Collecting pipe and processing method thereof

A processing method and header technology, applied in the field of fluid diversion devices in air-conditioning and refrigeration systems, can solve problems such as reduced product quality, uneven diversion, and reduced heat exchange capacity, so as to reduce the probability of failure and overcome the problem of branch nozzles Blocking and improving the energy efficiency of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

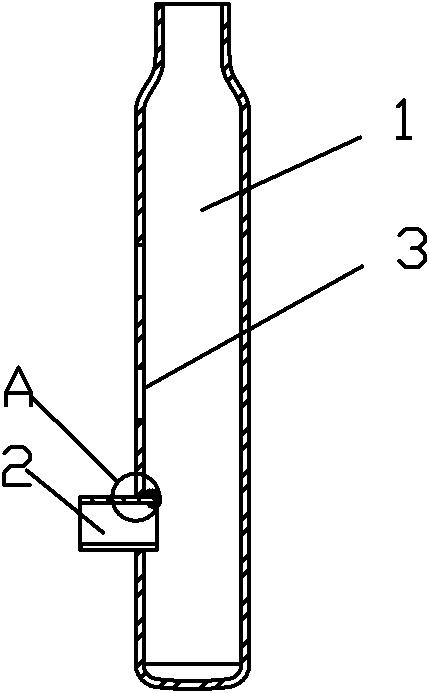

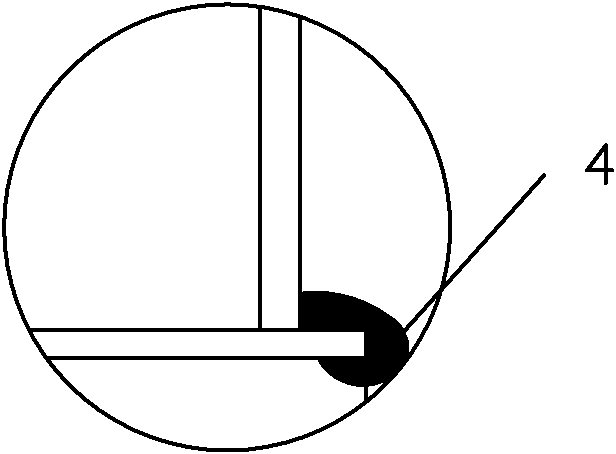

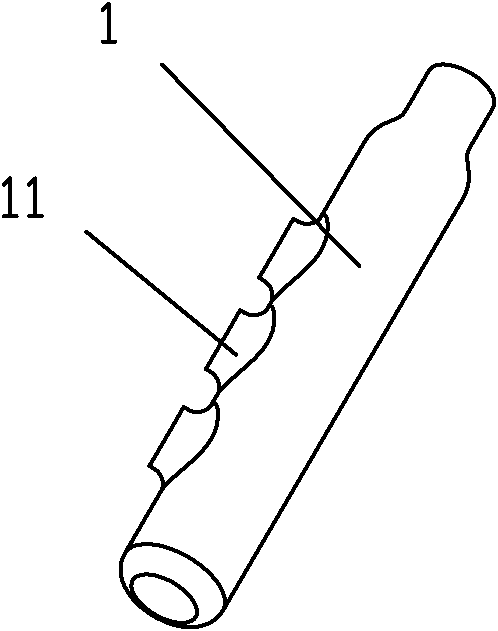

[0029] Collector of the present invention is welded by main pipe 1 and branch pipe 2, and the structure of main pipe is as image 3 As shown, three branch pipe holes 3 are provided on the main pipe, and outward branch pipe hole flanges 11 are provided on the branch pipe holes 3 . See Figure 4 , Figure 5 The branch pipe 2 is inserted into the main pipe from the branch pipe hole 3 of the main pipe 1. The outer diameter of the branch pipe matches the inner diameter of the branch pipe hole. , The solder pile 4 is stacked between the branch pipe and the flange of the branch pipe hole. There was no phenomenon of solder piles clogging the orifice.

[0030] The collecting pipe of the present invention is made by two processes of punching and edge drawing. A plurality of openings are punched on the blank tube wall of the collecting tube. The num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com