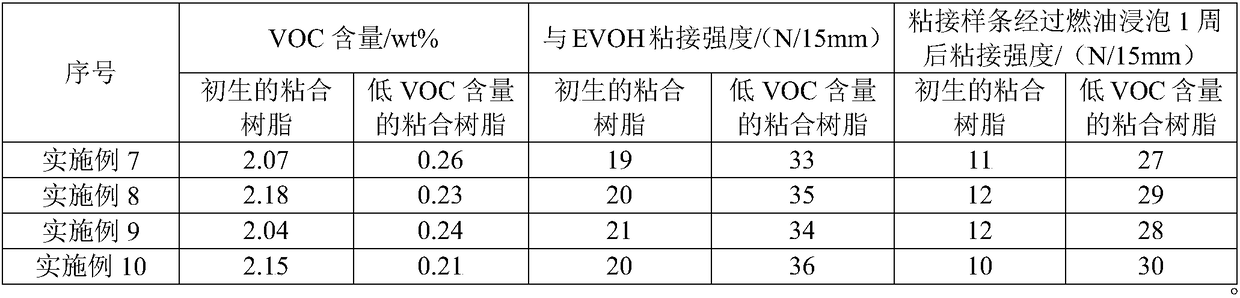

Embodiment 7~10

[0035] A preparation method of an adhesive resin with low VOC content, comprising the following steps:

[0036] (1) metallocene polyethylene 80g, maleic acid 2.5g, dicumyl peroxide 0.3g, C9 petroleum resin 6g and ethylene-octene copolymer grafted maleic anhydride 5g are mixed in proportion, then sent into bismuth The screw extruder melts, shears, and then granulates, cools, dehydrates and dries to obtain the primary adhesive resin;

[0037] (2) Put the nascent adhesive resin into the supercritical device, add the purification solvent, first pressurize to 7-45MPa, then heat to convert the purification solvent into a supercritical fluid, and keep it in the supercritical state for 20min, and then unload Remove the pressure, repeat the above step of pressurizing and heating 3 times, remove the VOC substances in the adhesive resin, and obtain the adhesive resin with low VOC content. Wherein the purification solvent, pressure and temperature used in each embodiment are shown in Tab...

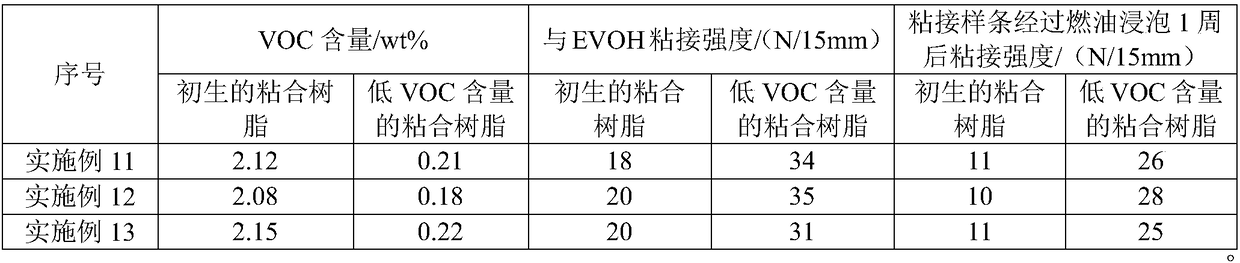

Embodiment 11~13

[0044] A preparation method of an adhesive resin with low VOC content, comprising the following steps:

[0045] (1) 28.5g of medium-density polyethylene, 66.5g of ultra-low-density polyethylene, 5g of maleic anhydride, 0.5g of dibenzoyl peroxide, 10g of hydrogenated C5 petroleum resin and ethylene-octene copolymer grafted horse 10 g of toric anhydride is mixed in proportion, then sent into a twin-screw extruder for melting, shearing, granulation, dehydration and drying after cooling to obtain the nascent adhesive resin;

[0046] (2) Send the nascent adhesive resin into a supercritical device, pass in a purification solvent and add an entrainer, first pressurize to 7-45MPa, heat to convert the purification solvent into a supercritical fluid, and keep it in a supercritical state for 10 minutes , Then the pressure is removed, and the above-mentioned pressurization and heating steps are repeated twice to obtain an adhesive resin with low VOC content. The purification solvent, ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com